u channel roll forming machine manufacturer

Understanding U Channel Roll Forming Machines A Comprehensive Overview

In the world of metal fabrication, precision and efficiency are paramount. One of the most integral machines that caters to these needs is the U channel roll forming machine. This machinery specifically produces U-shaped channels, which are widely used in various industries, including construction, automotive, and manufacturing. As a U channel roll forming machine manufacturer, it is essential to understand the features, capabilities, and advantages of these machines.

What is a U Channel Roll Forming Machine?

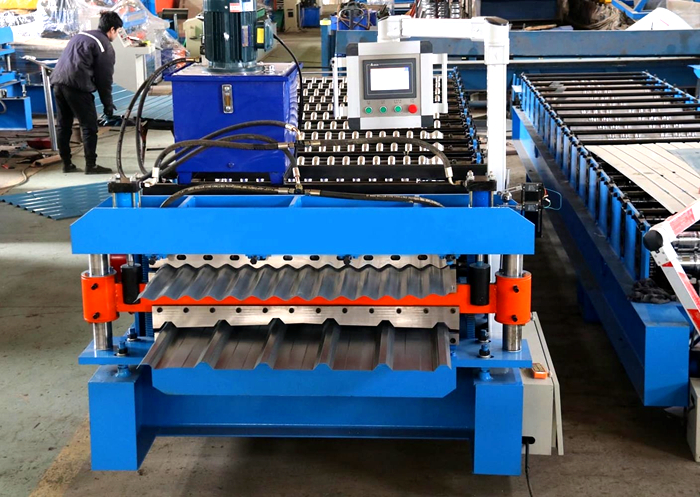

A U channel roll forming machine is a specialized equipment designed to convert metal sheets into U-shaped profiles through a continuous bending process. This machine works by feeding flat metal strips through a series of rollers that gradually shape the metal into the desired U channel form. The process is known for its ability to produce long lengths of uniform cross-sectional profiles with high precision, which is crucial for maintaining structural integrity in construction and fabrication projects.

Key Features and Components

1. Roller Setup The heart of any roll forming machine is its set of rollers. Each roller is meticulously designed to shape the metal progressively into the U channel profile. The number of rollers can vary depending on the thickness of the material and the complexity of the profile.

2. Material Feed System The feeding mechanism ensures that the metal strips are fed into the rollers at a consistent speed and alignment. This is critical for producing high-quality U channels without any deformations.

3. Cutting and Punching Stations Most U channel roll forming machines come equipped with cutting modules that can trim the U channels to the desired lengths. Some models also include punching stations that create holes or slots in the U channels for easier assembly and integration into various applications.

4. Control System Modern machines are equipped with advanced digital control systems allowing operators to precisely adjust the parameters for speed, pressure, and cutting lengths. This automation enhances productivity and minimizes the risk of human error.

u channel roll forming machine manufacturer

Benefits of Using U Channel Roll Forming Machines

1. High Efficiency The roll forming process enables the production of U channels at a rapid pace, making it ideal for high-volume manufacturing. Once set up, the machine can continuously produce profiles without substantial downtime.

2. Cost-effectiveness The automation capability of these machines leads to a reduction in labor costs. Additionally, the precision of the production process minimizes material wastage, enhancing overall profitability.

3. Versatility U channel roll forming machines can handle a variety of materials, including steel, aluminum, and other metals. This versatility makes them suitable for different applications and industrial sectors.

4. Customization Manufacturers can configure the machinery to create U channels of various sizes and specifications, allowing customization based on specific project requirements.

5. Durability and Reliability Investing in a U channel roll forming machine from a reputable manufacturer ensures that you receive a robust and reliable piece of equipment that can withstand heavy workloads while maintaining accuracy.

Conclusion

The demand for U channel profiles in various industries continues to grow, making U channel roll forming machines an essential component in modern manufacturing. As a U channel roll forming machine manufacturer, understanding the intricacies of the technology, including its components, features, and operational benefits, will enable you to deliver high-quality machinery that meets the evolving needs of the industry. By offering precision, efficiency, and customization, these machines play a crucial role in shaping the future of metal fabrication.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025