Different Categories of Roll Forming Machines for Various Applications

Types of Roll Forming Machines An Overview

Roll forming is a sophisticated manufacturing process used to create long lengths of metal components with a uniform cross-section. This process utilizes a series of rollers to bend and shape metal sheets or strips into desired profiles without cutting or welding the material. The efficiency and accuracy of roll forming make it a popular choice in industries such as automotive, construction, and HVAC. Understanding the different types of roll forming machines is crucial for businesses looking to optimize their production processes.

1. Standard Roll Forming Machines

The most common type of roll forming machine is the standard roll former. This machine consists of a series of rollers arranged in a specific sequence. The metal strip is fed through these rollers to produce a continuous profile. Standard roll forming machines are versatile and can produce a wide range of shapes, including channels, angles, and Z-sections. They are often used to manufacture products such as metal studs, roofing panels, and trim.

2. High-Speed Roll Forming Machines

As industries demand faster production rates, high-speed roll forming machines have been developed. These machines can operate at significantly higher speeds than standard models, often exceeding 100 feet per minute. High-speed roll forming machines are equipped with advanced technology, including servo drives and automated controls, which enhance their efficiency and precision. They are ideal for producing high volumes of parts, particularly in the automotive sector for components like door frames and structural members.

3. Custom Roll Forming Machines

Custom roll forming machines are designed to meet specific customer requirements. These machines can be configured to produce unique shapes and sizes that standard machines cannot accommodate. Manufacturers often invest in custom roll forming solutions to create niche products or to differentiate themselves in the market. The customization can include specific roll designs, tooling, and conveyor systems tailored to the production layout.

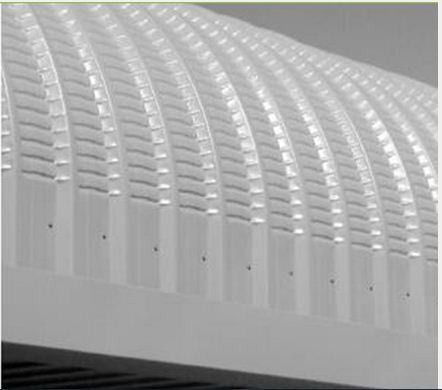

types of roll forming machine

4. Twin-Screw Roll Forming Machines

Twin-screw roll forming machines are a relatively new innovation in the market. They utilize two parallel screws to feed the metal strip through the forming rollers, allowing for increased stability and control during the shaping process. This type of machine is particularly beneficial for producing complex profiles with tight tolerances and can handle a wide range of materials, including thin-gauge metals and advanced alloys. Twin-screw machines are often employed in the aerospace and high-tech manufacturing sectors due to their precision.

5. Automated Roll Forming Lines

Automated roll forming lines integrate roll forming machines with other manufacturing processes, such as cutting, welding, and assembly. These lines utilize robotics and sophisticated software to streamline production, reduce labor costs, and minimize errors. Automated systems can significantly enhance productivity, making them an attractive option for manufacturers looking to scale their operations. These lines are commonly used in sectors that require both precision and speed, such as prefabricated construction components.

6. Portable Roll Forming Machines

For applications that require on-site bending and shaping of materials, portable roll forming machines have become increasingly popular. These machines are compact, lightweight, and designed for easy setup in various locations. They allow contractors to form metal sheets directly at construction sites, which can save time and reduce waste. Portable roll forming machines are particularly useful for small-scale projects or temporary installations.

Conclusion

The roll forming industry continues to evolve, offering various machine types tailored to specific production needs. Whether opting for standard machines, high-speed variations, custom solutions, or automated systems, understanding the capabilities and applications of each type can help manufacturers make informed decisions. As technology advances, the efficiency and versatility of roll forming machines are likely to improve further, enhancing their role in modern manufacturing processes. Selecting the right type of roll forming machine is vital for optimizing production, maintaining quality, and meeting customer demands in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025