Z Purlin Roll Forming Machine Manufacturers and Their Advanced Production Techniques

The Importance of Z Purlin Roll Forming Machines in Modern Construction

In the fast-paced world of construction and manufacturing, efficiency and precision are paramount. One crucial component that has garnered significant attention is the Z purlin roll forming machine. These machines play an essential role in producing Z-shaped purlins that are vital for structural applications in buildings, warehouses, and other infrastructures. This article delves into the functionality, advantages, and considerations when choosing Z purlin roll forming machine factories for your construction needs.

Understanding Z Purlins

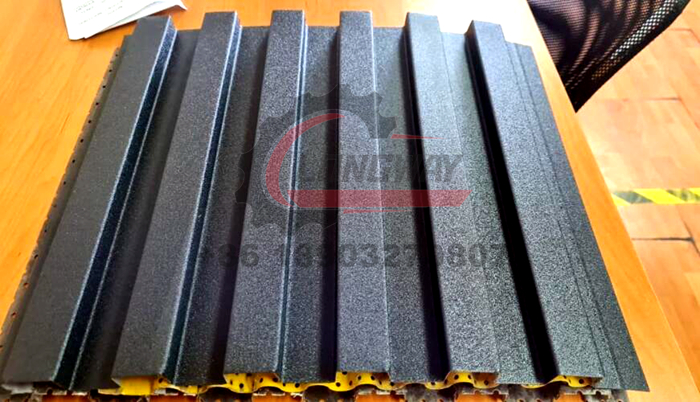

Z purlins are structural elements used mainly in steel-frame buildings. They serve as horizontal supports for roof and wall panels, providing stability and strength while minimizing material usage. Their distinctive Z shape allows for efficient stacking and easy installation alongside other structural members. The demand for Z purlins continues to rise due to the growth of the construction industry and the increasing need for durable building solutions.

Functionality of Z Purlin Roll Forming Machines

Z purlin roll forming machines are specialized equipment designed to roll steel coils into the desired Z profile. The process involves feeding a flat steel coil into the machine, which uses a series of rollers arranged in a specific configuration to gradually shape it into the finished Z purlin. This method ensures high precision, consistent quality, and cost-effectiveness.

The machines often come equipped with features like automatic cutting, hole punching, and curved forming options, allowing manufacturers to produce customized purlins to meet specific project requirements. Additionally, the automation involved in modern roll forming machines leads to reduced labor costs and increased efficiency, making it an attractive investment for any manufacturing facility.

Advantages of Using Z Purlin Roll Forming Machines

1. Cost-Effectiveness Roll forming is highly efficient, which translates to reduced labor and operational costs. The machines can produce large quantities of purlins in a short timeframe, further enhancing profitability.

3. Durability and Quality The process of roll forming ensures that the purlins are made of high-quality steel, resulting in products that are robust and suitable for construction applications. This durability is crucial in ensuring the structural integrity of buildings.

z purlin roll forming machine factories

4. Reduced Waste Roll forming is a material-efficient process, as it minimizes scrap and waste. The machine can utilize the entire width of the steel coil, optimizing material usage and reducing costs associated with waste management.

5. Automation and Precision Modern roll forming machines are often outfitted with advanced automation features, leading to improved precision in the production process. Computer numerical control (CNC) technology helps maintain consistent quality and accuracy.

Choosing the Right Z Purlin Roll Forming Machine Factory

When selecting a factory for Z purlin roll forming machines, several factors must be considered

- Reputation and Expertise Look for factories with a proven track record in manufacturing roll forming machines. Experienced manufacturers are likely to deliver better quality products and support.

- Quality of Machinery Investigate the specifications and quality of machinery used in production. High-quality machines often lead to better performance and durability.

- Customer Support Reliable customer support and after-sales service can significantly influence the efficiency of your operations. Ensure the manufacturer provides adequate training and support.

- Customization Options Depending on your specific needs, it may be essential to choose a manufacturer that offers customization options for their machines.

Conclusion

Z purlin roll forming machines are an indispensable asset for the modern construction industry. With their ability to produce high-quality, customizable purlins efficiently, these machines streamline the construction process, reduce costs, and enhance overall project quality. By choosing the right factory for your Z purlin roll forming machines, you can ensure successful operations and contribute to the ever-evolving landscape of construction. As the demand for sustainable and efficient building practices continues to grow, investing in quality roll forming technology will undoubtedly pay dividends in the long run.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025