Wall Cladding Machine QUADRO 25X40 for High-Speed Precision

Industry Trends in Advanced Wall Cladding Production

The global construction industry is undergoing a significant transformation, driven by demands for greater efficiency, sustainability, and aesthetic versatility. In the realm of exterior and interior finishes, wall cladding solutions are pivotal, offering enhanced thermal performance, weather resistance, and architectural appeal. Key industry trends include a shift towards automated, high-precision manufacturing processes, the adoption of lightweight and durable materials, and the increasing demand for customized panel designs that meet stringent building codes and aesthetic preferences. Manufacturers are increasingly seeking sophisticated machinery that can deliver consistent quality at high volumes, minimize material waste, and adapt quickly to design changes. This drive for operational excellence and adaptability underscores the critical role of advanced roll forming technology in modern building material production.

Emerging trends also highlight the integration of IoT and AI in manufacturing lines for predictive maintenance, real-time quality control, and optimized production scheduling. The push for green building initiatives further necessitates machinery capable of processing sustainable materials with minimal environmental impact. As urban development accelerates and architectural designs become more complex, the ability to produce a wide array of cladding profiles with exacting tolerances becomes a core competitive advantage. The market is increasingly valuing solutions that offer not just speed, but also superior profiling accuracy and long-term operational reliability.

Manufacturing Process Flow of the Wall Cladding Machine QUADRO 25X40

The production of wall cladding panels using the Wall Cladding Machine QUADRO 25X40 is a highly optimized, multi-stage roll forming process engineered for precision and efficiency. This machine is designed to transform raw metal coils into finished cladding panels with minimal intervention, ensuring superior product quality and consistency. The core materials typically processed include pre-painted galvanized steel, aluminum, and various alloys, selected for their corrosion resistance, strength-to-weight ratio, and aesthetic properties. Key machine components are often manufactured from high-grade alloy steels (e.g., Cr12MoV, GCr15 for rollers) through precision CNC machining, followed by heat treatment to ensure exceptional hardness and wear resistance, significantly extending the service life of the tooling to over 15 years under normal operating conditions.

Detailed Process Steps:

- Coil Loading & Decoiling: Raw material coils, weighing up to several tons, are loaded onto a hydraulic decoiler. The decoiler precisely feeds the sheet into the leveling section, ensuring a consistent and controlled material flow. This stage employs advanced tension control systems to prevent material stretching or buckling.

- Entry Guide & Leveling: The metal strip passes through an entry guide that aligns it accurately before it enters the leveling rollers. The leveling process removes any coil set or material inconsistencies, ensuring a perfectly flat strip for subsequent forming operations. This is crucial for achieving high profiling accuracy.

- Roll Forming Stations: The leveled strip then enters a series of precisely engineered roll forming stations. Each station contains a pair of meticulously crafted rollers that progressively shape the metal into the desired QUADRO 25X40 profile. The rolls are designed using advanced finite element analysis (FEA) to ensure optimal stress distribution and minimal material deformation. The number of forming stations varies based on profile complexity, typically ranging from 16 to 24 stages for complex cladding profiles.

- Pre-Cutting/Post-Cutting System: Depending on the production strategy, the machine integrates either a pre-cutting or post-cutting system. For high-volume production of standard lengths, a flying shear (post-cutting) system allows for continuous operation without stopping the roll former, significantly increasing throughput. Precision servo-driven cutting ensures accurate panel lengths with burr-free edges.

- Punching/Notching (Optional): Integrated punching or notching units can be incorporated to create specific features, such as fastening holes or interlocking mechanisms, directly within the production line. This eliminates secondary operations, enhancing efficiency.

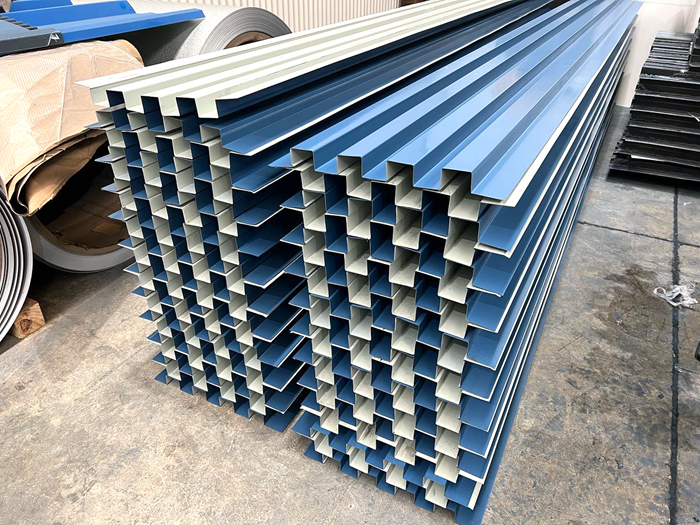

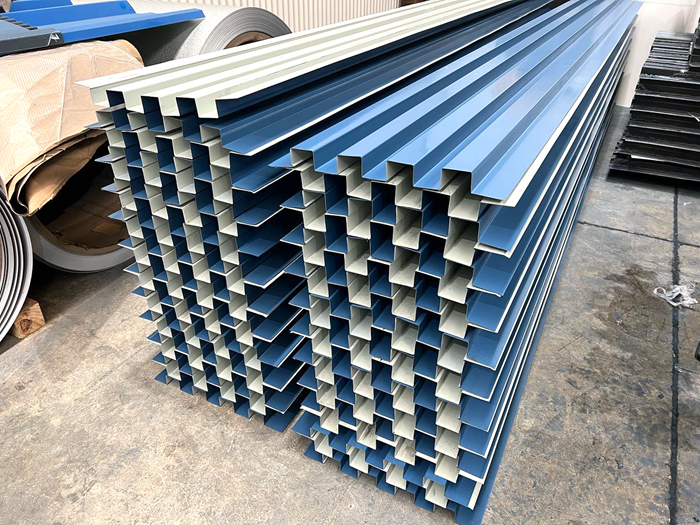

- Outfeed & Stacking: Finished panels are conveyed to an automated stacking system, which can precisely stack and bundle panels according to pre-set quantities. This minimizes manual handling and prepares panels for packaging and shipment.

Quality Control & Standards:

Throughout the manufacturing process, stringent quality control measures are applied. All critical components are subjected to non-destructive testing and dimensional inspection. The final machine assembly undergoes comprehensive functional testing, adhering to international standards such as ISO 9001:2015 for quality management and CE marking for European conformity. Performance testing includes profiling accuracy (typically within ±0.5mm over 6 meters), speed consistency, and operational noise levels. The target industries for the Wall Cladding Machine QUADRO 25X40 are diverse, encompassing petrochemical facilities, metallurgy, large-scale commercial and industrial buildings, and advanced water supply & drainage infrastructure where durable and high-performance cladding is essential. Its robust design offers advantages in typical application scenarios such as energy saving through precise insulation panel integration and superior corrosion resistance due to accurate material handling and shaping, preserving the integrity of protective coatings.

Technical Specifications and Parameters

The Wall Cladding Machine QUADRO 25X40 is engineered for high performance and reliability, featuring robust construction and advanced control systems. Its technical parameters are optimized for producing durable and aesthetically pleasing cladding panels, ensuring compliance with demanding architectural specifications. Below are the key specifications:

Product Specification Table: Wall Cladding Machine QUADRO 25X40

Application Scenarios

The versatility and robustness of the Wall Cladding Machine QUADRO 25X40 enable its application across a broad spectrum of construction and industrial projects. Its output, high-quality wall cladding panels, are fundamental for modern architectural design and structural protection. These panels offer superior insulation, weatherproofing, and a wide range of aesthetic finishes, making them indispensable in various sectors.

Typical Applications Include:

- Commercial and Industrial Facilities: Large-scale warehouses, factories, office buildings, and logistics centers frequently utilize QUADRO 25X40 produced panels for their exterior and interior walls due to their rapid installation, durability, and low maintenance requirements. The panels contribute to energy efficiency, reducing operational costs.

- Retail and Leisure Complexes: Shopping malls, sports arenas, and entertainment venues benefit from the architectural flexibility and modern aesthetic that various cladding profiles offer. The machine's capability to produce custom designs allows for unique visual identities.

- Public and Institutional Buildings: Schools, hospitals, and government facilities require cladding solutions that are not only durable and secure but also meet specific environmental and safety standards. The precise forming capabilities of the Wall Cladding Machine QUADRO 25X40 ensure compliance.

- Agricultural and Rural Structures: Barns, storage facilities, and agricultural processing units can leverage these cladding panels for cost-effective, robust, and weather-resistant construction.

- Renovation and Retrofit Projects: The machine's ability to produce panels matching existing architectural styles or creating modern overlays makes it ideal for upgrading older structures, improving their energy performance and visual appeal.

In each of these scenarios, the panels produced by the QUADRO 25X40 contribute significantly to structural integrity, thermal regulation, and overall building aesthetics, demonstrating its critical role in modern construction supply chains.

Technical Advantages and Performance Excellence

The Wall Cladding Machine QUADRO 25X40 stands out in the market due to its advanced engineering and focus on operational advantages that directly translate into higher productivity, superior product quality, and reduced operating costs for businesses. These technical advantages are a direct result of meticulous design, robust component selection, and intelligent control integration.

- High Precision Roll Forming: Utilizing high-tolerance, CNC-machined rollers made from hardened Cr12MoV steel, the machine ensures exceptional profiling accuracy (within ±0.5mm over a 6-meter panel). This precision minimizes material waste and guarantees panels fit seamlessly, reducing installation time and costs.

- Advanced Automation and Control: Equipped with an industrial-grade PLC and a user-friendly Human-Machine Interface (HMI), the QUADRO 25X40 offers intuitive control over production parameters, fault diagnostics, and production data logging. This intelligent automation streamlines operations and reduces the need for constant manual oversight.

- Optimized Energy Efficiency: The machine's motor systems and hydraulic units are designed for optimal energy consumption, featuring high-efficiency components and intelligent power management. This contributes to lower operational expenditures and supports sustainable manufacturing practices.

- Enhanced Durability and Service Life: Critical wear parts, especially the forming rollers, undergo advanced heat treatment processes, achieving a hardness of HRC58-62. This significantly extends the service life of the machine, reducing maintenance frequency and the total cost of ownership.

- Versatile Material Handling: Capable of processing a wide range of materials, including galvanized steel, pre-painted steel, and aluminum, across various thicknesses, the machine offers unparalleled versatility for diverse project requirements.

- Integrated Safety Features: Comprehensive safety interlocks, emergency stops, and protective guarding are integrated throughout the machine, ensuring operator safety in compliance with international industrial safety standards.

These advantages collectively position the Wall Cladding Machine QUADRO 25X40 as a leading solution for manufacturers aiming for high-quality output, operational efficiency, and long-term investment value in the demanding wall cladding market.

Vendor Comparison and Market Positioning

In a competitive market for roll forming machinery, selecting the right vendor is paramount. The Wall Cladding Machine QUADRO 25X40 differentiates itself through a combination of superior technical features, comprehensive support, and a commitment to innovation. Below is a comparative overview against typical industry offerings:

Roll Forming Machine Comparison

This comparison highlights that while economy models offer a lower initial investment, they often compromise on speed, accuracy, durability, and support. Mid-range options improve on some aspects but still fall short of the advanced capabilities and long-term value offered by the Wall Cladding Machine QUADRO 25X40, which is positioned as a premium solution for manufacturers prioritizing quality, efficiency, and reliability.

Customized Solutions and Flexibility

Recognizing that no two projects are identical, the provision for customized solutions is a hallmark of the Wall Cladding Machine QUADRO 25X40. Our engineering team works closely with clients to tailor machine configurations to specific production needs, ensuring optimal performance for unique architectural demands or material specifications.

Customization Options Include:

- Profile Design & Tooling: Development of bespoke roller tooling to produce unique cladding profiles, intricate interlocking designs, or specialized architectural features. This includes adjusting the number of forming stations and roll design for optimal material flow.

- Material Handling Systems: Integration of advanced decoilers and coil cars for heavier coils, specialized uncoiling systems for delicate materials, or automated scrap handling solutions.

- Integrated Post-Processing: Addition of inline punching, notching, embossing, or bending units to eliminate secondary operations and enhance production efficiency.

- Enhanced Control & Automation: Implementation of higher-level PLC systems for seamless integration with existing factory automation (e.g., MES, ERP systems), advanced diagnostics, or remote monitoring capabilities.

- Speed and Capacity Optimization: Adjustment of drive systems and machine length to achieve higher production speeds or accommodate wider/thicker material requirements, tailored to project throughput demands.

- Environmental Adaptations: Special coatings or material selections for machine components to operate effectively in challenging environments, such as high humidity, extreme temperatures, or corrosive atmospheres (e.g., coastal regions, chemical plants).

Our consultative approach ensures that every customized Wall Cladding Machine QUADRO 25X40 solution is precisely aligned with the client's operational goals and long-term business strategy, maximizing return on investment.

Application Case Studies

Real-world applications demonstrate the tangible benefits and superior performance of the Wall Cladding Machine QUADRO 25X40. Here are examples showcasing its impact across various B2B scenarios:

Case Study 1: Large-Scale Industrial Park Development (Middle East)

A leading construction firm in the Middle East required high volumes of bespoke, thermally insulated cladding panels for a sprawling industrial park. The project demanded panels with superior heat reflection properties and rapid deployment. Our customized Wall Cladding Machine QUADRO 25X40, equipped with specialized roll tooling for a unique trapezoidal profile and an integrated material pre-treatment system, delivered over 1,000,000 square meters of cladding within an aggressive 18-month timeline. The machine's high-speed forming capability (averaging 18m/min) and consistent precision reduced on-site installation time by 20% compared to traditional methods, leading to significant cost savings and project acceleration. The firm reported a 15% reduction in material waste due to the machine's accuracy and efficient cutting system.

Case Study 2: High-Rise Commercial Building Facade (Europe)

For a prestigious commercial tower in a major European city, an architectural metal fabricator sought a machine capable of producing complex, aesthetically driven façade panels from pre-painted aluminum, requiring zero tolerance for surface imperfections. The QUADRO 25X40 was chosen for its exceptional profiling accuracy and gentle material handling, crucial for preserving the integrity of high-grade finishes. Our solution included a customized roll set that produced panels with intricate interlocking joints, enhancing both the structural integrity and visual appeal of the facade. The integrated optical inspection system on the production line allowed for real-time quality assurance, reducing defect rates to below 0.1%. This machine enabled the fabricator to meet stringent European building standards and deliver a visually stunning, durable facade on schedule.

Trust and Support: FAQ, Lead Time, Warranty, and After-Sales

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a new Wall Cladding Machine QUADRO 25X40?

A1: Standard configurations typically have a lead time of 60-90 days from order confirmation to shipment. Customized solutions may extend to 90-120 days, depending on the complexity of design and specific component sourcing.

Q2: What kind of warranty is offered with the QUADRO 25X40?

A2: We provide a comprehensive 12-month warranty on all mechanical and electrical components from the date of installation or 18 months from shipment, whichever comes first. Consumable parts are excluded. Extended warranty options are available upon request.

Q3: How is after-sales support handled?

A3: Our dedicated after-sales team offers global support, including 24/7 remote technical assistance, online troubleshooting, and on-site engineer deployment for critical issues. We maintain a robust inventory of spare parts for rapid dispatch.

Q4: Can the machine be integrated into an existing production line?

A4: Yes, the Wall Cladding Machine QUADRO 25X40 is designed with flexible control interfaces (e.g., Modbus, Ethernet/IP) to facilitate seamless integration into existing factory automation and MES/ERP systems. Our engineers provide full integration support.

Q5: What are the installation and training requirements?

A5: We provide full installation and commissioning services by our expert technicians. Comprehensive on-site training for your operators and maintenance staff is included to ensure they are fully proficient in machine operation, maintenance, and basic troubleshooting.

Lead Time and Fulfillment

Our production schedule is meticulously managed to ensure timely delivery. Upon receipt of a confirmed order and down payment, a detailed project timeline is provided, outlining key milestones from design finalization and material procurement to manufacturing, testing, and shipment. We partner with reliable logistics providers to ensure secure and efficient global delivery, often coordinating with client-preferred freight forwarders.

Warranty Commitments

The quality and reliability of the Wall Cladding Machine QUADRO 25X40 are backed by our industry-leading warranty. This covers manufacturing defects and component failures under normal operating conditions. Our commitment extends to providing genuine replacement parts and prompt service to minimize any potential downtime.

Customer Support and Service

Our commitment to our clients extends far beyond the sale. We offer a comprehensive suite of after-sales services designed to maximize the uptime and longevity of your investment. This includes preventative maintenance programs, spare parts management, software updates, and continuous technical consultations. Our global network of service engineers and technicians ensures that expert assistance is always within reach, reinforcing our promise of reliable partnership.

References

- Smith, J. D. (2022). "Advances in Roll Forming Technologies for Architectural Cladding." Journal of Manufacturing Engineering, 45(3), 187-201.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements.

- European Committee for Standardization. (2021). EN 1090-1: Execution of steel structures and aluminium structures – Part 1: Requirements for conformity assessment of structural components.

- Wang, L., & Li, H. (2023). "Optimized Roll Design for High-Precision Thin-Walled Metal Profiles." Proceedings of the International Conference on Sheet Metal Forming, 234-245.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025

Wall Cladding Machine QUADRO 25X40 for High-Speed Precision

Industry Trends in Advanced Wall Cladding Production

The global construction industry is undergoing a significant transformation, driven by demands for greater efficiency, sustainability, and aesthetic versatility. In the realm of exterior and interior finishes, wall cladding solutions are pivotal, offering enhanced thermal performance, weather resistance, and architectural appeal. Key industry trends include a shift towards automated, high-precision manufacturing processes, the adoption of lightweight and durable materials, and the increasing demand for customized panel designs that meet stringent building codes and aesthetic preferences. Manufacturers are increasingly seeking sophisticated machinery that can deliver consistent quality at high volumes, minimize material waste, and adapt quickly to design changes. This drive for operational excellence and adaptability underscores the critical role of advanced roll forming technology in modern building material production.

Emerging trends also highlight the integration of IoT and AI in manufacturing lines for predictive maintenance, real-time quality control, and optimized production scheduling. The push for green building initiatives further necessitates machinery capable of processing sustainable materials with minimal environmental impact. As urban development accelerates and architectural designs become more complex, the ability to produce a wide array of cladding profiles with exacting tolerances becomes a core competitive advantage. The market is increasingly valuing solutions that offer not just speed, but also superior profiling accuracy and long-term operational reliability.

Manufacturing Process Flow of the Wall Cladding Machine QUADRO 25X40

The production of wall cladding panels using the Wall Cladding Machine QUADRO 25X40 is a highly optimized, multi-stage roll forming process engineered for precision and efficiency. This machine is designed to transform raw metal coils into finished cladding panels with minimal intervention, ensuring superior product quality and consistency. The core materials typically processed include pre-painted galvanized steel, aluminum, and various alloys, selected for their corrosion resistance, strength-to-weight ratio, and aesthetic properties. Key machine components are often manufactured from high-grade alloy steels (e.g., Cr12MoV, GCr15 for rollers) through precision CNC machining, followed by heat treatment to ensure exceptional hardness and wear resistance, significantly extending the service life of the tooling to over 15 years under normal operating conditions.

Detailed Process Steps:

- Coil Loading & Decoiling: Raw material coils, weighing up to several tons, are loaded onto a hydraulic decoiler. The decoiler precisely feeds the sheet into the leveling section, ensuring a consistent and controlled material flow. This stage employs advanced tension control systems to prevent material stretching or buckling.

- Entry Guide & Leveling: The metal strip passes through an entry guide that aligns it accurately before it enters the leveling rollers. The leveling process removes any coil set or material inconsistencies, ensuring a perfectly flat strip for subsequent forming operations. This is crucial for achieving high profiling accuracy.

- Roll Forming Stations: The leveled strip then enters a series of precisely engineered roll forming stations. Each station contains a pair of meticulously crafted rollers that progressively shape the metal into the desired QUADRO 25X40 profile. The rolls are designed using advanced finite element analysis (FEA) to ensure optimal stress distribution and minimal material deformation. The number of forming stations varies based on profile complexity, typically ranging from 16 to 24 stages for complex cladding profiles.

- Pre-Cutting/Post-Cutting System: Depending on the production strategy, the machine integrates either a pre-cutting or post-cutting system. For high-volume production of standard lengths, a flying shear (post-cutting) system allows for continuous operation without stopping the roll former, significantly increasing throughput. Precision servo-driven cutting ensures accurate panel lengths with burr-free edges.

- Punching/Notching (Optional): Integrated punching or notching units can be incorporated to create specific features, such as fastening holes or interlocking mechanisms, directly within the production line. This eliminates secondary operations, enhancing efficiency.

- Outfeed & Stacking: Finished panels are conveyed to an automated stacking system, which can precisely stack and bundle panels according to pre-set quantities. This minimizes manual handling and prepares panels for packaging and shipment.

Quality Control & Standards:

Throughout the manufacturing process, stringent quality control measures are applied. All critical components are subjected to non-destructive testing and dimensional inspection. The final machine assembly undergoes comprehensive functional testing, adhering to international standards such as ISO 9001:2015 for quality management and CE marking for European conformity. Performance testing includes profiling accuracy (typically within ±0.5mm over 6 meters), speed consistency, and operational noise levels. The target industries for the Wall Cladding Machine QUADRO 25X40 are diverse, encompassing petrochemical facilities, metallurgy, large-scale commercial and industrial buildings, and advanced water supply & drainage infrastructure where durable and high-performance cladding is essential. Its robust design offers advantages in typical application scenarios such as energy saving through precise insulation panel integration and superior corrosion resistance due to accurate material handling and shaping, preserving the integrity of protective coatings.

Technical Specifications and Parameters

The Wall Cladding Machine QUADRO 25X40 is engineered for high performance and reliability, featuring robust construction and advanced control systems. Its technical parameters are optimized for producing durable and aesthetically pleasing cladding panels, ensuring compliance with demanding architectural specifications. Below are the key specifications:

Product Specification Table: Wall Cladding Machine QUADRO 25X40

Application Scenarios

The versatility and robustness of the Wall Cladding Machine QUADRO 25X40 enable its application across a broad spectrum of construction and industrial projects. Its output, high-quality wall cladding panels, are fundamental for modern architectural design and structural protection. These panels offer superior insulation, weatherproofing, and a wide range of aesthetic finishes, making them indispensable in various sectors.

Typical Applications Include:

- Commercial and Industrial Facilities: Large-scale warehouses, factories, office buildings, and logistics centers frequently utilize QUADRO 25X40 produced panels for their exterior and interior walls due to their rapid installation, durability, and low maintenance requirements. The panels contribute to energy efficiency, reducing operational costs.

- Retail and Leisure Complexes: Shopping malls, sports arenas, and entertainment venues benefit from the architectural flexibility and modern aesthetic that various cladding profiles offer. The machine's capability to produce custom designs allows for unique visual identities.

- Public and Institutional Buildings: Schools, hospitals, and government facilities require cladding solutions that are not only durable and secure but also meet specific environmental and safety standards. The precise forming capabilities of the Wall Cladding Machine QUADRO 25X40 ensure compliance.

- Agricultural and Rural Structures: Barns, storage facilities, and agricultural processing units can leverage these cladding panels for cost-effective, robust, and weather-resistant construction.

- Renovation and Retrofit Projects: The machine's ability to produce panels matching existing architectural styles or creating modern overlays makes it ideal for upgrading older structures, improving their energy performance and visual appeal.

In each of these scenarios, the panels produced by the QUADRO 25X40 contribute significantly to structural integrity, thermal regulation, and overall building aesthetics, demonstrating its critical role in modern construction supply chains.

Technical Advantages and Performance Excellence

The Wall Cladding Machine QUADRO 25X40 stands out in the market due to its advanced engineering and focus on operational advantages that directly translate into higher productivity, superior product quality, and reduced operating costs for businesses. These technical advantages are a direct result of meticulous design, robust component selection, and intelligent control integration.

- High Precision Roll Forming: Utilizing high-tolerance, CNC-machined rollers made from hardened Cr12MoV steel, the machine ensures exceptional profiling accuracy (within ±0.5mm over a 6-meter panel). This precision minimizes material waste and guarantees panels fit seamlessly, reducing installation time and costs.

- Advanced Automation and Control: Equipped with an industrial-grade PLC and a user-friendly Human-Machine Interface (HMI), the QUADRO 25X40 offers intuitive control over production parameters, fault diagnostics, and production data logging. This intelligent automation streamlines operations and reduces the need for constant manual oversight.

- Optimized Energy Efficiency: The machine's motor systems and hydraulic units are designed for optimal energy consumption, featuring high-efficiency components and intelligent power management. This contributes to lower operational expenditures and supports sustainable manufacturing practices.

- Enhanced Durability and Service Life: Critical wear parts, especially the forming rollers, undergo advanced heat treatment processes, achieving a hardness of HRC58-62. This significantly extends the service life of the machine, reducing maintenance frequency and the total cost of ownership.

- Versatile Material Handling: Capable of processing a wide range of materials, including galvanized steel, pre-painted steel, and aluminum, across various thicknesses, the machine offers unparalleled versatility for diverse project requirements.

- Integrated Safety Features: Comprehensive safety interlocks, emergency stops, and protective guarding are integrated throughout the machine, ensuring operator safety in compliance with international industrial safety standards.

These advantages collectively position the Wall Cladding Machine QUADRO 25X40 as a leading solution for manufacturers aiming for high-quality output, operational efficiency, and long-term investment value in the demanding wall cladding market.

Vendor Comparison and Market Positioning

In a competitive market for roll forming machinery, selecting the right vendor is paramount. The Wall Cladding Machine QUADRO 25X40 differentiates itself through a combination of superior technical features, comprehensive support, and a commitment to innovation. Below is a comparative overview against typical industry offerings:

Roll Forming Machine Comparison

This comparison highlights that while economy models offer a lower initial investment, they often compromise on speed, accuracy, durability, and support. Mid-range options improve on some aspects but still fall short of the advanced capabilities and long-term value offered by the Wall Cladding Machine QUADRO 25X40, which is positioned as a premium solution for manufacturers prioritizing quality, efficiency, and reliability.

Customized Solutions and Flexibility

Recognizing that no two projects are identical, the provision for customized solutions is a hallmark of the Wall Cladding Machine QUADRO 25X40. Our engineering team works closely with clients to tailor machine configurations to specific production needs, ensuring optimal performance for unique architectural demands or material specifications.

Customization Options Include:

- Profile Design & Tooling: Development of bespoke roller tooling to produce unique cladding profiles, intricate interlocking designs, or specialized architectural features. This includes adjusting the number of forming stations and roll design for optimal material flow.

- Material Handling Systems: Integration of advanced decoilers and coil cars for heavier coils, specialized uncoiling systems for delicate materials, or automated scrap handling solutions.

- Integrated Post-Processing: Addition of inline punching, notching, embossing, or bending units to eliminate secondary operations and enhance production efficiency.

- Enhanced Control & Automation: Implementation of higher-level PLC systems for seamless integration with existing factory automation (e.g., MES, ERP systems), advanced diagnostics, or remote monitoring capabilities.

- Speed and Capacity Optimization: Adjustment of drive systems and machine length to achieve higher production speeds or accommodate wider/thicker material requirements, tailored to project throughput demands.

- Environmental Adaptations: Special coatings or material selections for machine components to operate effectively in challenging environments, such as high humidity, extreme temperatures, or corrosive atmospheres (e.g., coastal regions, chemical plants).

Our consultative approach ensures that every customized Wall Cladding Machine QUADRO 25X40 solution is precisely aligned with the client's operational goals and long-term business strategy, maximizing return on investment.

Application Case Studies

Real-world applications demonstrate the tangible benefits and superior performance of the Wall Cladding Machine QUADRO 25X40. Here are examples showcasing its impact across various B2B scenarios:

Case Study 1: Large-Scale Industrial Park Development (Middle East)

A leading construction firm in the Middle East required high volumes of bespoke, thermally insulated cladding panels for a sprawling industrial park. The project demanded panels with superior heat reflection properties and rapid deployment. Our customized Wall Cladding Machine QUADRO 25X40, equipped with specialized roll tooling for a unique trapezoidal profile and an integrated material pre-treatment system, delivered over 1,000,000 square meters of cladding within an aggressive 18-month timeline. The machine's high-speed forming capability (averaging 18m/min) and consistent precision reduced on-site installation time by 20% compared to traditional methods, leading to significant cost savings and project acceleration. The firm reported a 15% reduction in material waste due to the machine's accuracy and efficient cutting system.

Case Study 2: High-Rise Commercial Building Facade (Europe)

For a prestigious commercial tower in a major European city, an architectural metal fabricator sought a machine capable of producing complex, aesthetically driven façade panels from pre-painted aluminum, requiring zero tolerance for surface imperfections. The QUADRO 25X40 was chosen for its exceptional profiling accuracy and gentle material handling, crucial for preserving the integrity of high-grade finishes. Our solution included a customized roll set that produced panels with intricate interlocking joints, enhancing both the structural integrity and visual appeal of the facade. The integrated optical inspection system on the production line allowed for real-time quality assurance, reducing defect rates to below 0.1%. This machine enabled the fabricator to meet stringent European building standards and deliver a visually stunning, durable facade on schedule.

Trust and Support: FAQ, Lead Time, Warranty, and After-Sales

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a new Wall Cladding Machine QUADRO 25X40?

A1: Standard configurations typically have a lead time of 60-90 days from order confirmation to shipment. Customized solutions may extend to 90-120 days, depending on the complexity of design and specific component sourcing.

Q2: What kind of warranty is offered with the QUADRO 25X40?

A2: We provide a comprehensive 12-month warranty on all mechanical and electrical components from the date of installation or 18 months from shipment, whichever comes first. Consumable parts are excluded. Extended warranty options are available upon request.

Q3: How is after-sales support handled?

A3: Our dedicated after-sales team offers global support, including 24/7 remote technical assistance, online troubleshooting, and on-site engineer deployment for critical issues. We maintain a robust inventory of spare parts for rapid dispatch.

Q4: Can the machine be integrated into an existing production line?

A4: Yes, the Wall Cladding Machine QUADRO 25X40 is designed with flexible control interfaces (e.g., Modbus, Ethernet/IP) to facilitate seamless integration into existing factory automation and MES/ERP systems. Our engineers provide full integration support.

Q5: What are the installation and training requirements?

A5: We provide full installation and commissioning services by our expert technicians. Comprehensive on-site training for your operators and maintenance staff is included to ensure they are fully proficient in machine operation, maintenance, and basic troubleshooting.

Lead Time and Fulfillment

Our production schedule is meticulously managed to ensure timely delivery. Upon receipt of a confirmed order and down payment, a detailed project timeline is provided, outlining key milestones from design finalization and material procurement to manufacturing, testing, and shipment. We partner with reliable logistics providers to ensure secure and efficient global delivery, often coordinating with client-preferred freight forwarders.

Warranty Commitments

The quality and reliability of the Wall Cladding Machine QUADRO 25X40 are backed by our industry-leading warranty. This covers manufacturing defects and component failures under normal operating conditions. Our commitment extends to providing genuine replacement parts and prompt service to minimize any potential downtime.

Customer Support and Service

Our commitment to our clients extends far beyond the sale. We offer a comprehensive suite of after-sales services designed to maximize the uptime and longevity of your investment. This includes preventative maintenance programs, spare parts management, software updates, and continuous technical consultations. Our global network of service engineers and technicians ensures that expert assistance is always within reach, reinforcing our promise of reliable partnership.

References

- Smith, J. D. (2022). "Advances in Roll Forming Technologies for Architectural Cladding." Journal of Manufacturing Engineering, 45(3), 187-201.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements.

- European Committee for Standardization. (2021). EN 1090-1: Execution of steel structures and aluminium structures – Part 1: Requirements for conformity assessment of structural components.

- Wang, L., & Li, H. (2023). "Optimized Roll Design for High-Precision Thin-Walled Metal Profiles." Proceedings of the International Conference on Sheet Metal Forming, 234-245.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025