Understanding the Process of Corrugated Roll Forming Machinery in Metal Fabrication

The Evolution and Importance of Corrugated Roll Forming Machines

In the realm of manufacturing, the demand for efficient and versatile production methods has led to significant advancements in technology. One such innovation is the corrugated roll forming machine, a vital piece of equipment that has revolutionized the production of corrugated sheets and panels. This article explores the capabilities, applications, and importance of corrugated roll forming machines in today’s industrial landscape.

Understanding Corrugated Roll Forming Machines

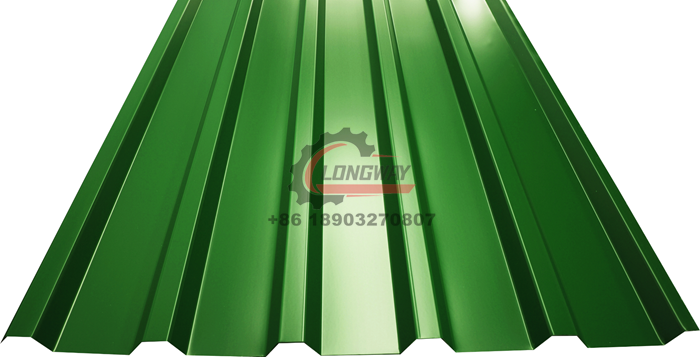

Corrugated roll forming machines are specialized devices designed to produce corrugated sheets from various metals, including steel, aluminum, and copper. These machines utilize a series of rollers to shape metal strips into a series of waves or ridges, creating a lightweight, yet strong, corrugated profile. The process of roll forming is continuously efficient and suitable for high-volume production, making it a favored choice among manufacturers.

The design of corrugated roll forming machines often features adjustable roller configurations, allowing producers to create a wide range of profiles to meet specific application requirements. Additionally, many modern machines are equipped with advanced technology, such as computerized controls, which enhance precision and reduce the likelihood of human error in the production process.

Applications Across Industries

The versatility of corrugated roll forming machines finds utility in various industries. One of the primary sectors benefiting from this technology is the construction industry. Corrugated sheets are utilized for roofing, wall cladding, and paneling due to their strength, durability, and resistance to weather conditions. These sheets offer superior insulation properties and can effectively reduce energy costs for buildings.

Additionally, the packaging industry employs corrugated materials extensively. Corrugated cardboard boxes, made from sheets manufactured by roll forming machines, provide robust protection for goods during shipping and handling. The lightweight nature of these boxes also helps reduce transportation costs, making corrugated packaging a cost-effective solution for businesses.

corrugated roll forming machine

The automotive industry is another significant user of corrugated roll forming technology, where it is utilized in manufacturing parts like chassis components and structural elements due to their lightweight and high-strength qualities.

Benefits of Using Corrugated Roll Forming Machines

The use of corrugated roll forming machines brings numerous advantages to manufacturers. Firstly, the efficiency of the roll forming process minimizes material waste, contributing to more sustainable practices. As the machine continuously operates, it produces uniform products with minimal discrepancies, ensuring that each piece meets quality standards without the need for extensive rework.

Moreover, these machines enable rapid production rates, making them ideal for large-scale manufacturing operations. Businesses can respond quickly to market demands without sacrificing quality, thus providing a competitive edge.

In addition to productivity benefits, corrosion-resistant materials can be utilized in the production of corrugated products, extending the lifespan of various applications. This durability translates to lower maintenance costs over time, further enhancing the value proposition for manufacturers and consumers alike.

Conclusion

In summary, corrugated roll forming machines are at the forefront of modern manufacturing, offering efficient and reliable solutions for producing corrugated materials across various industries. Their ability to create high-quality products rapidly while minimizing waste and costs underscores their importance in an increasingly competitive market. As technology continues to advance, we can expect further innovations in the capabilities of these machines, reinforcing their critical role in the manufacturing landscape. Whether for construction, packaging, or automotive applications, the impact of corrugated roll forming machines is profound, shaping the way materials are produced and utilized in our daily lives.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025