What is “Roll Forming?”-roll forming machine

The term “roll forming” lends itself to great ambiguity.

Since steel mills producing “long sections” of structural steel–including angles, bars, beams, channels, and tees–manufacture their products through a rolling process, these sections are often referred to as, for example, “rolled beams.” (In part to distinguish them from built-up girders, i.e. beams made by welding three pieces together.)

Light steel ceiling CU channel roll forming machine

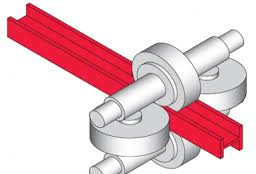

And these straight sections are often curved to a given radius, in a prescribed orientation, through a given number of degrees or a given arc length to be used in a variety of applications. Since the most common way of curving structural steel involves three-roll benders (also called “angle rolls,” “section benders,” and “pyramid rolls”) bending with these machines could also be called “roll forming.”

In construction, curved steel beams, for example, are often used as roof supports, canopies, and bridges; in manufacturing, curved steel sections are used in tractors, antennas, rail cars, and tanks–to name just a few applications.

But perhaps the most common use of the term “roll forming” refers to a process whereby a strip of sheet metal or relatively light plate is fed off a coil into a series of rollers which progressively form the desired shape. The method has been used to form residential gutters whose length is limited only by the length of the metal in the steel or aluminum coil. The gutters can be formed to length in a truck at the job site. This type of roll forming is most commonly used to produce many feet of a formed product whether that be angles, channels, tees, etc.

At the heavier end, roll forming of plate is a process that produces, among other products, Hollow Structural Sections (HSS). Again, the plate is most often fed into rolls from steel coils. Through a series of rolls, the plate is progressively formed into a quarter cylinder, then a half cylinder, then into a full round tube, and then the seam is welded. Some tube mills then have more forming rolls that shape the round tube into square or rectangular tubes. Other tube mills form square and rectangular tubes which are welded after being formed into the square or rectangular shape. (They skip the interim step of forming and welding round tube.)

When exploring the various options available for a given application, you should first clarify with any supplier what the final part will look like. Will the “roll forming” provide straight steel sections? If so, then you should be talking either to steel mills, to their distributors, or to roll-formers who make straight formed sections from coils of steel. If the final part will have a curve, then you should be talking to a “roller/bender”, a company that curves steel that comes into its shop in a straight condition from a steel mill, from a service center, or even from a “roll former”.