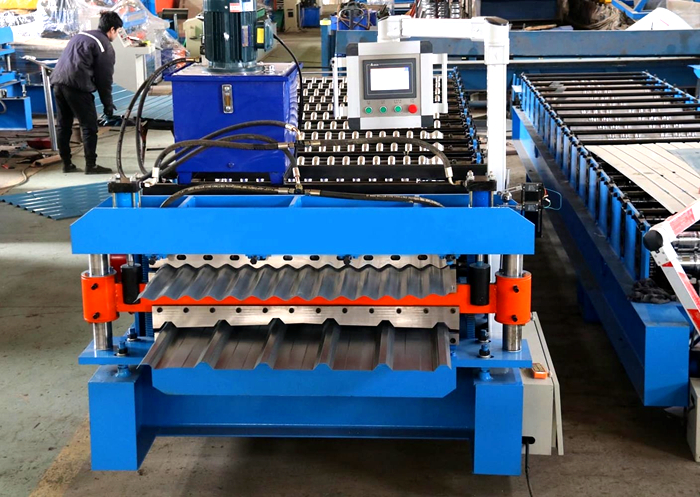

Versatile Light Steel Roll Forming Machines for Custom Construction Solutions and Efficient Production

Custom Light Steel Roll Forming Machine Revolutionizing Construction and Manufacturing

In the realm of modern construction and manufacturing, efficiency and precision are paramount. The advent of custom light steel roll forming machines has transformed the way structural components are produced, enhancing both the speed and quality of construction projects. These machines are at the forefront of the industrial revolution, paving the way for innovative applications in various sectors, including residential buildings, commercial complexes, and industrial facilities.

Understanding Light Steel Roll Forming

Light steel roll forming is a process that involves shaping steel into desired profiles through a series of rollers. This technique allows manufacturers to create high-strength yet lightweight materials that are essential for modern architectural designs. The versatility of roll forming makes it an ideal choice for producing components such as C, Z, U, and L-shaped sections, which can be used in framing, roofing, and cladding.

The custom aspect of these machines is particularly noteworthy. Every construction project has unique requirements, and custom light steel roll forming machines can be tailored to produce specific profiles based on those needs. This means that businesses can create bespoke solutions that fit their design parameters, thereby avoiding the limitations of pre-fabricated materials.

Key Benefits of Custom Light Steel Roll Forming Machines

1. Cost Efficiency One of the main advantages of custom roll forming machines is their cost-effectiveness. By producing components in-house, manufacturers can significantly reduce material waste, labor costs, and lead times. This efficiency translates into lower overall project costs, making it an attractive option for contractors.

2. Durability and Strength Light steel is known for its remarkable strength-to-weight ratio, making it a preferred choice in construction. The roll forming process enhances the material's durability, ensuring that structures are built to withstand various environmental stresses, such as wind and seismic activity.

custom light steel roll forming machine

3. Customization Flexibility Custom machines can accommodate different thicknesses, widths, and lengths of steel, allowing for unprecedented flexibility in design. As architects and engineers push the boundaries of creativity, the ability to produce unique profiles on demand is invaluable.

4. Streamlined Production The automation involved in custom light steel roll forming machines accelerates the manufacturing process. With high-speed operations, businesses can increase output without compromising quality, making it easier to meet tight project deadlines.

5. Sustainability As the construction industry moves towards more sustainable practices, light steel offers a recyclable option. Roll forming minimizes waste and promotes the efficient use of materials, aligning with the eco-friendly goals that many companies now prioritize.

Applications in the Industry

Custom light steel roll forming machines are employed across a variety of industries. In residential construction, they facilitate the quick assembly of framing systems, leading to faster project completions. For commercial developments, these machines are integral in producing metal roofing and siding systems that are both functional and aesthetically appealing. Moreover, in the manufacturing sector, they support the production of components used in machinery and storage systems.

Conclusion

The rise of custom light steel roll forming machines marks a significant advancement in the construction and manufacturing landscape. By combining efficiency, durability, and flexibility, these machines cater to the evolving demands of modern architecture while promoting sustainable practices. As industries continue to embrace innovative technologies, the impact of custom light steel roll forming will undoubtedly shape the future of structural engineering, allowing for the creation of buildings that are not only strong and efficient but also uniquely tailored to meet specific needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025