High Precision Metal Coil Slitting Line & Steel Slitting Machine

Introduction to Advanced Slitting Technology

The metal processing industry relies heavily on precision and efficiency, especially when dealing with large volumes of coil materials. Central to this efficiency is the Metal coil slitting line steel slitting machine, a sophisticated system designed to cut wide metal coils into narrower strips of specific widths. These machines are indispensable for manufacturers requiring precise material dimensions for downstream operations, from automotive stamping to construction profiles. Our advanced slitting lines are engineered to handle a diverse range of materials, including stainless steel, galvanized steel, aluminum, and various non-ferrous metals, ensuring high accuracy and minimal material waste across countless applications.

The continuous evolution of material science and manufacturing demands has propelled the development of slitting technology, leading to machines that offer unparalleled operational speed, cutting precision, and material handling capabilities. This article delves into the intricate details, technical specifications, and industry applications of these vital systems, providing a comprehensive overview for technical decision-makers and engineers.

The Manufacturing Process of a Metal coil slitting line steel slitting machine

The creation of a high-performance Metal coil slitting line steel slitting machine involves a meticulous multi-stage manufacturing process, ensuring robust construction, unparalleled precision, and extended service life. Each component undergoes rigorous quality control to meet stringent industry standards.

Key Manufacturing Steps:

- Design and Engineering: Utilizing advanced CAD/CAM software, components are designed with finite element analysis (FEA) to ensure structural integrity and optimal performance under various loads. Material selection is critical, often involving high-strength alloy steels for critical components like arbors and slitter knives.

- Material Sourcing & Preparation: High-grade tool steels (e.g., D2, H13) for slitter knives, high-tensile structural steel for machine frames, and precision-ground bearing steels for rotating parts are sourced from certified suppliers. Materials undergo ultrasonic testing to detect internal flaws.

-

Component Manufacturing:

- Casting/Forging: Large structural components, such as gear housings and some frame elements, may be precision cast or forged to achieve superior mechanical properties and internal homogeneity.

- CNC Machining: Critical parts like slitter arbors, gear shafts, and precision spacers are manufactured using state-of-the-art CNC machining centers. This ensures tolerances as tight as ±0.005 mm, vital for slitting accuracy.

- Heat Treatment: Slitter knives and wear parts undergo specialized heat treatments (e.g., induction hardening, nitriding) to achieve desired hardness, wear resistance, and toughness, extending their service life significantly.

- Grinding and Lapping: Precision surfaces, especially those in contact with the material or other moving parts, are meticulously ground and lapped to achieve mirror finishes, minimizing friction and maximizing operational smoothness.

- Assembly: Skilled technicians assemble the various modules—decoiler, leveller, slitter head, tension unit, recoiler—with precision. Alignment checks are performed at every stage using laser alignment tools.

-

Testing and Quality Assurance:

- Functional Testing: Each machine undergoes extensive functional testing, simulating actual production conditions with various coil materials and thicknesses.

- Performance Benchmarking: Key performance indicators (KPIs) such as cutting speed, burr height, width tolerance, and strip edge quality are measured and compared against design specifications.

- Standards Compliance: Our machines are built to conform to international standards such as ISO 9001 for quality management, ANSI B11.1 for safety, and relevant CE directives for European markets, ensuring both performance and operational safety.

The expected service life of our slitting lines typically exceeds 20-25 years with proper maintenance, a testament to the robust manufacturing processes and quality materials employed.

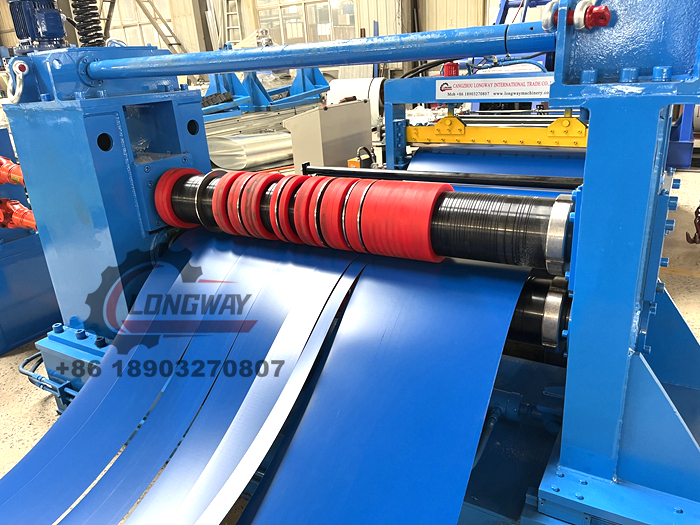

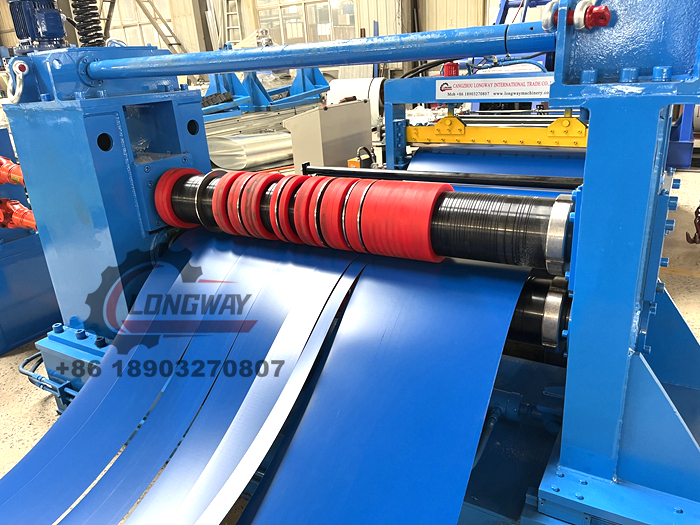

Figure 1: High-precision slitter head, a core component manufactured with CNC excellence.

Figure 1: High-precision slitter head, a core component manufactured with CNC excellence.

Industry Trends and Market Dynamics

The landscape for Metal coil slitting line steel slitting machine technology is rapidly evolving, driven by several key industry trends:

- Increased Automation and IoT Integration: Modern slitting lines increasingly incorporate advanced automation, robotics, and Industrial IoT (IIoT) capabilities. This allows for remote monitoring, predictive maintenance, and seamless integration with broader manufacturing execution systems (MES), leading to optimized throughput and reduced downtime.

- Handling of High-Strength and Advanced Materials: The demand for materials like Advanced High-Strength Steels (AHSS) and specialized alloys in automotive, aerospace, and construction sectors necessitates slitting lines designed for harder, tougher materials. This requires enhanced machine rigidity, more robust slitter tooling, and higher power drive systems.

- Focus on Energy Efficiency: With rising energy costs and environmental concerns, manufacturers are prioritizing machines that offer superior energy efficiency. This includes servo-driven systems, optimized motor designs, and regenerative braking technologies that minimize power consumption during operation.

- Enhanced Precision and Waste Reduction: Industries are demanding ever-tighter tolerances and minimal material waste. This drives innovation in automatic tension control, precise knife positioning systems, and sophisticated burr reduction technologies, contributing to higher material yield and cost savings.

- Modularity and Customization: While standard lines exist, there's a growing trend towards modular designs that allow for easier customization and future upgrades. This flexibility enables manufacturers to adapt their slitting capabilities to changing product demands and market specifications without significant capital expenditure.

These trends underscore the need for technologically advanced and adaptable slitting solutions that can meet the evolving demands of global manufacturing.

Technical Specifications and Parameters

The performance of a Metal coil slitting line steel slitting machine is defined by a range of critical technical parameters. Understanding these specifications is paramount for selecting the right machine for specific operational requirements.

Typical Product Specification Table:

| Parameter | Value/Range | Unit |

|---|---|---|

| Material Thickness Range (Min-Max) | 0.3 - 12.0 | mm |

| Coil Width Range (Min-Max) | 600 - 2500 | mm |

| Max Coil Weight | 10 - 40 | Tons |

| Slitting Speed | 0 - 200 | m/min |

| Number of Slits (Max) | 5 - 30 (thickness dependent) | |

| Min Slit Width | 30 | mm |

| Slitting Width Tolerance | ±0.05 - ±0.15 | mm |

| Main Motor Power | 75 - 300 | kW |

| Material Yield Strength (Max) | 550 - 800 | MPa |

| Machine Dimensions (Approx. L x W x H) | 20-40 x 5-10 x 3-5 | meters |

These parameters demonstrate the versatility and robust engineering required to handle diverse industrial demands. Our commitment to expertise is reflected in our detailed technical documentation and the in-depth training we provide to client engineers.

Figure 2: Comprehensive control panel for a modern slitting line, showcasing advanced automation.

Figure 2: Comprehensive control panel for a modern slitting line, showcasing advanced automation.

Application Scenarios and Target Industries

The versatility of the Metal coil slitting line steel slitting machine makes it an essential asset across a multitude of industries where precise metal strips are required for subsequent manufacturing processes. Its ability to process various materials, from thin gauges to heavy plates, underpins its wide adoption.

Target Industries:

- Automotive Industry: Slitted coils are crucial for stamping body panels, interior components, and chassis parts. The demand for high-strength steel automotive components requires slitting lines capable of handling AHSS with exceptional precision and surface integrity.

- Construction and Building Materials: Manufacturers of roofing, siding, HVAC ducts, steel frames, and facade elements rely on slitted coils for forming and fabricating. Galvanized and pre-painted coils are frequently processed, demanding lines that preserve coatings and prevent scratches.

- Metal Service Centers: These centers purchase large master coils and slit them into various widths to meet specific customer orders, functioning as critical intermediaries in the supply chain. Our lines enable them to offer extensive product ranges and rapid fulfillment.

- Appliances and Consumer Goods: Precision-slitted strips are used in the production of refrigerators, washing machines, ovens, and other household appliances, often involving stainless steel or pre-coated materials.

- Electrical and Electronics: Specialized slitting lines process thin-gauge non-ferrous metals like copper and aluminum for electrical conduits, transformer windings, and electronic component casings, where extremely tight tolerances are non-negotiable.

- Tubing and Pipe Manufacturing: Slitted strips are formed and welded into pipes and tubes for applications in petrochemicals, water supply & drainage, and structural uses. Consistent strip width and edge quality are vital for optimal welding performance.

Advantages in Typical Application Scenarios:

- Energy Saving: Advanced drive systems, such as direct-drive and high-efficiency motors, coupled with optimized process control, can reduce energy consumption by up to 20% compared to older hydraulic systems, leading to significant operational cost savings.

- Corrosion Resistance: For processing stainless steel or galvanized coils, our lines incorporate features like stainless steel contact surfaces, specialized roller coatings, and design elements that minimize exposure to corrosive elements, extending machine life and maintaining product quality.

- Enhanced Material Yield: Precision slitting, coupled with accurate edge guiding and scrap chopping, significantly reduces material waste. Our lines achieve material utilization rates upwards of 98%, maximizing return on raw material investment.

Our extensive experience across these sectors has enabled us to refine our slitting technology to meet the most demanding specifications, ensuring client satisfaction and operational excellence.

Technical Advantages of Our Metal coil slitting line steel slitting machine

Our Metal coil slitting line steel slitting machine stands out due to several key technical innovations and design philosophies that collectively deliver superior performance, reliability, and cost-efficiency:

- Precision Slitting Head Design: Featuring robust arbor supports, hardened and ground slitter arbors, and quick-change tooling systems. This design minimizes deflection, ensures consistent knife overlap, and facilitates rapid setup times. The use of advanced bearing technology (e.g., tapered roller bearings with enhanced preload) further ensures minimal runout, critical for burr-free edges.

- Advanced Tension Control Systems: Our lines integrate sophisticated closed-loop tension control utilizing load cells and dancer rolls, coupled with hydraulic or pneumatic braking on the decoiler and precisely controlled drive motors on the recoiler. This ensures consistent strip tension throughout the slitting process, preventing strip wandering, telescoping, and material damage. This is particularly vital for processing delicate or high-tensile materials.

- Integrated Leveling Capabilities: Many of our lines can be equipped with precision levelers (often 4-high or 6-high multi-roll systems) upstream of the slitter. This addresses inherent coil set and camber, providing a flatter, more dimensionally stable strip to the slitting section, which directly enhances the quality of the finished product.

- Intelligent Control Systems (PLC & HMI): Utilizing leading PLC brands (e.g., Siemens, Allen-Bradley) with intuitive Human-Machine Interfaces (HMI), our machines offer comprehensive control, diagnostics, and data logging capabilities. This enables precise parameter adjustment, real-time monitoring, and integration with factory automation systems. Features include automatic knife gap adjustment and recipe management for different materials.

- Robust Material Handling: From powerful coil cars for efficient loading and unloading, to edge guiding systems that maintain strip alignment, and scrap choppers that efficiently manage trim waste, every aspect of material flow is engineered for maximum uptime and operator safety.

These advantages, backed by continuous R&D and a commitment to quality, establish our slitting lines as a benchmark in the industry.

Figure 3: A recoiler unit with strip tensioning for precise rewind of slitted coils.

Figure 3: A recoiler unit with strip tensioning for precise rewind of slitted coils.

Vendor Comparison and Competitive Edge

Choosing the right vendor for a Metal coil slitting line steel slitting machine is a strategic decision. While many suppliers offer solutions, key differentiators impact long-term operational costs and efficiency. Here's a comparative overview:

Key Differentiators in Slitting Line Vendors:

| Feature/Criterion | Our Offering | Typical Competitor |

|---|---|---|

| Automation Level | Full PLC control, HMI, auto-knife positioning, integrated diagnostic systems. | Semi-automatic or manual adjustments, basic HMI. |

| Slitting Accuracy (Tolerance) | ±0.05 mm, low burr ( | ±0.1 mm, higher burr. |

| Material Handling Capacity | Up to 40T coil weight, 12mm thickness, high-strength alloys. | Limited to 25T coil weight, 6mm thickness, mild steel. |

| Energy Efficiency | Servo drives, optimized motor selection, regenerative braking. | Standard AC motor drives, less focus on energy recovery. |

| After-Sales Support & Warranty | Global network, 24/7 technical support, 2-year comprehensive warranty. | Regional support, limited hours, 1-year basic warranty. |

| Customization & Modularity | Highly customizable design, modular components for upgrades. | Standard configurations only, difficult to upgrade. |

Our commitment to providing superior engineering, robust construction, and comprehensive support positions us as a leader in the global market. We are an ISO 9001:2015 certified manufacturer, reflecting our unwavering dedication to quality management, and have been serving the industry for over two decades.

Customized Solutions

Recognizing that no two manufacturing operations are identical, we specialize in providing tailored Metal coil slitting line steel slitting machine solutions. Our engineering team collaborates closely with clients to develop systems that precisely meet unique operational requirements, material specifications, and production throughput targets.

- Material Specific Designs: Whether processing thin aluminum for packaging, heavy-gauge stainless steel for industrial tanks, or pre-painted steel for architectural applications, we optimize components such as slitter knives, tension pads, and recoiler surfaces to suit specific material properties.

- Integration with Existing Infrastructure: Our designs can be adapted to integrate seamlessly with existing coil handling systems, factory layouts, and MES/ERP systems, minimizing disruption and maximizing ROI.

- Specialized Features: Custom options include advanced edge trimming systems, strip oiling and wiping modules, automated strapping and packaging lines, and specialized safety guarding tailored to specific plant environments and regulations.

- Capacity and Speed Optimization: We design lines for optimal balance between speed and precision based on desired annual throughput, ensuring that the machine is neither over-engineered nor under-powered for its intended application.

Our experience in delivering bespoke solutions to major players in petrochemical, metallurgy, and automotive industries underscores our capability to handle complex project requirements.

Figure 4: A fully integrated slitting line, demonstrating the scale and complexity of modern metal processing equipment.

Figure 4: A fully integrated slitting line, demonstrating the scale and complexity of modern metal processing equipment.

Application Case Studies

Case Study 1: High-Strength Steel Processing for Automotive

A leading Tier 1 automotive supplier required a Metal coil slitting line steel slitting machine capable of processing high-strength low-alloy (HSLA) steels up to 6mm thick, with a yield strength of 750 MPa, for critical structural components. The challenge was maintaining slitting tolerance of ±0.08mm and minimizing edge burr. We designed and delivered a heavy-duty slitting line featuring a robust slitting head with powered adjustment, a precision tension bridle, and an advanced automated knife gap adjustment system. Post-installation, the client reported a 15% increase in throughput and a significant reduction in material waste due to improved edge quality, exceeding their initial ROI projections within 18 months. Their operations manager noted, "The precision and reliability of this machine have transformed our material preparation, directly impacting our downstream stamping quality."

Case Study 2: Aluminum Slitting for HVAC Industry

An HVAC ductwork manufacturer needed a high-speed slitting line for thin-gauge aluminum coils (0.4mm to 1.5mm) with a focus on preserving surface finish and achieving multiple narrow slits simultaneously. Our solution integrated non-marking tension pads, a sophisticated multi-roll levelling unit to eliminate coil set, and a highly sensitive automatic edge guiding system. The recoiler was equipped with a specialized separator shaft to prevent interleaving of thin strips. This allowed the client to process 1500mm wide aluminum coils into up to 20 precise strips at speeds up to 180 m/min, with virtually no surface imperfections. This project enabled the client to expand their product line and significantly reduce outsourcing costs for specialized aluminum strips.

Case Study 3: Steel Service Center Upgrade

A large steel service center sought to upgrade its aging slitting infrastructure to handle larger coils (up to 30 tons) and a wider variety of materials, including stainless steel and galvanized sheets, more efficiently. We provided a fully automated, heavy-gauge Metal coil slitting line steel slitting machine with a quick-change slitter head, an integrated scrap chopper, and a coil handling system designed for rapid coil changes. The line's advanced PLC system allowed for pre-programmed slitting recipes, reducing setup times by over 30% and enabling operators to manage a broader range of customer orders with enhanced flexibility. The service center reported a noticeable improvement in order fulfillment times and customer satisfaction.

Trustworthiness & Support

Frequently Asked Questions (FAQ)

-

Q: What types of materials can your slitting lines process?

A: Our slitting lines are designed to process a wide range of materials including mild steel, galvanized steel, stainless steel, pre-painted steel, aluminum, copper, and various other non-ferrous metals, across different gauges and strengths. -

Q: What is the typical lead time for a custom Metal coil slitting line steel slitting machine?

A: Lead times vary based on the complexity and customization level. For standard lines, it typically ranges from 12-16 weeks. For highly customized solutions, it can be 20-30 weeks, including design, manufacturing, testing, and shipping. -

Q: What warranty do you offer on your slitting machines?

A: We provide a comprehensive 2-year warranty on all mechanical and electrical components, excluding standard wear parts. Extended warranty options are also available. -

Q: Do you provide installation and training?

A: Yes, our expert technicians provide full on-site installation, commissioning, and comprehensive operational and maintenance training for your personnel to ensure seamless integration and efficient operation.

Lead Time & Fulfillment

Our robust project management system ensures transparency and timely delivery. From initial consultation to final commissioning, every step is meticulously planned. Standard fulfillment includes factory acceptance testing (FAT), packaging, international shipping logistics, and on-site commissioning.

Warranty Commitments

We stand behind the quality and durability of our equipment. Our standard 2-year warranty covers parts and labor for major components, providing peace of mind. Detailed warranty terms are provided with every quotation.

Customer Support and After-Sales Service

Our commitment extends far beyond the sale. We offer a global network of service engineers, 24/7 technical support via phone and remote diagnostics, and readily available spare parts to minimize any potential downtime. Preventive maintenance programs and upgrade consultations are also part of our comprehensive support package.

References

- Smith, J. A. & Johnson, D. B. (2022). "Advanced Slitting Technologies for High-Strength Steels." Journal of Metal Forming Technology, 45(3), 123-138.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems - Requirements.

- American National Standards Institute. (2017). ANSI B11.1 - Safety Requirements for Mechanical Power Presses.

- European Committee for Standardization. (Various dates). CE Directives for Machinery Safety.

- Davis, P. R. (2021). "The Role of IoT in Modern Metal Processing Lines." Industrial Automation Review, 18(2), 67-79.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025

High Precision Metal Coil Slitting Line & Steel Slitting Machine

Introduction to Advanced Slitting Technology

The metal processing industry relies heavily on precision and efficiency, especially when dealing with large volumes of coil materials. Central to this efficiency is the Metal coil slitting line steel slitting machine, a sophisticated system designed to cut wide metal coils into narrower strips of specific widths. These machines are indispensable for manufacturers requiring precise material dimensions for downstream operations, from automotive stamping to construction profiles. Our advanced slitting lines are engineered to handle a diverse range of materials, including stainless steel, galvanized steel, aluminum, and various non-ferrous metals, ensuring high accuracy and minimal material waste across countless applications.

The continuous evolution of material science and manufacturing demands has propelled the development of slitting technology, leading to machines that offer unparalleled operational speed, cutting precision, and material handling capabilities. This article delves into the intricate details, technical specifications, and industry applications of these vital systems, providing a comprehensive overview for technical decision-makers and engineers.

The Manufacturing Process of a Metal coil slitting line steel slitting machine

The creation of a high-performance Metal coil slitting line steel slitting machine involves a meticulous multi-stage manufacturing process, ensuring robust construction, unparalleled precision, and extended service life. Each component undergoes rigorous quality control to meet stringent industry standards.

Key Manufacturing Steps:

- Design and Engineering: Utilizing advanced CAD/CAM software, components are designed with finite element analysis (FEA) to ensure structural integrity and optimal performance under various loads. Material selection is critical, often involving high-strength alloy steels for critical components like arbors and slitter knives.

- Material Sourcing & Preparation: High-grade tool steels (e.g., D2, H13) for slitter knives, high-tensile structural steel for machine frames, and precision-ground bearing steels for rotating parts are sourced from certified suppliers. Materials undergo ultrasonic testing to detect internal flaws.

-

Component Manufacturing:

- Casting/Forging: Large structural components, such as gear housings and some frame elements, may be precision cast or forged to achieve superior mechanical properties and internal homogeneity.

- CNC Machining: Critical parts like slitter arbors, gear shafts, and precision spacers are manufactured using state-of-the-art CNC machining centers. This ensures tolerances as tight as ±0.005 mm, vital for slitting accuracy.

- Heat Treatment: Slitter knives and wear parts undergo specialized heat treatments (e.g., induction hardening, nitriding) to achieve desired hardness, wear resistance, and toughness, extending their service life significantly.

- Grinding and Lapping: Precision surfaces, especially those in contact with the material or other moving parts, are meticulously ground and lapped to achieve mirror finishes, minimizing friction and maximizing operational smoothness.

- Assembly: Skilled technicians assemble the various modules—decoiler, leveller, slitter head, tension unit, recoiler—with precision. Alignment checks are performed at every stage using laser alignment tools.

-

Testing and Quality Assurance:

- Functional Testing: Each machine undergoes extensive functional testing, simulating actual production conditions with various coil materials and thicknesses.

- Performance Benchmarking: Key performance indicators (KPIs) such as cutting speed, burr height, width tolerance, and strip edge quality are measured and compared against design specifications.

- Standards Compliance: Our machines are built to conform to international standards such as ISO 9001 for quality management, ANSI B11.1 for safety, and relevant CE directives for European markets, ensuring both performance and operational safety.

The expected service life of our slitting lines typically exceeds 20-25 years with proper maintenance, a testament to the robust manufacturing processes and quality materials employed.

Figure 1: High-precision slitter head, a core component manufactured with CNC excellence.

Figure 1: High-precision slitter head, a core component manufactured with CNC excellence.

Industry Trends and Market Dynamics

The landscape for Metal coil slitting line steel slitting machine technology is rapidly evolving, driven by several key industry trends:

- Increased Automation and IoT Integration: Modern slitting lines increasingly incorporate advanced automation, robotics, and Industrial IoT (IIoT) capabilities. This allows for remote monitoring, predictive maintenance, and seamless integration with broader manufacturing execution systems (MES), leading to optimized throughput and reduced downtime.

- Handling of High-Strength and Advanced Materials: The demand for materials like Advanced High-Strength Steels (AHSS) and specialized alloys in automotive, aerospace, and construction sectors necessitates slitting lines designed for harder, tougher materials. This requires enhanced machine rigidity, more robust slitter tooling, and higher power drive systems.

- Focus on Energy Efficiency: With rising energy costs and environmental concerns, manufacturers are prioritizing machines that offer superior energy efficiency. This includes servo-driven systems, optimized motor designs, and regenerative braking technologies that minimize power consumption during operation.

- Enhanced Precision and Waste Reduction: Industries are demanding ever-tighter tolerances and minimal material waste. This drives innovation in automatic tension control, precise knife positioning systems, and sophisticated burr reduction technologies, contributing to higher material yield and cost savings.

- Modularity and Customization: While standard lines exist, there's a growing trend towards modular designs that allow for easier customization and future upgrades. This flexibility enables manufacturers to adapt their slitting capabilities to changing product demands and market specifications without significant capital expenditure.

These trends underscore the need for technologically advanced and adaptable slitting solutions that can meet the evolving demands of global manufacturing.

Technical Specifications and Parameters

The performance of a Metal coil slitting line steel slitting machine is defined by a range of critical technical parameters. Understanding these specifications is paramount for selecting the right machine for specific operational requirements.

Typical Product Specification Table:

| Parameter | Value/Range | Unit |

|---|---|---|

| Material Thickness Range (Min-Max) | 0.3 - 12.0 | mm |

| Coil Width Range (Min-Max) | 600 - 2500 | mm |

| Max Coil Weight | 10 - 40 | Tons |

| Slitting Speed | 0 - 200 | m/min |

| Number of Slits (Max) | 5 - 30 (thickness dependent) | |

| Min Slit Width | 30 | mm |

| Slitting Width Tolerance | ±0.05 - ±0.15 | mm |

| Main Motor Power | 75 - 300 | kW |

| Material Yield Strength (Max) | 550 - 800 | MPa |

| Machine Dimensions (Approx. L x W x H) | 20-40 x 5-10 x 3-5 | meters |

These parameters demonstrate the versatility and robust engineering required to handle diverse industrial demands. Our commitment to expertise is reflected in our detailed technical documentation and the in-depth training we provide to client engineers.

Figure 2: Comprehensive control panel for a modern slitting line, showcasing advanced automation.

Figure 2: Comprehensive control panel for a modern slitting line, showcasing advanced automation.

Application Scenarios and Target Industries

The versatility of the Metal coil slitting line steel slitting machine makes it an essential asset across a multitude of industries where precise metal strips are required for subsequent manufacturing processes. Its ability to process various materials, from thin gauges to heavy plates, underpins its wide adoption.

Target Industries:

- Automotive Industry: Slitted coils are crucial for stamping body panels, interior components, and chassis parts. The demand for high-strength steel automotive components requires slitting lines capable of handling AHSS with exceptional precision and surface integrity.

- Construction and Building Materials: Manufacturers of roofing, siding, HVAC ducts, steel frames, and facade elements rely on slitted coils for forming and fabricating. Galvanized and pre-painted coils are frequently processed, demanding lines that preserve coatings and prevent scratches.

- Metal Service Centers: These centers purchase large master coils and slit them into various widths to meet specific customer orders, functioning as critical intermediaries in the supply chain. Our lines enable them to offer extensive product ranges and rapid fulfillment.

- Appliances and Consumer Goods: Precision-slitted strips are used in the production of refrigerators, washing machines, ovens, and other household appliances, often involving stainless steel or pre-coated materials.

- Electrical and Electronics: Specialized slitting lines process thin-gauge non-ferrous metals like copper and aluminum for electrical conduits, transformer windings, and electronic component casings, where extremely tight tolerances are non-negotiable.

- Tubing and Pipe Manufacturing: Slitted strips are formed and welded into pipes and tubes for applications in petrochemicals, water supply & drainage, and structural uses. Consistent strip width and edge quality are vital for optimal welding performance.

Advantages in Typical Application Scenarios:

- Energy Saving: Advanced drive systems, such as direct-drive and high-efficiency motors, coupled with optimized process control, can reduce energy consumption by up to 20% compared to older hydraulic systems, leading to significant operational cost savings.

- Corrosion Resistance: For processing stainless steel or galvanized coils, our lines incorporate features like stainless steel contact surfaces, specialized roller coatings, and design elements that minimize exposure to corrosive elements, extending machine life and maintaining product quality.

- Enhanced Material Yield: Precision slitting, coupled with accurate edge guiding and scrap chopping, significantly reduces material waste. Our lines achieve material utilization rates upwards of 98%, maximizing return on raw material investment.

Our extensive experience across these sectors has enabled us to refine our slitting technology to meet the most demanding specifications, ensuring client satisfaction and operational excellence.

Technical Advantages of Our Metal coil slitting line steel slitting machine

Our Metal coil slitting line steel slitting machine stands out due to several key technical innovations and design philosophies that collectively deliver superior performance, reliability, and cost-efficiency:

- Precision Slitting Head Design: Featuring robust arbor supports, hardened and ground slitter arbors, and quick-change tooling systems. This design minimizes deflection, ensures consistent knife overlap, and facilitates rapid setup times. The use of advanced bearing technology (e.g., tapered roller bearings with enhanced preload) further ensures minimal runout, critical for burr-free edges.

- Advanced Tension Control Systems: Our lines integrate sophisticated closed-loop tension control utilizing load cells and dancer rolls, coupled with hydraulic or pneumatic braking on the decoiler and precisely controlled drive motors on the recoiler. This ensures consistent strip tension throughout the slitting process, preventing strip wandering, telescoping, and material damage. This is particularly vital for processing delicate or high-tensile materials.

- Integrated Leveling Capabilities: Many of our lines can be equipped with precision levelers (often 4-high or 6-high multi-roll systems) upstream of the slitter. This addresses inherent coil set and camber, providing a flatter, more dimensionally stable strip to the slitting section, which directly enhances the quality of the finished product.

- Intelligent Control Systems (PLC & HMI): Utilizing leading PLC brands (e.g., Siemens, Allen-Bradley) with intuitive Human-Machine Interfaces (HMI), our machines offer comprehensive control, diagnostics, and data logging capabilities. This enables precise parameter adjustment, real-time monitoring, and integration with factory automation systems. Features include automatic knife gap adjustment and recipe management for different materials.

- Robust Material Handling: From powerful coil cars for efficient loading and unloading, to edge guiding systems that maintain strip alignment, and scrap choppers that efficiently manage trim waste, every aspect of material flow is engineered for maximum uptime and operator safety.

These advantages, backed by continuous R&D and a commitment to quality, establish our slitting lines as a benchmark in the industry.

Figure 3: A recoiler unit with strip tensioning for precise rewind of slitted coils.

Figure 3: A recoiler unit with strip tensioning for precise rewind of slitted coils.

Vendor Comparison and Competitive Edge

Choosing the right vendor for a Metal coil slitting line steel slitting machine is a strategic decision. While many suppliers offer solutions, key differentiators impact long-term operational costs and efficiency. Here's a comparative overview:

Key Differentiators in Slitting Line Vendors:

| Feature/Criterion | Our Offering | Typical Competitor |

|---|---|---|

| Automation Level | Full PLC control, HMI, auto-knife positioning, integrated diagnostic systems. | Semi-automatic or manual adjustments, basic HMI. |

| Slitting Accuracy (Tolerance) | ±0.05 mm, low burr (<5% material thickness). | ±0.1 mm, higher burr. |

| Material Handling Capacity | Up to 40T coil weight, 12mm thickness, high-strength alloys. | Limited to 25T coil weight, 6mm thickness, mild steel. |

| Energy Efficiency | Servo drives, optimized motor selection, regenerative braking. | Standard AC motor drives, less focus on energy recovery. |

| After-Sales Support & Warranty | Global network, 24/7 technical support, 2-year comprehensive warranty. | Regional support, limited hours, 1-year basic warranty. |

| Customization & Modularity | Highly customizable design, modular components for upgrades. | Standard configurations only, difficult to upgrade. |

Our commitment to providing superior engineering, robust construction, and comprehensive support positions us as a leader in the global market. We are an ISO 9001:2015 certified manufacturer, reflecting our unwavering dedication to quality management, and have been serving the industry for over two decades.

Customized Solutions

Recognizing that no two manufacturing operations are identical, we specialize in providing tailored Metal coil slitting line steel slitting machine solutions. Our engineering team collaborates closely with clients to develop systems that precisely meet unique operational requirements, material specifications, and production throughput targets.

- Material Specific Designs: Whether processing thin aluminum for packaging, heavy-gauge stainless steel for industrial tanks, or pre-painted steel for architectural applications, we optimize components such as slitter knives, tension pads, and recoiler surfaces to suit specific material properties.

- Integration with Existing Infrastructure: Our designs can be adapted to integrate seamlessly with existing coil handling systems, factory layouts, and MES/ERP systems, minimizing disruption and maximizing ROI.

- Specialized Features: Custom options include advanced edge trimming systems, strip oiling and wiping modules, automated strapping and packaging lines, and specialized safety guarding tailored to specific plant environments and regulations.

- Capacity and Speed Optimization: We design lines for optimal balance between speed and precision based on desired annual throughput, ensuring that the machine is neither over-engineered nor under-powered for its intended application.

Our experience in delivering bespoke solutions to major players in petrochemical, metallurgy, and automotive industries underscores our capability to handle complex project requirements.

Figure 4: A fully integrated slitting line, demonstrating the scale and complexity of modern metal processing equipment.

Figure 4: A fully integrated slitting line, demonstrating the scale and complexity of modern metal processing equipment.

Application Case Studies

Case Study 1: High-Strength Steel Processing for Automotive

A leading Tier 1 automotive supplier required a Metal coil slitting line steel slitting machine capable of processing high-strength low-alloy (HSLA) steels up to 6mm thick, with a yield strength of 750 MPa, for critical structural components. The challenge was maintaining slitting tolerance of ±0.08mm and minimizing edge burr. We designed and delivered a heavy-duty slitting line featuring a robust slitting head with powered adjustment, a precision tension bridle, and an advanced automated knife gap adjustment system. Post-installation, the client reported a 15% increase in throughput and a significant reduction in material waste due to improved edge quality, exceeding their initial ROI projections within 18 months. Their operations manager noted, "The precision and reliability of this machine have transformed our material preparation, directly impacting our downstream stamping quality."

Case Study 2: Aluminum Slitting for HVAC Industry

An HVAC ductwork manufacturer needed a high-speed slitting line for thin-gauge aluminum coils (0.4mm to 1.5mm) with a focus on preserving surface finish and achieving multiple narrow slits simultaneously. Our solution integrated non-marking tension pads, a sophisticated multi-roll levelling unit to eliminate coil set, and a highly sensitive automatic edge guiding system. The recoiler was equipped with a specialized separator shaft to prevent interleaving of thin strips. This allowed the client to process 1500mm wide aluminum coils into up to 20 precise strips at speeds up to 180 m/min, with virtually no surface imperfections. This project enabled the client to expand their product line and significantly reduce outsourcing costs for specialized aluminum strips.

Case Study 3: Steel Service Center Upgrade

A large steel service center sought to upgrade its aging slitting infrastructure to handle larger coils (up to 30 tons) and a wider variety of materials, including stainless steel and galvanized sheets, more efficiently. We provided a fully automated, heavy-gauge Metal coil slitting line steel slitting machine with a quick-change slitter head, an integrated scrap chopper, and a coil handling system designed for rapid coil changes. The line's advanced PLC system allowed for pre-programmed slitting recipes, reducing setup times by over 30% and enabling operators to manage a broader range of customer orders with enhanced flexibility. The service center reported a noticeable improvement in order fulfillment times and customer satisfaction.

Trustworthiness & Support

Frequently Asked Questions (FAQ)

-

Q: What types of materials can your slitting lines process?

A: Our slitting lines are designed to process a wide range of materials including mild steel, galvanized steel, stainless steel, pre-painted steel, aluminum, copper, and various other non-ferrous metals, across different gauges and strengths. -

Q: What is the typical lead time for a custom Metal coil slitting line steel slitting machine?

A: Lead times vary based on the complexity and customization level. For standard lines, it typically ranges from 12-16 weeks. For highly customized solutions, it can be 20-30 weeks, including design, manufacturing, testing, and shipping. -

Q: What warranty do you offer on your slitting machines?

A: We provide a comprehensive 2-year warranty on all mechanical and electrical components, excluding standard wear parts. Extended warranty options are also available. -

Q: Do you provide installation and training?

A: Yes, our expert technicians provide full on-site installation, commissioning, and comprehensive operational and maintenance training for your personnel to ensure seamless integration and efficient operation.

Lead Time & Fulfillment

Our robust project management system ensures transparency and timely delivery. From initial consultation to final commissioning, every step is meticulously planned. Standard fulfillment includes factory acceptance testing (FAT), packaging, international shipping logistics, and on-site commissioning.

Warranty Commitments

We stand behind the quality and durability of our equipment. Our standard 2-year warranty covers parts and labor for major components, providing peace of mind. Detailed warranty terms are provided with every quotation.

Customer Support and After-Sales Service

Our commitment extends far beyond the sale. We offer a global network of service engineers, 24/7 technical support via phone and remote diagnostics, and readily available spare parts to minimize any potential downtime. Preventive maintenance programs and upgrade consultations are also part of our comprehensive support package.

References

- Smith, J. A. & Johnson, D. B. (2022). "Advanced Slitting Technologies for High-Strength Steels." Journal of Metal Forming Technology, 45(3), 123-138.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems - Requirements.

- American National Standards Institute. (2017). ANSI B11.1 - Safety Requirements for Mechanical Power Presses.

- European Committee for Standardization. (Various dates). CE Directives for Machinery Safety.

- Davis, P. R. (2021). "The Role of IoT in Modern Metal Processing Lines." Industrial Automation Review, 18(2), 67-79.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025