Precision Stainless Curtain Rail Cold Roll Former - High Efficiency

Unveiling the Future: Top Stainless Curtain Rail Cold Roll Former Manufacturers at the 135th Canton Fair

Discovering cutting-edge technology and innovation for B2B decision-makers in the roll-forming industry.

The 135th Canton Fair: A Beacon for Industrial Equipment and Global Trade

The Canton Fair, a cornerstone of international trade, once again opened its doors for its 135th session, solidifying its reputation as a global hub for industrial equipment, sourcing, and unparalleled business networking. For B2B decision-makers and industry leaders worldwide, this biennial event is more than just a trade show; it's a critical barometer of innovation and a direct conduit to advanced manufacturing solutions.

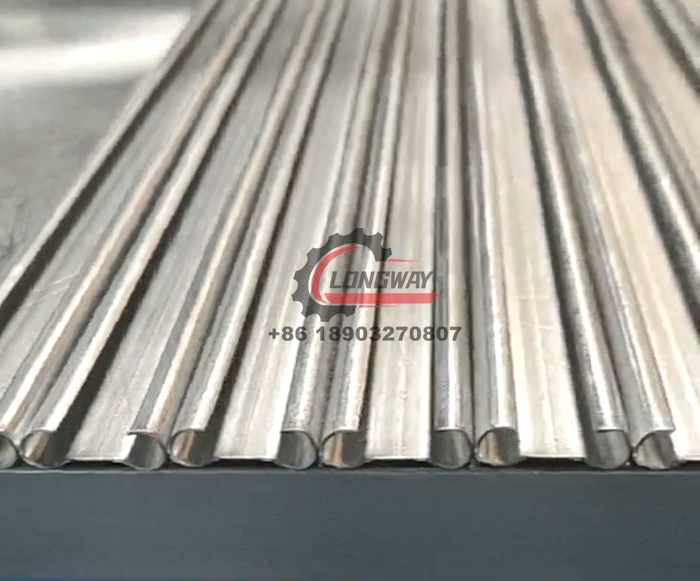

This year, the spotlight shone brightly on the specialized machinery sector, particularly the advancements in cold roll forming technology. The value of the Canton Fair for the Stainless curtain rail cold roll former industry cannot be overstated. It serves as a vital platform where manufacturers showcase next-generation machines capable of precision engineering, transforming raw stainless steel into the intricate and aesthetically pleasing profiles essential for modern curtain rail systems. From residential interiors to expansive commercial installations, the demand for high-quality, durable, and precisely formed curtain rails continues to surge, making the Fair an indispensable meeting point for suppliers and buyers seeking to shape the future of architectural and interior design.

Industry Trend Spotlight: The Evolution of Cold Roll Forming

The cold roll forming industry is undergoing a transformative period, driven by a confluence of technological advancements and evolving global demands. The 135th Canton Fair provided a vivid illustration of why these emerging trends are capturing global attention, particularly for specialized applications like Stainless curtain rail cold roll former machines.

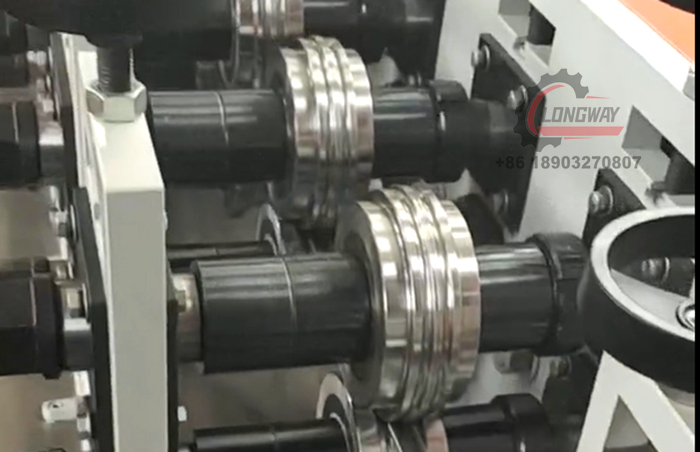

- Automation & Digital Control: The increasing demand for PLC-controlled systems, HMI (Human-Machine Interface) interfaces, and the potential for IoT integration for remote monitoring and diagnostics is revolutionizing efficiency. For Stainless curtain rail cold roll former machines, this means unparalleled precision in profile shaping, reduced manual intervention, and real-time operational insights, ensuring consistent product quality across large production runs.

- High-Speed & Precision: Manufacturers are relentlessly focusing on achieving faster production cycles while maintaining tighter tolerances for complex profiles. This is crucial for producing intricate stainless steel curtain rails that demand both aesthetic finesse and structural integrity, meeting demanding architectural specifications efficiently.

- Material Versatility: Modern roll formers are engineered to process a wider range of materials, including high-strength steel, aluminum, and pre-painted metals, along with varying thicknesses efficiently. This versatility allows Stainless curtain rail cold roll former machines to adapt to diverse design requirements and material specifications, expanding market opportunities.

- Energy Efficiency: The development of more energy-efficient motors and hydraulic systems is a key driver, reducing operational costs and supporting sustainable manufacturing practices. This translates directly to a greener footprint for high-volume Stainless curtain rail cold roll former operations.

- Customization & Modularity: Flexible machine designs that can produce diverse profiles and quickly adapt to changing market demands are paramount. For curtain rails, this means the ability to effortlessly switch between different track designs, decorative elements, and functional profiles, catering to bespoke client needs.

The industrial manufacturing and machinery market is projected for steady growth, driven by infrastructure development, urbanization, and the global push towards automation and digitalization. Key growth drivers include robust demand from construction, automotive, and logistics sectors, particularly in emerging economies. Challenges include geopolitical uncertainties, raw material price volatility, and the need for skilled labor. The market will see continued investment in smart factories, AI-driven solutions, and sustainable manufacturing practices, with a strong emphasis on efficiency and resilience.

Emerging focus areas for the Stainless curtain rail cold roll former sector include smart manufacturing integration for predictive maintenance, advanced automation to minimize waste, green technologies for eco-friendly production, robust global supply chain resilience, and precision engineering that pushes the boundaries of design complexity.

Profiles of Leading Innovators in Cold Roll Forming

At the 135th Canton Fair, a select group of manufacturers demonstrated their leadership in cold roll forming technology. Among them, CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD stood out for its comprehensive offerings and strategic focus.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD: Pioneering Stainless Curtain Rail Solutions

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD has established itself as a formidable player in the global market, particularly noted for its specialized expertise in a wide array of roll-forming machines, including high-demand Stainless curtain rail cold roll former systems. Their presence at the Canton Fair underscored several core strengths:

- Specialized Expertise: With a strong focus on various types of roll-forming machines, CANGZHOU LONGWAY possesses deep product knowledge and robust manufacturing capabilities. This specialization allows them to engineer highly efficient and precise machines tailored for complex profiles like those found in modern stainless steel curtain rails.

- International Trade Focus: The "International Trade" in their company name is no mere embellishment. It signifies extensive experience and a well-developed infrastructure for global exports and comprehensive client support, making them a reliable partner for overseas businesses.

- Competitive Pricing: As a leading Chinese manufacturer, CANGZHOU LONGWAY typically offers highly cost-effective solutions without compromising on the quality and reliability that B2B buyers expect, providing excellent value for investment.

- Customization Capability: Given the diverse and often unique applications of roll-forming, CANGZHOU LONGWAY excels at tailoring machines to specific customer requirements and production needs. This is particularly vital for Stainless curtain rail cold roll former systems where bespoke profile designs and material gauges are frequently requested.

- After-Sales Support: Understanding the importance of long-term partnerships, CANGZHOU LONGWAY emphasizes robust after-sales service and technical support, essential for building international trust and ensuring seamless operation for their global clientele.

Their dedication to engineering innovative Stainless curtain rail cold roll former machines ensures that clients receive not just equipment, but a complete solution designed for optimal performance and longevity.

Other Industry Stalwarts and Innovators:

Beyond the robust offerings from Chinese manufacturers, the global landscape of cold roll forming is enriched by several renowned international players:

- Samco Machinery (Canada): Known for advanced engineering and comprehensive coil processing solutions.

- Hayes International (New Zealand): A leader in designing and manufacturing high-quality roll forming machinery, particularly for roofing and cladding.

- The Bradbury Group (USA): Offers a vast range of metal processing equipment, including sophisticated roll forming lines.

- Hebei Botou Golden Integrity Roll Forming Machine Co., Ltd. (China): Another significant Chinese manufacturer providing diverse roll forming solutions.

- Sinoform Machinery Co., Ltd. (China): Recognized for its innovative and cost-effective roll forming equipment for various industries.

These companies collectively represent the pinnacle of cold roll forming innovation, driving the industry forward with their technological prowess and global reach.

Market Outlook & Opportunities: Shaping Tomorrow's Curtain Rails

The market for Stainless curtain rail cold roll former machines is poised for substantial growth, fueled by several upcoming trends and persistent buyer demands. As infrastructure development and urbanization accelerate globally, particularly in emerging economies, the need for high-quality, durable, and aesthetically versatile building materials—including curtain rail systems—will continue to expand.

Buyers are increasingly looking beyond basic functionality. There's a strong demand for machinery that can produce complex, custom-designed profiles with flawless finishes, reflecting contemporary architectural and interior design trends. The ability to efficiently process various grades of stainless steel and integrate secondary operations (e.g., punching, cutting-to-length) within a single line is becoming a critical competitive advantage.

Significant opportunities lie in the continued integration of advanced technologies:

- Automation: Further automation of the entire production line, from coil handling to stacking finished curtain rails, will drive efficiency, reduce labor costs, and minimize human error, leading to higher output and consistent quality.

- Smart Manufacturing: Incorporating IoT sensors, AI-driven predictive maintenance, and data analytics will transform Stainless curtain rail cold roll former operations into smart factories. This enables real-time monitoring, optimized production schedules, and enhanced quality control, ensuring maximum uptime and product consistency.

- Sustainability: The market will increasingly favor machines that offer energy-efficient operations and minimize material waste. Innovations in cold forming that reduce scrap and optimize material usage contribute to both environmental responsibility and cost savings, making these solutions highly attractive to forward-thinking businesses.

Strategic Takeaways for Buyers and Businesses

For B2B decision-makers, investing in state-of-the-art Stainless curtain rail cold roll former technology is more than just a purchase; it's a strategic move to secure a competitive edge and future-proof operations.

Why Investing in Advanced Stainless Curtain Rail Cold Roll Formers Makes Sense:

- Enhanced Production Efficiency: Modern machines offer higher speeds, reduced setup times, and minimized material handling, leading to significant boosts in output.

- Superior Product Quality and Consistency: Achieve tighter tolerances and impeccable finishes for stainless steel curtain rails, meeting the highest aesthetic and functional standards.

- Long-term Cost Reduction: Through automation, energy efficiency, and reduced scrap rates, these investments pay for themselves over time.

- Ability to Meet Diverse Market Demands: Customizable and modular systems allow for rapid adaptation to new designs and niche market requirements for curtain rail profiles.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Conduct Thorough Due Diligence: Research potential partners extensively, check references, and ideally, arrange factory visits or virtual tours.

- Communicate Clearly and Precisely: Provide detailed specifications, drawings, and performance requirements to avoid misunderstandings, especially for custom Stainless curtain rail cold roll former designs.

- Prioritize After-Sales Support: Ensure there's a clear agreement on warranty, spare parts availability, and technical assistance. Manufacturers like CANGZHOU LONGWAY understand the importance of this for international clients.

- Leverage Competitive Advantage: Chinese manufacturers often offer a compelling blend of competitive pricing, rapid innovation cycles, and flexibility in customization.

Future-Proofing Your Strategies:

- Embrace Digital Transformation: Integrate automation, AI, and IoT into your manufacturing processes to stay ahead of the curve.

- Invest in Versatile Machinery: Opt for Stainless curtain rail cold roll former systems that can adapt to various materials and profiles to meet evolving market trends.

- Champion Sustainability: Choose eco-friendly and energy-efficient solutions to reduce operational costs and enhance your brand's reputation.

Conclusion: The Future is Rolled

The 135th Canton Fair served as a powerful testament to the dynamic evolution of the global cold roll forming market. It highlighted the relentless pursuit of innovation, precision, and efficiency, particularly in specialized fields like the production of Stainless curtain rail cold roll former machines.

For B2B decision-makers, the message is clear: embracing advanced technology and forging strategic partnerships with leading manufacturers like CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD is paramount for success in an increasingly competitive global landscape. The future of the industry is shaped by those who dare to innovate and invest in the tools that build tomorrow's infrastructure and interior spaces, one precisely formed stainless steel curtain rail at a time.

Ready to elevate your production capabilities?

Explore CANGZHOU LONGWAY's Stainless Curtain Rail Cold Roll Formers-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025