Jan . 30, 2025 04:02

Back to list

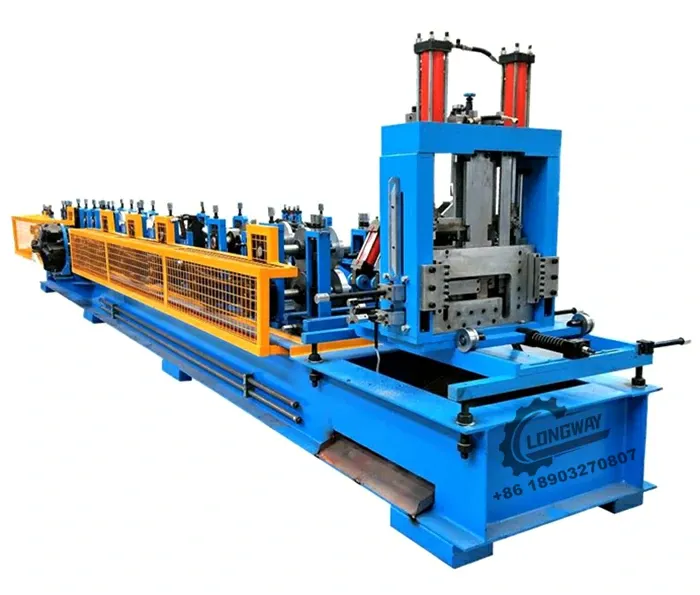

corrugated sheet making machine

Choosing the right zinc sheet making machine is pivotal in the manufacturing process, especially when striving for superior product quality and production efficiency. Zinc sheets are widely used across different industries—from roofing and cladding to automotive parts and industrial equipment. It is, therefore, essential to be equipped with a state-of-the-art machine that aligns with your specific production needs.

Environmental considerations are increasingly critical. Machines with energy-saving features, such as optimized power consumption and recycling capabilities for leftover material, are investments towards sustainable production processes. Not only do they guarantee regulatory compliance, but they also bolster a company's reputation as a responsible and forward-thinking operation. A practical element often underestimated is the adaptability of the machine within a production line. Choosing a model that seamlessly integrates with existing equipment is advantageous. Customizable options or modular designs can allow the machine to fit seamlessly into diverse manufacturing setups, enhancing overall productivity. For those just entering the zinc sheet production market, selecting suppliers with an established reputation provides an additional layer of assurance in terms of both product quality and technical excellence. Testimonials from other users can offer valuable insights into the machine's performance in real-world scenarios, an essential consideration when significant capital investment is on the line. As technology advances, keeping abreast of the latest innovations in zinc sheet making is crucial. Machines that incorporate IoT (Internet of Things) technology for real-time monitoring and predictive maintenance not only boost efficiency but also future-proof your production process against inevitable technological shifts. In a competitive market, making an informed choice about a zinc sheet making machine can distinguish a thriving business from one that struggles to maintain pace. By focusing on technology, durability, sustainability, and support, manufacturers can ensure their processes remain profitable, efficient, and responsible. Prioritizing these aspects ultimately culminates in high-quality output that meets market demands and exceeds customer expectations.

Environmental considerations are increasingly critical. Machines with energy-saving features, such as optimized power consumption and recycling capabilities for leftover material, are investments towards sustainable production processes. Not only do they guarantee regulatory compliance, but they also bolster a company's reputation as a responsible and forward-thinking operation. A practical element often underestimated is the adaptability of the machine within a production line. Choosing a model that seamlessly integrates with existing equipment is advantageous. Customizable options or modular designs can allow the machine to fit seamlessly into diverse manufacturing setups, enhancing overall productivity. For those just entering the zinc sheet production market, selecting suppliers with an established reputation provides an additional layer of assurance in terms of both product quality and technical excellence. Testimonials from other users can offer valuable insights into the machine's performance in real-world scenarios, an essential consideration when significant capital investment is on the line. As technology advances, keeping abreast of the latest innovations in zinc sheet making is crucial. Machines that incorporate IoT (Internet of Things) technology for real-time monitoring and predictive maintenance not only boost efficiency but also future-proof your production process against inevitable technological shifts. In a competitive market, making an informed choice about a zinc sheet making machine can distinguish a thriving business from one that struggles to maintain pace. By focusing on technology, durability, sustainability, and support, manufacturers can ensure their processes remain profitable, efficient, and responsible. Prioritizing these aspects ultimately culminates in high-quality output that meets market demands and exceeds customer expectations.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products