z channel cold roll forming machine

Exploring the Z Channel Cold Roll Forming Machine

In the realm of metalworking and manufacturing, cold roll forming has emerged as a pivotal process, especially for producing components with complex shapes, such as Z channels. The Z channel cold roll forming machine is a specialized piece of equipment designed to create precision-engineered Z channels, which are commonly used in construction, engineering, and various industrial applications.

An Overview of Cold Roll Forming

Cold roll forming is a technique that involves the continuous bending of metal strips at room temperature to create cross-sectional profiles. This method provides several advantages over traditional manufacturing methods, including enhanced strength, superior surface finish, and cost-effectiveness. By utilizing cold roll forming machinery, manufacturers can produce intricate shapes without the need for extensive machining, reducing material waste and labor costs.

The Role of Z Channel in Industry

Z channels, characterized by their Z-shaped cross-section, are fundamental components in structural applications. They are primarily utilized in framing systems, building supports, and various other structural elements. Their design allows for efficient load distribution, making them ideal for use in construction frameworks, racking systems, and even in transportation infrastructures.

Functionality of Z Channel Cold Roll Forming Machines

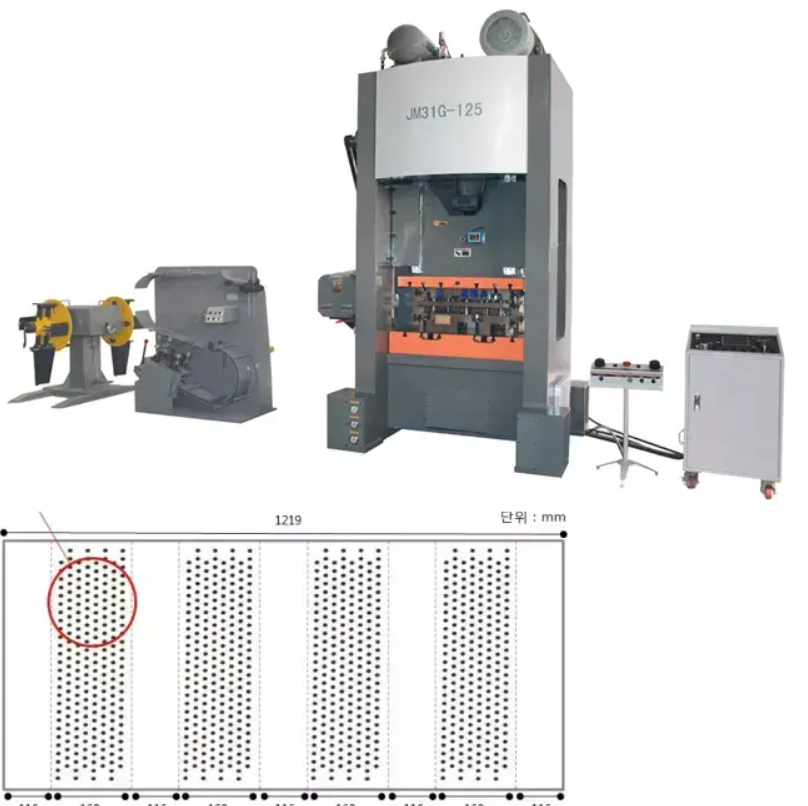

A Z channel cold roll forming machine operates by feeding a strip of metal, typically steel or aluminum, through a series of roller dies. These dies gradually shape the metal into the desired Z profile. The process involves multiple stations, each dedicated to performing specific bending operations.

z channel cold roll forming machine

The major components of a Z channel cold roll forming machine include

1. Material Feeding System This component ensures the continuous and precise feeding of the metal strip into the forming rollers. 2. Forming Rollers These are essential for shaping the strip into the Z profile. Designed with high precision, the rollers can create multiple Z channel specifications. 3. Cutting Mechanism Once the desired length is achieved, a shearing or cutting mechanism will accurately trim the channels as per client requirements. 4. Control System Modern machines are equipped with advanced control technologies that allow operators to set precise dimensions and parameters, ensuring consistent quality throughout production.

Quality and Efficiency

One of the paramount benefits of using a Z channel cold roll forming machine is the high level of dimensional accuracy it provides. The process minimizes inconsistencies and allows for the production of channels with uniform thickness and dimensions. Moreover, as this machine operates cold, the inherent properties of the metal remain intact, enhancing the product's tensile strength and durability.

Applications and Market Demand

The demand for Z channels has surged across industries due to their versatility. In the construction sector, they are vital for building frameworks, while in the manufacturing industry, they are used for creating supports, brackets, and other components. As infrastructure projects continue to grow globally, the need for Z channel cold roll forming machines is expected to rise.

In conclusion, the Z channel cold roll forming machine stands as a testament to the advancements in metal forming technology. It not only streamlines production but also ensures the quality and durability of the components produced. As industries evolve, this machine will undoubtedly play a crucial role in meeting the needs of modern manufacturing and construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025