Jan . 14, 2025 10:24

Back to list

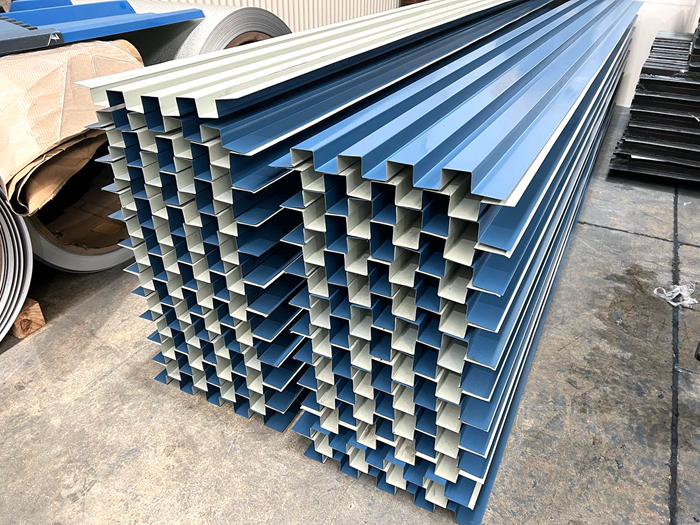

Width adjustable soffit panel roll forming machine

The soffit roll forming machine stands as a pivotal innovation in the realm of construction and manufacturing, offering unparalleled precision and efficiency. This equipment, renowned for its ability to fabricate continuous soffit panels, has transformed traditional practices, seamlessly blending technological sophistication with user-friendly design.

Sustainability is also a noteworthy advantage of using a soffit roll forming machine. The precision in cutting and forming reduces raw material wastage, ensuring that production is both environmentally friendly and cost-effective. This is particularly beneficial in today's industry, where there's a pressing need to adopt greener manufacturing practices. From a technical standpoint, operating a soffit roll forming machine does not require extensive training. Many machines come equipped with user-friendly interfaces that provide step-by-step guides and troubleshooting support. This accessibility makes the technology available even to manufacturing units that may not have specialized technicians at hand, democratizing the benefits of advanced manufacturing. Ultimately, investing in a soffit roll forming machine bolsters a company's competitive edge. Not only does it enhance the quality and consistency of soffit panels, but it also positions the business as a leader in innovative manufacturing solutions. In a market that increasingly values precision and sustainability, having the right equipment can make a significant difference. In conclusion, the soffit roll forming machine is not merely a piece of equipment; it is a catalyst for growth and innovation in the construction and manufacturing industries. Its precision, efficiency, and adaptability make it a valuable asset for any company looking to advance their production capabilities and meet the ever-evolving demands of the modern market.

Sustainability is also a noteworthy advantage of using a soffit roll forming machine. The precision in cutting and forming reduces raw material wastage, ensuring that production is both environmentally friendly and cost-effective. This is particularly beneficial in today's industry, where there's a pressing need to adopt greener manufacturing practices. From a technical standpoint, operating a soffit roll forming machine does not require extensive training. Many machines come equipped with user-friendly interfaces that provide step-by-step guides and troubleshooting support. This accessibility makes the technology available even to manufacturing units that may not have specialized technicians at hand, democratizing the benefits of advanced manufacturing. Ultimately, investing in a soffit roll forming machine bolsters a company's competitive edge. Not only does it enhance the quality and consistency of soffit panels, but it also positions the business as a leader in innovative manufacturing solutions. In a market that increasingly values precision and sustainability, having the right equipment can make a significant difference. In conclusion, the soffit roll forming machine is not merely a piece of equipment; it is a catalyst for growth and innovation in the construction and manufacturing industries. Its precision, efficiency, and adaptability make it a valuable asset for any company looking to advance their production capabilities and meet the ever-evolving demands of the modern market.

Latest news

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025

Related Products