Custom Metal Steel Plate Embossing Machine | High Precision

Introduction to Advanced Metal Plate Embossing Technology

In industrial manufacturing, the demand for precision, aesthetics, and functional enhancement of metal surfaces continues to grow. This growth is particularly evident in sectors requiring anti-slip surfaces, decorative elements, or structural reinforcement in thin gauge materials. The Metal Steel Plate Embossing Machine stands as a critical innovation, transforming flat metal sheets into textured components with unparalleled efficiency and accuracy. This article delves into the operational intricacies, technical merits, and diverse applications of these advanced machines, providing B2B decision-makers with a comprehensive understanding of their value proposition.

The global market for metal forming machinery, including embossing equipment, is projected to reach significant valuation, driven by advancements in automation and the increasing use of sheet metal across various industries. According to market research, the global metal fabrication equipment market is expected to grow at a CAGR of over 4% from 2023 to 2028, with embossing and pressing technologies playing a vital role in this expansion due to their ability to add value and functionality to raw materials.

The Manufacturing Process Flow of a Metal Steel Plate Embossing Machine

The production of a robust and reliable Metal Steel Plate Embossing Machine involves a meticulously controlled multi-stage manufacturing process, ensuring precision, durability, and optimal performance. Our commitment to ISO 9001 certified manufacturing practices underpins every stage.

Key Process Steps:

- Material Selection and Preparation: High-grade structural steel (e.g., Q235, Q345, S355JR for main frame components) and alloy steel (e.g., 42CrMo for rolls/dies) are chosen based on their yield strength, tensile strength, and wear resistance. Hydraulic components utilize precision-machined stainless steel or treated carbon steel to prevent corrosion and ensure pressure integrity.

- Frame Fabrication (Welding & Stress Relieving): The machine's core structure, often a robust C-frame or four-column design, is fabricated through advanced welding techniques (MIG/MAG) to ensure structural rigidity. Post-welding, components undergo heat treatment or vibration aging to relieve internal stresses, preventing deformation during operation and extending service life.

- Precision Component Machining (CNC): Critical parts such as embossing rollers, hydraulic cylinders, and guide posts are machined using state-of-the-art CNC machining centers. This ensures tight tolerances (e.g., ±0.01mm) crucial for consistent embossing patterns and smooth mechanical operation. Rollers often undergo precision grinding and surface hardening (e.g., induction hardening to HRC55-60) for enhanced wear resistance.

- Hydraulic System Integration: High-efficiency hydraulic power units, including pumps, valves, and cylinders from reputable brands, are integrated. Piping is meticulously installed and tested for leaks, and pressure systems are calibrated to ensure accurate tonnage control and rapid response.

- Electrical & Control System Assembly: PLC-based control systems, touch-screen HMIs (Human-Machine Interfaces), and servo-driven motors for precise sheet feeding are integrated. Wiring adheres to IEC standards, and safety features like emergency stops, light curtains, and overload protection are implemented according to CE and ANSI B11.1 standards.

- Assembly and Alignment: All sub-assemblies are brought together, with critical alignment procedures performed using laser alignment tools to ensure parallel rollers and precise die registration.

- Testing and Quality Assurance: Every machine undergoes rigorous testing, including no-load operation, full-load embossing tests with various materials (e.g., carbon steel, stainless steel, aluminum), and endurance tests. Critical parameters like embossing depth consistency, pressure stability, and noise levels are measured against strict internal and international standards (e.g., ISO 8528 for noise, ASTM E8/E9 for material deformation). Service life for major components is typically designed for 10-15 years under normal operating conditions.

- Surface Treatment and Finishing: Components are cleaned, primed, and coated with industrial-grade paint for corrosion resistance and aesthetic appeal.

Target industries for our robust embossing machines include petrochemical (anti-slip platforms), metallurgy (decorative panels, textured sheets), and water supply & drainage (grating, manhole covers). Our machines demonstrate advantages in typical application scenarios such as energy saving through optimized hydraulic systems and superior corrosion resistance due to material selection and surface treatments, leading to extended operational life and reduced maintenance.

Technical Specifications and Parameters

Our range of Metal Steel Plate Embossing Machine models is engineered to meet diverse industrial requirements, offering a blend of power, precision, and efficiency. The following table outlines typical technical parameters for a high-performance model, illustrating the capabilities crucial for B2B operations.

Typical Product Specifications:

| Parameter | Specification | Notes |

|---|---|---|

| Max. Embossing Width | 1500 mm (customizable up to 2000 mm) | Accommodates various sheet sizes. |

| Max. Material Thickness | 0.5 mm - 6.0 mm (Mild Steel) | Capacity varies with material type and pattern depth. |

| Embossing Tonnage | 200 Ton - 800 Ton (Hydraulic) | Adjustable hydraulic pressure for different patterns and materials. |

| Embossing Speed | Up to 10-15 m/min | Optimized for throughput and pattern quality. |

| Roller Material | 42CrMo Alloy Steel (Heat Treated & Hardened) | Ensures long lifespan and resistance to wear. |

| Control System | PLC Control with HMI Touchscreen (Siemens/Schneider) | Intuitive operation, diagnostic capabilities, pattern storage. |

| Motor Power | 30 kW - 75 kW (depending on model) | Energy-efficient design. |

| Dimensions (L x W x H) | Approx. 4500 x 2000 x 2500 mm | Compact footprint for industrial environments. |

| Weight | 15,000 kg - 35,000 kg | Indicates robust construction. |

| Safety Standards | CE, ISO, ANSI B11.1 compliant | Ensures operator safety and regulatory compliance. |

Key Technical Advantages

Our advanced Metal Steel Plate Embossing Machine offers a multitude of technical advantages that directly translate into operational efficiency, cost savings, and superior product quality for our clients. These machines are engineered for demanding industrial environments.

- Precision & Repeatability: Equipped with high-resolution encoders and servo-driven feeding systems, our machines achieve embossing patterns with exceptional accuracy and consistent depth across entire batches, critical for architectural panels or automotive components.

- Robust Hydraulic System: Utilizing advanced proportional valve technology, our hydraulic presses offer fine control over tonnage, allowing for precise pressure adjustments to accommodate various material types (e.g., stainless steel, aluminum, carbon steel) and thicknesses without compromising die life or pattern integrity.

- Enhanced Die & Roller Durability: Embossing rollers and dies are manufactured from high-grade alloy steels (e.g., Cr12MoV, 42CrMo), meticulously heat-treated, and surface-hardened to achieve superior hardness (HRC 58-62) and wear resistance. This significantly extends tool life, reducing maintenance costs and downtime.

- Advanced Automation & Control: Integration of Siemens or Schneider PLCs with intuitive HMI touchscreens simplifies operation, allows for programmable pattern sequences, real-time diagnostics, and remote monitoring capabilities. This reduces reliance on highly specialized operators and enhances overall productivity.

- Energy Efficiency: Modern hydraulic systems incorporate variable frequency drives (VFDs) and energy-saving pump technologies, optimizing power consumption based on load requirements. This leads to substantial energy cost reductions compared to traditional fixed-speed systems.

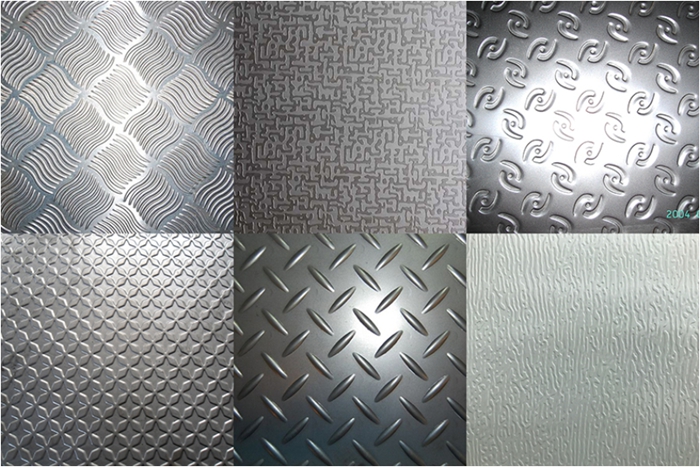

- Versatility & Customization: Our machines are designed with modularity, allowing for rapid die changeovers and accommodating a wide range of embossing patterns—from intricate decorative designs to functional anti-slip textures. Custom dies can be rapidly fabricated to client specifications.

- Integrated Safety Features: Compliance with international safety standards (e.g., CE, OSHA) is paramount. Features include light curtains, emergency stop buttons, hydraulic overload protection, and interlocked guards, ensuring a safe working environment for operators.

Application Scenarios

The versatility of the Metal Steel Plate Embossing Machine makes it indispensable across a broad spectrum of industries. Its ability to impart texture, strength, and aesthetic appeal to metal sheets opens up numerous application possibilities.

Typical Application Areas:

- Automotive Industry: Embossed metal sheets are extensively used for anti-slip floor panels in commercial vehicles, bus interiors, and truck beds. They also find application in decorative trim, reducing material weight while maintaining rigidity.

- Construction & Architecture: Embossed steel plates are crucial for non-slip stair treads, ramps, and walkways in industrial facilities and public spaces. Architecturally, textured metal facades, ceiling panels, and decorative screens leverage embossing for unique aesthetic effects and improved rigidity.

- Home Appliances & HVAC: Embossed patterns on refrigerator doors, washing machine panels, and HVAC ducting can enhance aesthetic appeal, improve structural rigidity, and even optimize heat transfer properties.

- Shipbuilding & Marine: Anti-slip deck plates, engine room flooring, and gangways on ships and offshore platforms benefit significantly from embossed patterns, enhancing safety in wet conditions. The corrosion resistance of chosen materials is vital here.

- Industrial Machinery & Equipment: Control panels, protective covers, and machine enclosures often feature embossed designs for structural integrity, aesthetic improvement, and resistance to scratches or dents.

- Storage Solutions: Textured surfaces on shelves, cabinets, and storage lockers provide enhanced grip, durability, and a professional appearance.

- Decorative Applications: From interior design elements to outdoor signage, embossed metals offer a sophisticated and durable finish, resisting environmental wear and tear.

Customized Solutions and Vendor Comparison

Recognizing that standard solutions may not always suffice, we specialize in providing customized Metal Steel Plate Embossing Machine solutions tailored to unique operational demands. This includes bespoke pattern development, variable width and thickness capabilities, and integration with existing production lines.

Customization Options:

- Pattern Design & Die Fabrication: From specific anti-slip textures (e.g., diamond plate, checker plate) to intricate aesthetic patterns, our engineering team works with clients to design and fabricate custom embossing dies, often utilizing advanced CNC milling and EDM processes.

- Machine Dimensions & Tonnage: Machines can be custom-built to handle exceptionally wide or thick materials, or for higher tonnage requirements for deeper, more complex embossing.

- Automation Level: Integration of coil decoilers, straighteners, cut-to-length lines, stackers, and robotic handling systems can be customized to achieve full automation, minimizing manual intervention and maximizing throughput.

- Material Compatibility: Specialized roller materials and coatings can be selected for processing exotic alloys or extremely soft materials without damaging surfaces.

Vendor Comparison: Why Choose Us

When evaluating suppliers for a metal embossing machine, discerning buyers look beyond initial cost to total cost of ownership (TCO), reliability, and after-sales support. Below is a comparison with typical market offerings.

| Feature | Our Machine (LW Roll Forming) | Competitor A (Mid-tier) | Competitor B (Budget) |

|---|---|---|---|

| Roller/Die Material & Hardness | 42CrMo/Cr12MoV, HRC 58-62 (induction hardened) | GCr15, HRC 50-55 (quenched) | Standard Carbon Steel, HRC 45-50 |

| Hydraulic System Brand | Bosch Rexroth / Parker (Proportional Valve Control) | Local Brand (Fixed Valve Control) | Generic Components |

| Control System | Siemens S7-1200 PLC + KTP HMI | Delta/Mitsubishi PLC + Basic HMI | Relay Logic / Basic PLC |

| Embossing Depth Consistency | ±0.02 mm (High Precision) | ±0.05 mm (Moderate) | ±0.1 mm (Basic) |

| Energy Efficiency | High (VFDs, optimized pump cycle) | Medium (Standard pump) | Low (Constant speed motor) |

| After-Sales Support | Global, 24/7 Remote & On-site | Regional, limited on-site | Basic, often third-party |

| Certifications | ISO 9001, CE, TUV verified | CE certified | No specific certifications |

Real-world Case Studies & Customer Experience

Our decade-long experience in supplying advanced metal forming solutions is underlined by successful deployments and positive customer feedback. We have partnered with leading manufacturers across various sectors, demonstrating our commitment to quality and performance.

Case Study 1: Automotive Component Manufacturer

A major automotive Tier-1 supplier required a solution to produce lightweight, anti-slip floor panels for electric vehicle chassis. They needed high throughput and consistent pattern depth on aluminum alloy sheets up to 3mm thick. Our customized Metal Steel Plate Embossing Machine, integrated with an automatic coil feeding and shearing line, delivered an impressive production rate increase of 30% and maintained pattern uniformity within ±0.03mm, exceeding their initial specifications. Customer feedback highlighted the machine's robust build quality and the intuitive HMI, which simplified pattern changeovers.

Case Study 2: Architectural Metal Fabricator

An architectural firm sought to create bespoke textured stainless steel facades for a high-profile commercial building project. The challenge was to achieve complex, deep patterns on large format stainless steel sheets while minimizing material stress and distortion. Our high-tonnage embossing machine, featuring precision-ground rollers and a dynamic pressure control system, successfully produced the intricate patterns. The client lauded the machine's ability to handle delicate materials without creasing and the exceptional finish quality, which met the stringent aesthetic demands of their project. The project was delivered ahead of schedule due to the machine's efficiency.

Customer Testimonial:

"We've been operating our LW Roll Forming embossing machine for over five years, and it consistently delivers. The precision and durability of the rollers are outstanding, even with our heavy production schedule. Their technical support has also been incredibly responsive, ensuring minimal downtime." - Operations Manager, Industrial Flooring Solutions Inc.

Ensuring Trust: Certifications, Warranty & Support

Building long-term partnerships in the B2B sector requires unwavering trust, backed by verifiable credentials and robust support systems. We are committed to transparency and reliability in every aspect of our operations.

Authoritative Credentials:

- ISO 9001:2015 Certified: Our manufacturing facility adheres to international standards for quality management systems, ensuring consistent product quality and continuous improvement.

- CE Compliant: All our machines are designed and manufactured to meet the strict safety, health, and environmental protection requirements of the European Union.

- Strategic Partnerships: We leverage components from global leaders such as Siemens, Schneider Electric, Bosch Rexroth, and Parker, ensuring reliability and global serviceability of critical parts.

- Decades of Experience: With over 15 years in the metal forming machinery industry, our accumulated expertise translates into superior product design and performance.

Warranty Commitments:

We provide a comprehensive 12-month warranty on all mechanical and electrical components, effective from the date of installation or 15 months from shipment, whichever comes first. This warranty covers defects in material and workmanship under normal operating conditions. Extended warranty options are available upon request.

After-Sales Support & Service:

- 24/7 Technical Assistance: Our dedicated support team is available around the clock via phone and email to provide troubleshooting and operational guidance.

- Remote Diagnostics: Machines equipped with advanced control systems allow for remote access for diagnostics and software updates, minimizing the need for on-site visits.

- On-site Installation & Training: Our experienced engineers provide professional installation, commissioning, and comprehensive operator training at your facility.

- Spare Parts Availability: We maintain a substantial inventory of genuine spare parts to ensure rapid dispatch and minimize downtime.

Frequently Asked Questions (FAQ)

Q1: What materials can the Metal Steel Plate Embossing Machine process?

Our machines are highly versatile and can emboss a wide range of metal sheets, including carbon steel, stainless steel, galvanized steel, aluminum, copper, and brass. The maximum thickness and specific pattern capabilities vary depending on the machine model and material properties.

Q2: How complex can the embossing patterns be?

We can accommodate a vast array of patterns, from standard checker plates and diamond patterns to highly intricate decorative designs and custom logos. Our engineering team works closely with clients to develop and fabricate custom dies to meet specific design requirements.

Q3: What is the typical lead time for an embossing machine?

Standard models typically have a lead time of 8-12 weeks from order confirmation to shipment. Custom-engineered machines, depending on their complexity and customization level, may require 12-20 weeks. We will provide a precise lead time estimate during the quotation phase.

Q4: Is installation and training included?

Yes, we offer comprehensive on-site installation, commissioning, and operator training services by our qualified technicians. This ensures your team is proficient in operating and maintaining the machine safely and efficiently.

Q5: What are the power requirements for these machines?

Our machines typically require a three-phase power supply (e.g., 380V/50Hz, 415V/50Hz, 480V/60Hz) depending on the regional standard and machine configuration. Specific power consumption details are provided in the technical specifications for each model.

Lead Time and Fulfillment

Understanding the importance of project timelines, we streamline our production and logistics to ensure efficient fulfillment. Our standard lead time for most models of Metal Steel Plate Embossing Machine is between 8 to 12 weeks from the receipt of the confirmed order and initial payment. For highly customized configurations or large-scale integrated lines, lead times may extend to 12 to 20 weeks, depending on the complexity of engineering and component sourcing.

Our fulfillment process includes rigorous final testing, professional packaging for international transit (ISPM 15 compliant wooden crates), and coordination with trusted global shipping partners. We provide full documentation, including operation manuals, electrical diagrams, and spare parts lists, to facilitate smooth customs clearance and installation at your facility.

Citations

- Manufacturing Technology Research. "Global Metal Fabrication Equipment Market Outlook 2023-2028." Published by Industry Trends Analysis.

- ASM Handbook, Volume 14B: Metalworking: Sheet Forming. "Fundamentals of Embossing and Roll Forming Processes." ASM International, 2018.

- International Journal of Advanced Manufacturing Technology. "Optimization of Hydraulic Press Parameters for Deep Drawing and Embossing Operations." Springer, 2021.

- Journal of Materials Processing Technology. "Surface Hardening Techniques for High-Wear Components in Forming Machinery." Elsevier, 2020.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025