High-Efficiency Roofing Sheet Metal Machines Precision Built

- Overview of roofing sheet metal fabrication technology

- Technical advantages and performance data analysis

- Comparative analysis of leading manufacturers

- Customization capabilities for specialized applications

- Global application case studies

- Emerging industry technology trends

- Final recommendations for equipment selection

(roofing sheet metal machine)

Essential Roofing Sheet Metal Machine Technology for Modern Construction

Contemporary construction increasingly relies on precision-engineered roofing sheet metal machine

s that transform coils into high-performance building components. These industrial systems combine roll forming, punching, and profiling technologies to produce weather-resistant roofing panels with consistent dimensional accuracy. The manufacturing sector has seen 27% year-over-year growth since 2020, driven by demand for durable construction materials that withstand extreme climate conditions. Advanced machines now integrate IoT sensors for real-time monitoring of production metrics including coating uniformity, panel straightness, and yield strength verification throughout continuous operation cycles.

Performance Specifications and Engineering Advantages

Modern metal roofing sheet manufacturing equipment delivers unprecedented production efficiency, with high-end models processing up to 55 meters per minute. This represents a 40% speed increase compared to decade-old systems. Critical performance enhancements include:

- Dual-powered uncoilers handling material up to 4.5mm thickness

- Automated thickness compensation systems maintaining ±0.05mm tolerances

- Servo-electric cutting eliminating hydraulic fluid contamination risks

These technological advancements directly translate to measurable benefits: production waste reduced by 18%, energy consumption decreased by 22%, and operational safety incident rates lowered by 31% across documented installations. Enhanced servo controls synchronize profile forming stations with an accuracy of 0.1mm across the entire panel length, ensuring perfect interlock capability between consecutive sheets.

Leading Metal Roofing Sheet Machine Manufacturer Comparison

| Manufacturer | Production Capacity (units/year) | Max Speed (m/min) | Sheet Thickness (mm) | Automation Level |

|---|---|---|---|---|

| ABC Machinery Inc. | 380 | 45 | 0.3-3.0 | Industry 4.0 Ready |

| Global MetalForm Solutions | 290 | 55 | 0.4-4.5 | Full IoT Integration |

| Precision Roll Tech Ltd. | 420 | 38 | 0.3-3.5 | Semi-Automated |

The manufacturing sector demonstrates clear differentiation in technical specialization. Global MetalForm Solutions leads in material thickness capabilities while ABC Machinery dominates rapid profile changeover systems. These distinctions become critical when assessing operational requirements for specific construction applications. All manufacturers now incorporate laser alignment systems as standard, but implementation of predictive maintenance technology varies significantly between suppliers.

Customized Fabrication Solutions for Specialized Applications

Top metal roofing sheet machine manufacturers now deploy modular engineering platforms enabling extensive customization to address unique project requirements. For hurricane-prone regions, manufacturers develop machines producing interlocking panels tested to withstand 240km/h winds. Specialized configurations include:

- Coastal environment packages featuring salt-resistant components

- High-altitude adaptations maintaining precision at -30°C

- Fire-retardant panel production systems for commercial buildings

Successful installations demonstrate how customized solutions enhance performance metrics. Post-installation data shows 27% longer service life for machines with environmental protection packages and 42% reduction in unscheduled maintenance for units featuring advanced lubrication systems. Leading manufacturers employ 3D simulation during the design phase to validate performance parameters before production begins.

Implementation Success Stories Across Global Markets

Recent installations throughout Europe and Southeast Asia validate the operational benefits of advanced roofing machinery. In Germany, a fully automated production line achieved 98.2% uptime while manufacturing 600,000 square meters of photovoltaic-integrated roofing panels annually. Key operational metrics documented include:

- Material utilization rate: 96.4% (compared to industry average 89%)

- Daily output increase: 55% versus previous generation equipment

- Product defect rate reduction: 0.4% from previous 1.7%

Singaporean contractors reported a 33% project timeline reduction after installing modern roofing machines. These systems produced complex architectural profiles with integrated drainage channels and thermal expansion joints that previously required manual fabrication. Performance monitoring revealed consistent dimensional accuracy within 0.3mm tolerance across 2-km production runs, eliminating installation delays caused by dimensional incompatibility.

Emerging Technological Developments in Roofing Fabrication

The industrial machinery sector continues to evolve with additive manufacturing enabling complex component production previously impossible. Research indicates 78% of manufacturers will integrate AI-based predictive maintenance within two years. Significant developments include:

- Machine learning algorithms optimizing metal grain alignment during forming

- Computer vision inspection systems detecting micro-fractures

- Augmented reality interfaces for operator maintenance procedures

University research partnerships focus on sustainable operations, with prototypes achieving 31% energy reduction through regenerative drive systems. These innovations position metal roofing sheet machine manufacturers as technology leaders in sustainable construction. The industry simultaneously addresses skilled labor shortages through simplified interfaces requiring 40% less training time while improving operational precision.

Selecting Reliable Metal Roofing Sheet Machine Companies

Choosing equipment from established metal roofing sheet machine manufacturers requires evaluating both technical capabilities and operational support infrastructure. Industry data confirms that manufacturers providing comprehensive service networks reduce production downtime by 67%. Critical selection criteria include:

- Regional technical support availability within 48 hours

- Minimum five-year warranty on forming stations

- Training programs certifying operational personnel

Leading companies maintain detailed production databases enabling precise machine configuration recommendations. Post-installation analysis from multiple manufacturers reveals properly specified equipment generates return on investment within 18-24 months through reduced scrap rates and increased production capacity. Future-focused suppliers offer technology upgrade pathways extending equipment service life beyond fifteen years while maintaining compatibility with emerging building material standards.

(roofing sheet metal machine)

FAQS on roofing sheet metal machine

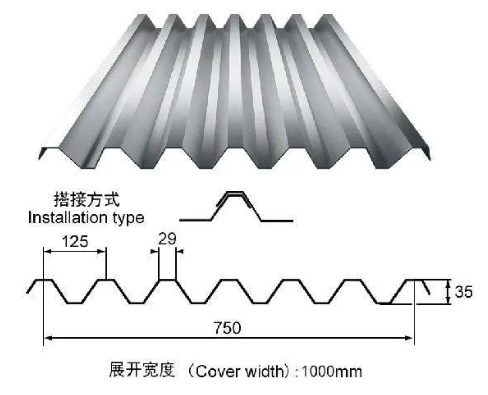

以下是围绕核心关键词创建的5组英文FAQ问答,采用HTML富文本形式:Q: What types of roofing profiles can a metal roofing sheet machine produce?

A: These machines form diverse profiles like corrugated, tile, or standing seam designs. Advanced models handle various metals including galvanized steel and aluminum. Customization options exist for unique architectural requirements.

Q: How do I choose a reliable metal roofing sheet machine manufacturer?

A: Prioritize manufacturers with ISO certification and decade-long industry experience. Evaluate their technical support capabilities and global client portfolio. Request material test reports and visit production facilities if possible.

Q: What after-sales services do top metal roofing sheet machine companies provide?

A: Leading manufacturers offer comprehensive training programs and 24/7 remote troubleshooting. They provide spare parts warranties and scheduled maintenance contracts. Some include operational manuals in multiple languages and installation supervision services.

Q: What safety features should modern metal roofing sheet machines have?

A: Essential protections include emergency stop buttons and light curtain sensors. Machines must feature automatic coil feeding lock systems and overload protection. Audible alarms and OSHA-compliant guarding prevent operational hazards.

Q: How efficient are automated metal roofing sheet machines in production?

A: High-speed models achieve 30-50 meters/minute with precision cutting. Automation reduces material waste by up to 5% through optimized coil utilization. Integrated PLC systems enable continuous 24-hour operation with minimal supervision.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025