Understanding the Cost Factors of Metal Roofing Machine Production and Factory Pricing

Costs of Metal Roofing Machines A Comprehensive Overview

In recent years, the popularity of metal roofing has surged, driven by its durability, energy efficiency, and aesthetic appeal. As a result, the demand for metal roofing machines has increased significantly. Whether you’re a manufacturer, a contractor, or an entrepreneur looking to invest in this booming market, understanding the costs associated with metal roofing machines is essential.

Initial Investment

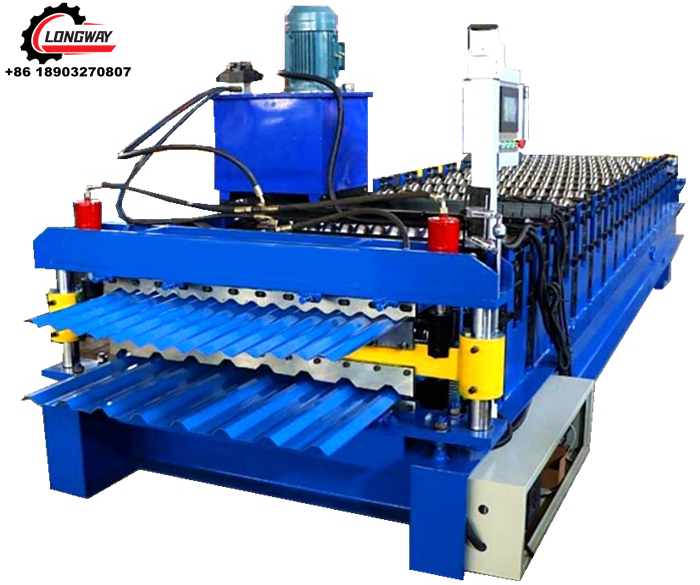

When considering investing in a metal roofing machine, the initial investment is one of the largest factors to account for. The cost of these machines can vary dramatically based on their type, features, and production capacity. On average, a small to medium-sized metal roofing machine may range from $20,000 to $100,000. Higher-end models, which can produce roofing panels at a larger scale, may exceed $200,000.

Factors influencing the price include the technology used, the materials from which the machine is built, and its operational capabilities. For instance, machines that offer advanced automation and integrated software for design and monitoring may command higher prices but offer better efficiency and productivity in return.

Operational Costs

In addition to the upfront costs, potential buyers should also consider operational costs associated with running metal roofing machines. These costs include electricity consumption, labor, maintenance, and repair expenses. Depending on the complexity and efficiency of the machine, operational costs can add up significantly over time.

Electricity costs can vary based on the machine's power requirements and local energy prices. Additionally, labor is a crucial component, as skilled operators are necessary to ensure efficient production and maintenance. If the machine requires specialized training to operate, factor in those training costs as well.

metal roofing machine cost factory

Material Costs

The quality of the end product can greatly depend on the materials used in the production process. Steel, aluminum, copper, or zinc can all be used for metal roofing, and each comes with its own cost implications. The prices of these raw materials fluctuate based on market demand, supplier contracts, and current economic conditions. As a manufacturer, purchasing materials in bulk can often lead to better pricing. However, it is essential to maintain a balance between securing quality materials and managing expenses effectively.

Maintenance & Longevity

Investing in a high-quality metal roofing machine can result in long-term savings. Machines built from durable materials and backed by reliable manufacturers often require less frequent maintenance. Regular upkeep will prevent costly repairs and extend the machine's lifespan, leading to a better return on investment.

Consider buying from manufacturers that provide comprehensive warranties and customer support. This not only ensures that you have assistance in case of any operational issues but also reflects the manufacturer's confidence in their machines.

Conclusion

In conclusion, while the upfront costs of purchasing a metal roofing machine may seem daunting, it's essential to consider the potential return on investment. The durability, energy efficiency, and aesthetic benefits of metal roofing create a growing market, making it a lucrative investment for manufacturers and contractors alike. Additionally, factors such as operational costs, material prices, and maintenance requirements play a significant role in the overall financial picture. Therefore, conducting thorough research and analyzing your specific needs will help you make an informed decision, paving the way for a successful venture in the metal roofing industry. Investing wisely will position you well within this ever-evolving market.