z shape purlin roll forming machine

Understanding Z Shape Purlin Roll Forming Machines

In the construction and manufacturing industries, efficiency and precision are crucial, especially when it comes to structural components. Purlins are essential elements in building frameworks, serving as horizontal support beams for roofing and siding. Among the various types of purlins, Z shape purlins are widely used due to their unique design that offers superior strength and flexibility. The production of these purlins is primarily facilitated by Z shape purlin roll forming machines, which are designed to produce high-quality purlins in a cost-effective manner.

What is a Z Shape Purlin?

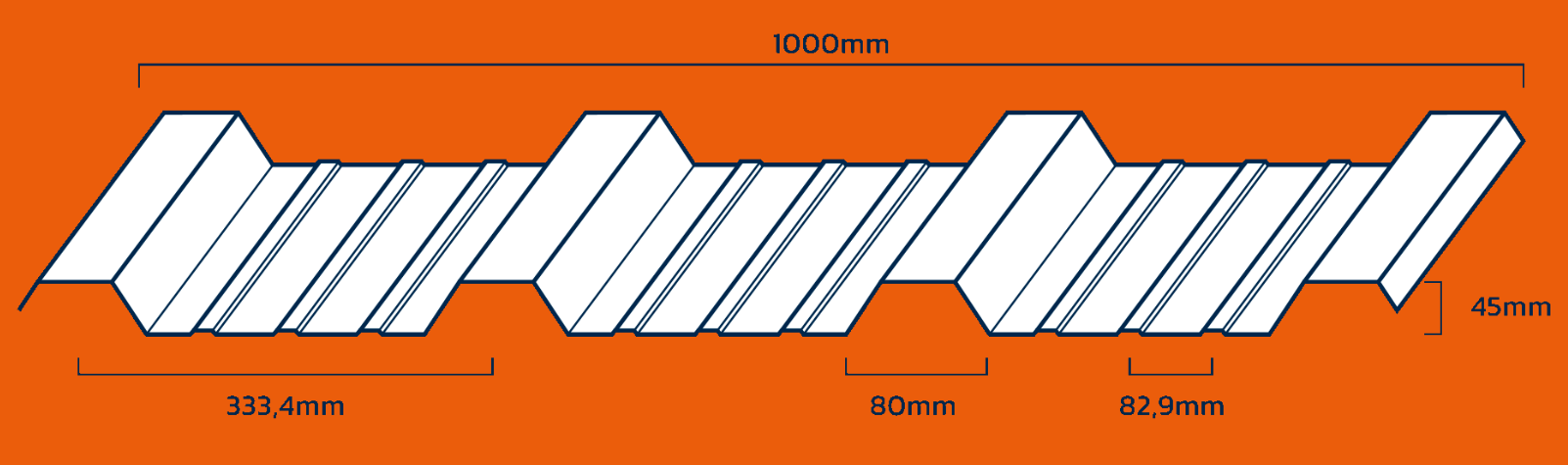

Z shape purlins are typically made from galvanized steel or other durable materials. Their distinctive shape resembles the letter Z, where the flanges of the purlin are oriented in opposite directions. This design not only helps in distributing loads evenly but also allows for easy interconnection with other structural elements, improving the structural integrity of the building. The efficiency of Z shape purlins makes them ideal for use in a variety of applications, including warehouses, workshops, and agricultural buildings.

The Role of Roll Forming Machines

Roll forming machines are specialized equipment that processes metal strips into desired shapes by passing them through a series of rollers. In the case of Z shape purlins, the roll forming process involves several steps, starting with feeding a flat metal sheet into the machine. As the metal sheet moves through the set of rollers, it is gradually shaped into the Z profile, ensuring precise dimensions and consistency throughout the production process.

One of the key advantages of using a Z shape purlin roll forming machine is the ability to customize the specifications according to project requirements. Manufacturers can adjust the machine settings to produce purlins of varying lengths, thicknesses, and widths, thereby accommodating different structural needs. This customization capability also allows for the efficient use of materials, minimizing waste and lowering production costs.

Benefits of Z Shape Purlin Roll Forming Machines

z shape purlin roll forming machine

1. High Efficiency Z shape purlin roll forming machines are designed for high-speed production, significantly reducing manufacturing time. This efficiency is crucial in meeting project deadlines, especially in the fast-paced construction industry.

2. Cost-Effective Production By automating the roll forming process, manufacturers can lower labor costs, reduce material waste, and increase output, making the overall production process more cost-effective.

3. Quality and Consistency The precision engineering of roll forming machines ensures that each purlin produced meets strict quality standards. Consistent dimensional accuracy helps prevent issues during assembly and enhances the overall durability of the building framework.

4. Versatility Aside from Z shape purlins, many roll forming machines can be adapted to produce various profiles and components. This versatility allows manufacturers to diversify their product offerings and cater to different market demands.

5. Durability and Strength The use of high-quality materials in conjunction with the roll forming process results in purlins that possess excellent strength-to-weight ratios. This durability makes Z shape purlins ideal for withstanding various environmental conditions.

Conclusion

Z shape purlin roll forming machines play a vital role in the modern construction industry, providing a reliable and efficient method for producing high-quality structural components. With their ability to enhance efficiency, reduce costs, and maintain quality, these machines are integral to meeting the demands of contemporary building projects. As technology continues to advance, we can expect further improvements in roll forming processes, paving the way for even more innovative solutions in structural manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025