window frame roll forming machine

The Evolution and Significance of Window Frame Roll Forming Machines

In the modern manufacturing landscape, efficiency and precision are key factors that define success. Among the various industrial processes that contribute to producing high-quality components, roll forming stands out, particularly when it comes to creating window frames. Window frame roll forming machines are specialized equipment designed to produce frames with exceptional accuracy and consistency, which are critical for both aesthetic appeal and structural integrity.

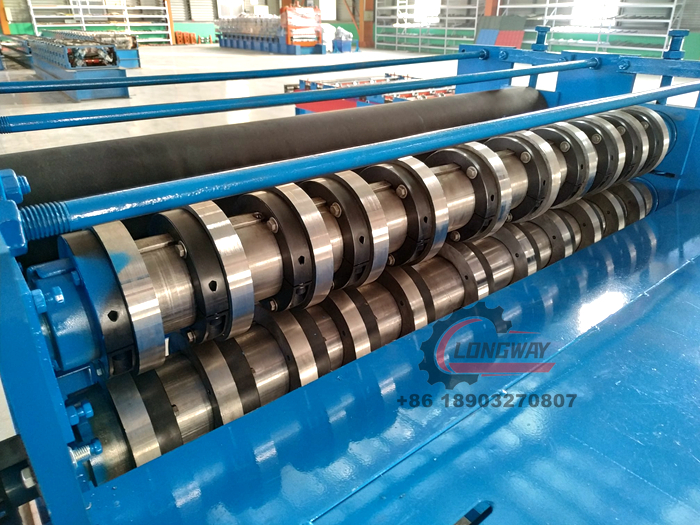

Understanding Roll Forming Process

Roll forming is a continuous bending operation in which a long strip of metal, typically steel or aluminum, is passed through a series of rollers to achieve a desired cross-sectional profile. This process is particularly advantageous for producing long lengths of uniform shapes, making it ideal for window frames that require various designs and dimensions. The technique minimizes waste and maximizes efficiency, presenting a more sustainable approach compared to traditional methods, such as cutting and welding.

Advantages of Window Frame Roll Forming Machines

One of the primary benefits of using roll forming machines for window frame production is the high production rate. These machines can operate continuously, allowing manufacturers to produce large quantities of window frames in a relatively short period. This is essential for meeting market demands and maintaining competitive pricing.

Moreover, the precision offered by roll forming machines is unparalleled. The process ensures that every frame produced has consistent dimensions, which is vital for ensuring the seamless installation of windows. Variability in frame dimensions can lead to significant installation challenges, thereby affecting energy efficiency and the overall performance of the windows.

Another significant advantage is the material efficiency associated with roll forming. The process allows for the use of thinner gauge materials without compromising strength, leading to cost savings in raw material procurement. Additionally, the elimination of secondary operations, such as cutting and welding, not only reduces labor costs but also minimizes the carbon footprint associated with production.

window frame roll forming machine

Applications in the Window Manufacturing Industry

The versatility of window frame roll forming machines makes them suitable for a wide variety of applications. Manufacturers can produce frames for residential, commercial, and industrial buildings. In residential construction, aesthetically pleasing frames with intricate designs can be manufactured, catering to consumers’ aesthetic preferences. In commercial applications, frames that provide enhanced durability and protection against environmental elements can be produced, ensuring longevity and reliability.

The ability to adapt to different materials is another significant feature of these machines. While aluminum and steel are the two most common materials used, advancements in technology have allowed for the integration of other materials, offering more choices for builders and homeowners alike.

Technological Innovations

As technology evolves, so does the functionality of window frame roll forming machines. Many modern units are equipped with advanced automation systems, making them easier to operate and enhancing production versatility. Computer Numerical Control (CNC) technology allows for precise adjustments and rapid changeovers between different product specifications, reducing downtime and increasing overall productivity.

Furthermore, the integration of smart technology into roll forming machines enables real-time monitoring of the manufacturing process. This feature helps identify potential issues before they cause significant disruptions, further enhancing efficiency and product quality.

Conclusion

In summary, window frame roll forming machines play a pivotal role in the manufacturing industry, delivering efficiency, precision, and sustainability. As the demand for high-quality window frames continues to grow, these machines will undoubtedly adapt and evolve further, incorporating innovative technology that will streamline production processes and enhance the overall quality of the end product. As we move into a future where energy efficiency and sustainable practices are paramount, the role of roll forming in producing window frames is set to become even more significant, solidifying its status as a cornerstone of modern manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025