Africa 686 IBR Roof Sheet Making Machine-Cangzhou Longway International Trade Co., Ltd.|Precision, Efficiency, Innovation

Introduction

The Africa 686 IBR Roof Sheet Making Machine represents a significant advancement in the construction industry, offering a reliable and efficient solution for producing high-quality roofing materials. Developed by Cangzhou Longway International Trade Co., Ltd., this machine combines cutting-edge technology with user-friendly design to meet the evolving demands of modern construction projects. Whether you're working on residential, commercial, or industrial buildings, the Africa 686 IBR machine ensures precision, durability, and cost-effectiveness. In this article, we will explore the product's features, advantages, technical specifications, applications, and the company's commitment to innovation.

Product Overview

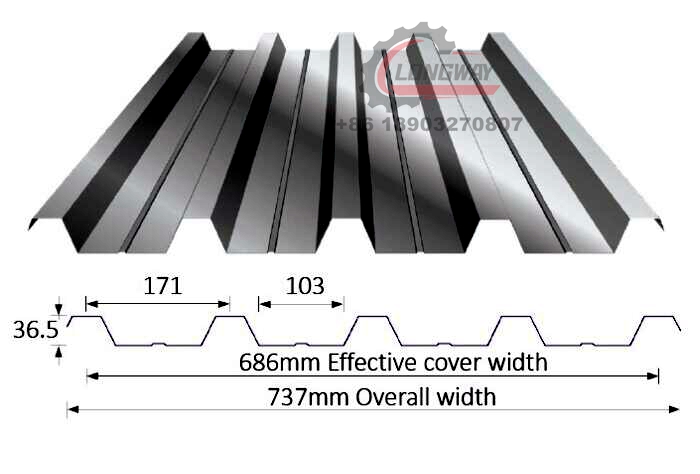

The Africa 686 IBR Roof Sheet Making Machine is designed to produce interlocking Batten Roof (IBR) sheets, which are widely used in construction due to their strength, lightweight, and aesthetic appeal. The machine is equipped with advanced roll forming technology, allowing it to produce standard profiles as well as custom designs tailored to specific project requirements. Its high production capacity ensures that even large-scale projects can be completed efficiently, reducing downtime and labor costs. The following images provide a closer look at the machine's design and functionality:

Figure 1: Overview of the Africa 686 IBR Roof Sheet Making Machine

Figure 2: Detailed View of the Machine's Roll Forming Components

Figure 3: Finished IBR Roof Sheets Produced by the Machine

Key Features and Advantages

1. Versatile Profile Options

The Africa 686 IBR machine is capable of producing a wide range of standard profiles, making it suitable for various roofing applications. Additionally, the machine supports custom design options, allowing users to create unique shapes and patterns to meet specific project requirements. This flexibility ensures that the machine can adapt to the diverse needs of the construction industry.

2. High Production Capacity

One of the standout features of the Africa 686 IBR machine is its high production capacity. With advanced automation and optimized manufacturing processes, the machine can produce a large volume of roofing sheets in a short amount of time. This not only enhances productivity but also reduces the overall cost per unit, making it a cost-effective solution for businesses.

3. Energy Efficiency and Cost-Effectiveness

The machine is designed with energy efficiency in mind, utilizing advanced technologies to minimize power consumption while maintaining high output. This feature not only reduces operational costs but also aligns with the growing emphasis on sustainable manufacturing practices. By lowering energy usage, the Africa 686 IBR machine contributes to a more environmentally friendly production process.

4. Durability and Precision

Constructed with high-quality materials and precision engineering, the Africa 686 IBR machine ensures long-term durability and reliable performance. The roll forming system is designed to produce consistent and accurate profiles, minimizing material waste and ensuring that each roofing sheet meets the required specifications. This level of precision is essential for maintaining the structural integrity and aesthetic appeal of the final product.

5. User-Friendly Interface

The machine features an intuitive control system that simplifies operation and maintenance. Users can easily adjust parameters such as sheet thickness, length, and profile design through a user-friendly interface. This accessibility makes the machine suitable for both experienced operators and those new to the industry.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | Africa 686 IBR |

| Material Compatibility | Galvanized steel, aluminum, and other lightweight metals |

| Sheet Thickness | 0.4 - 1.2 mm |

| Sheet Width | 750 - 1200 mm |

| Production Speed | Up to 15 meters per minute |

| Power Supply | 380V, 50Hz, 3-phase |

| Machine Dimensions | Approx. 12m x 2.5m x 1.8m |

| Weight | Approx. 5 tons |

Applications and Industry Use Cases

The Africa 686 IBR Roof Sheet Making Machine is versatile and suitable for a wide range of applications, including:

- Residential Construction: Ideal for producing lightweight, durable roofing sheets for homes and small buildings.

- Commercial Buildings: Suitable for large-scale projects such as shopping centers, warehouses, and office complexes.

- Industrial Facilities: Efficiently produces robust roofing materials for factories, storage facilities, and manufacturing plants.

- Infrastructure Projects: Used in the construction of bridges, tunnels, and other civil engineering structures.

According to the National Institute of Standards and Technology (NIST), "Precision in manufacturing processes is critical for ensuring the structural integrity and longevity of construction materials." The Africa 686 IBR machine aligns with these standards by delivering consistent quality and reliability, making it a trusted choice for professionals in the industry.

Company Background: Cangzhou Longway International Trade Co., Ltd.

Cangzhou Longway International Trade Co., Ltd. is a leading manufacturer and supplier of industrial machinery, specializing in roll forming equipment for the construction and manufacturing sectors. With years of experience and a commitment to innovation, the company has established itself as a reliable partner for businesses seeking high-quality solutions. Their products are designed to meet international standards, ensuring that they can compete in the global market.

As stated by NIST, "Companies that prioritize research and development in manufacturing technologies are better positioned to drive economic growth and technological advancement." Cangzhou Longway International Trade Co., Ltd. exemplifies this principle by continuously investing in R&D to improve their products and services, ensuring that they remain at the forefront of the industry.

Conclusion

The Africa 686 IBR Roof Sheet Making Machine is a testament to the advancements in modern manufacturing technology. With its versatile design, high production capacity, and user-friendly features, this machine offers a comprehensive solution for the construction industry. Whether you're looking to enhance productivity, reduce costs, or meet specific project requirements, the Africa 686 IBR machine is an excellent choice. By partnering with Cangzhou Longway International Trade Co., Ltd., businesses can ensure they have access to reliable, high-quality equipment that meets the highest standards of performance and durability.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025