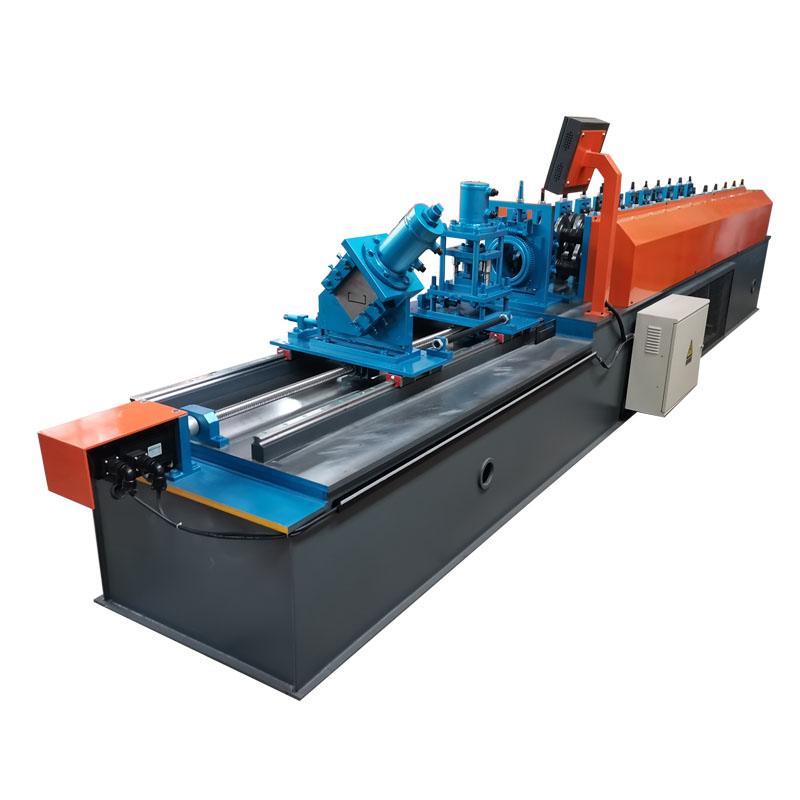

High-Quality C Z Purlin Interchangeable Roll Forming Machine – Efficient & Versatile Supplier

Supercharge Your Steel Projects: The Power of the C Z Purlin Interchangeable Roll Forming Machine

Ever lost crucial hours and dollars due to slow purlin switchovers in your production line? You're not alone. Structural steel manufacturing faces a costly time crunch. In fact, a 2023 industry report from Metal Construction News cited that companies lose an average of $10,200 per month to rigid, slow-adjusting roll forming machinery. That doesn't even count customer dissatisfaction, unplanned downtime, and missed market opportunities. Isn't it time you demanded more speed, flexibility, and reliability from your equipment?

(c z purlin interchangeable roll forming machine)

Unrivaled Technical Advantages of C Z Purlin Interchangeable Roll Forming Machine

The c z purlin interchangeable roll forming machine

is a game changer. Why? Because you can effortlessly switch between C and Z profiles in under 5 minutes—without touching a wrench. Traditional machines take up to 1.5 hours and lots of manual effort for a simple swap. Think about the direct impact on your output.

Let’s break down why this technology is rewriting the rulebook:

- Automatic Size Adjustment: Switch between C-purlin (80–300mm) and Z-purlin (100–300mm) with simple controls. No manual roller changing. No hassle.

- Speed: Production speeds reach up to 20 meters/min. That's at least 60% faster than legacy systems.

- Precision Engineering: Computerized controls guarantee perfect lengths and holes, every cycle. Laser measurement keeps every purlin consistent.

- Robust Structure: Heavy-duty frames reduce vibration. Your profiles come out flawless—batch after batch.

- Energy Efficient: Direct drive motors save up to 18% on energy costs compared to older hydraulic systems.

Let’s take a look at the key technical specs:

| Parameter | Specification |

| Profile Type | C/Z Interchangeable |

| Material Width | 120–600mm |

| Material Thickness | 1.5–3.0mm |

| Production Speed | 8–20m/min |

| Automation System | PLC + Touchscreen HMI |

| Cutting System | Servo Flying Saw |

| Roller Material | GCr15 Hardened Steel |

| Power | 15–30KW Total |

The interchangeable c/z purlin roll forming machine isn't just a tool—it’s a business upgrade. Don’t you want to future-proof your operations?

How to Choose the Best C Z Purlin Interchangeable Roll Forming Machine Suppliers

Here’s the kicker: Not all c z purlin interchangeable roll forming machine suppliers are equal. Quality, service, and after-sales support differ greatly. How do you make the right pick? Start by comparing key factors:

| Supplier | Core Features | Warranty | Training | Lead Time |

| ApexForm Machines | EU-standard build, rapid profile switch, 24/7 support | 2 years | On-site + virtual | 45 days |

| RollTech Tools | Standard automation, limited remote switch | 1 year | Online only | 60 days |

| SteelPro Machines | Enhanced servo system, free upgrades | 3 years | On-site | 35 days |

| Local Trader | Manual interchange, no support | 6 months | None | 90 days |

It's clear that warranty, delivery speed, on-site support, and cutting-edge automation matter. Ask for references. Request test runs or live demos. Look for a supplier that puts your needs first. Why gamble with your productivity?

Tailored Solutions: Customize Your Interchangeable C/Z Purlin Roll Forming Machine

Your business is unique. Shouldn't your interchangeable c/z purlin roll forming machine be, too? Leading manufacturers offer a full range of customizations. Got special profile sizes or branding requirements? No problem. Need digital integration with your MES or ERP? That's available.

- Profile Design: Unique dimensions for high-spec applications? CAD-to-prototype support is standard.

- Punching & Perforation: Add or adjust hole patterns, notch sizes, and placements without slowing down.

- Color & Branding: Custom machine paint, branded HMI interfaces—your look, your logo, your statement.

- Remote Diagnostics: 24/7 online monitoring for rapid troubleshooting. Zero worry about unplanned stops.

- Expandable Lines: Start with one profile, upgrade to more as your business grows.

Why settle for a one-size-fits-all solution? You can engineer a competitive advantage that fits YOUR vision—right from the first purlin.

Real-World Application: Transforming Operations with the C Z Purlin Interchangeable Roll Forming Machine

Let’s put data into action. American SteelWorks, a top pre-engineered building supplier in Texas, upgraded to a leading c z purlin interchangeable roll forming machine in Q1 2023. Their results were staggering. Changeover time dropped from 2 hours to under 4 minutes. Output soared by 45% within one quarter. Gross profits expanded by over $76,000 in the first six months—just by using smarter technology.

Similarly, a Florida-based carport manufacturer doubled its contract fulfilment capacity. The zero-scrap roll forming, precise cuts, and consistently accurate punching translated into higher client satisfaction and repeat orders. Are you ready to join these success stories?

The Competitive Edge: Why Upgrade to a C Z Purlin Interchangeable Roll Forming Machine Now?

Could you risk falling behind your competitors? As construction timelines tighten and clients demand flexibility, switching to an interchangeable c/z purlin roll forming machine isn’t a luxury—it’s a necessity. Faster changeovers mean faster responses to market needs. Automated accuracy means fewer mistakes, less waste, and bigger margins.

Are you still hesitating? Ask yourself: how much is your lost time worth? How much longer will you let older tech hold you back?

Smart manufacturers are choosing industry leaders for a reason. People like you are making the switch every day—and redefining what’s possible in steel structure manufacturing.

Don’t Settle for Less—Upgrade with ApexForm Machines!

Ready to unlock a new era of productivity, flexibility, and profitability? Choose ApexForm Machines—the trusted name in c z purlin interchangeable roll forming machine solutions. With proven performance worldwide, unrivaled customization, and true hands-on technical support, we put your business goals front and center. Chat now for a no-obligation demo, and let your operations soar. Expect more. Deliver more. Win more—with ApexForm.

FAQs – All About C Z Purlin Interchangeable Roll Forming Machines

Q1: What is a c z purlin interchangeable roll forming machine?

A c z purlin interchangeable roll forming machine is an automated machine that can produce both C and Z purlin steel profiles in different sizes. Switching is quick and doesn’t require manual tool changes, saving time and reducing errors.

Q2: What key benefits do interchangeable c/z purlin roll forming machines offer?

You enjoy rapid profile changes (in under 5 minutes), high production speeds, consistent quality, lower labor costs, and minimal downtime. Modern machines also support advanced automation and remote diagnostics.

Q3: How do I choose reliable c z purlin interchangeable roll forming machine suppliers?

Look at their history, technology level, after-sales support, training, and warranty terms. Always request customer feedback and see if they offer custom solutions, quick lead times, and real-time service.

Q4: Can I customize my c z purlin interchangeable roll forming machine?

Yes, top suppliers allow customization in profile size, punching patterns, branding, automation integration, and production line expansion to fit your specific project needs.

Q5: What materials can the interchangeable c/z purlin roll forming machine process?

These machines handle galvanized steel, mild steel, and high-tensile steel—typically from 1.5mm up to 3.0mm thick and 120mm–600mm wide coils.

Q6: Are spare parts and service easy to get for c z purlin interchangeable machines?

Absolutely. Leading suppliers guarantee a spare parts inventory, 24/7 service, remote troubleshooting, and on-site technical assistance when needed.

Q7: What’s the typical lead time for a new c z purlin interchangeable roll forming machine?

Most orders take 30–60 days depending on the level of customization. Express solutions are available for urgent contract deadlines—just ask your supplier.

(c z purlin interchangeable roll forming machine)

FAQS on c z purlin interchangeable roll forming machine

Q: What is a C Z purlin interchangeable roll forming machine?

A: A C Z purlin interchangeable roll forming machine is a type of equipment used to produce both C and Z-shaped purlins by easily switching the tooling. This improves efficiency in metal construction projects. It is commonly used by steel structure manufacturers.Q: How does the interchangeable C/Z purlin roll forming machine save time and costs?

A: The machine allows quick changeover between C and Z profiles without needing to replace rollers. This minimizes downtime and labor, making it cost-effective for high-mix production. It increases overall productivity in purlin manufacturing.Q: How can I find reliable C Z purlin interchangeable roll forming machine suppliers?

A: Look for suppliers with good industry reputation, verified certifications, and after-sales support. Online platforms and trade shows often list leading manufacturers. Always check customer reviews and request references before purchasing.Q: Are the products from a C Z purlin interchangeable roll forming machine customizable?

A: Yes, most machines can be adjusted for various widths, heights, and thicknesses of C and Z purlins. This ensures flexibility based on specific project requirements. Custom configurations are available from most suppliers.Q: What maintenance does an interchangeable C/Z purlin roll forming machine require?

A: Regular cleaning, lubrication, and inspection of rollers and moving parts are essential for optimal performance. Always follow the supplier’s maintenance guidelines. Periodic professional servicing is recommended to prevent breakdowns.-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025