z purlin making machine factory

Z Purlin Making Machine Factory Innovating the Future of Construction Fabrication

In the ever-evolving landscape of construction and manufacturing, z purlin making machines have emerged as pivotal tools that redefine efficiency and quality in the production of structural components. As builders and architects seek to maximize the strength and durability of their structures while minimizing costs, the demand for z purlin has surged, necessitating the rise of specialized factories dedicated to innovating these machines. This article dives into the importance of z purlin making machines, the role of factories in manufacturing them, and the potential they hold for the construction industry.

Understanding Z Purlins

Z purlins are horizontal supports used in steel frame buildings that assist in transferring loads from the roof to the walls. Their unique Z shape allows for greater flexibility and strength, making them ideal for a wide range of applications, from industrial buildings to storage structures. Unlike traditional material options, z purlins are both lightweight and sturdy, offering higher tensile strength and resistance to bending. This combination of factors has solidified their place in modern construction practices, highlighting the need for advanced production techniques and reliable manufacturing processes.

The Role of Z Purlin Making Machine Factories

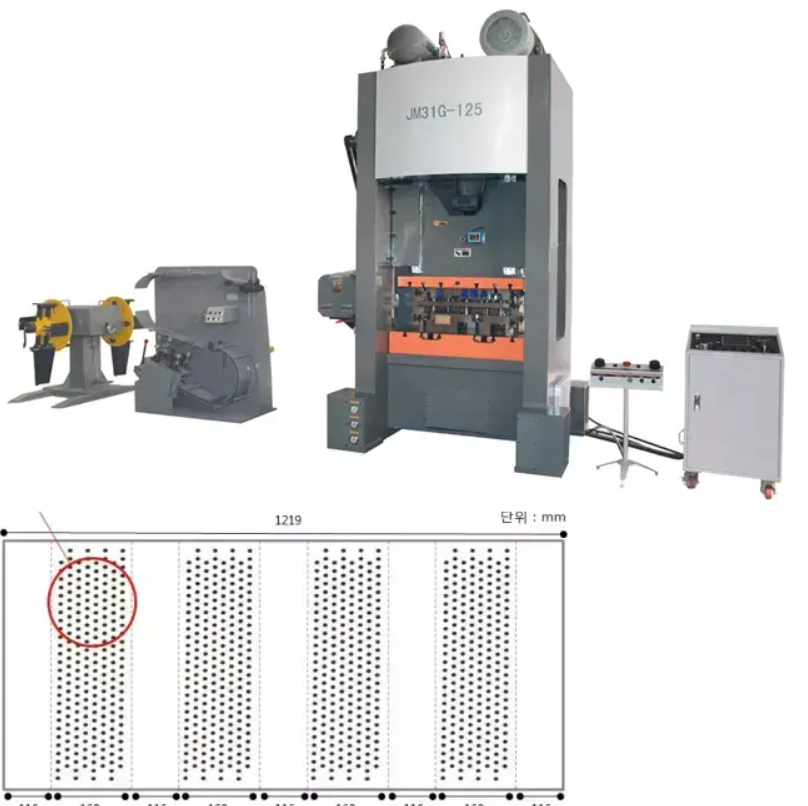

A z purlin making machine factory specializes in the production of machines designed to manufacture z purlins with precision and efficiency. These factories employ cutting-edge technology to ensure that the machines not only meet but exceed industry standards. A typical z purlin making machine operates through a series of technological processes, including material feeding, forming, cutting, and finishing. The inherent design of the machines allows for the production of purlins in various sizes and specifications, accommodating the unique requirements of different projects.

In a factory setting, skilled technicians and engineers collaborate to enhance the manufacturing process. They focus on optimizing operational efficiency, reducing waste, and ensuring the longevity of the machines. Continuous improvement and innovations in design lead to the development of machines that can produce z purlins at an accelerated rate without compromising quality. Furthermore, sophisticated software systems can monitor production in real time, allowing for adjustments to be made swiftly to address any issues that may arise.

Advancements in Technology

z purlin making machine factory

One of the most critical factors contributing to the success of z purlin making machine factories is the integration of advanced technologies such as automation and robotics. Automated systems significantly increase production speeds while maintaining high accuracy. Moreover, the introduction of smart manufacturing techniques, such as IoT (Internet of Things) connectivity, enables machine performance to be tracked remotely, leading to predictive maintenance and reduced downtime.

Another recent innovation includes the use of lightweight, durable materials in the construction of the machines themselves, reducing energy consumption and enhancing overall sustainability. As environmental considerations become increasingly important, z purlin making machine factories are also focusing on eco-friendly practices. From sourcing raw materials responsibly to implementing recycling processes, factories are aligning their operations with global sustainability goals.

The Future of Construction Fabrication

As the construction industry continues to embrace new technologies and methods, the z purlin making machine factory will play a crucial role in shaping the future. The rise of modular construction and pre-fabricated building components is already influencing demand for efficient production systems. Furthermore, with the increasing emphasis on sustainable building practices, z purlin making machines that utilize green technology will gain prominence in the marketplace.

The importance of z purlin making machines cannot be overstated; they are at the forefront of transforming how structures are built, providing efficient solutions to meet the demands of modern construction. Factories dedicated to this purpose are continuously innovating, ensuring that builders have access to high-quality, reliable materials that enhance the durability and functionality of their projects.

Conclusion

The z purlin making machine factory represents a fusion of technology, design, and manufacturing excellence that propels the construction industry forward. As the demand for efficient and reliable construction materials rises, so too does the significance of these specialized factories. By embracing innovation and sustainability, they are not just manufacturing machines; they are building the foundations of the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025