types of roll forming machine

Types of Roll Forming Machines An Overview

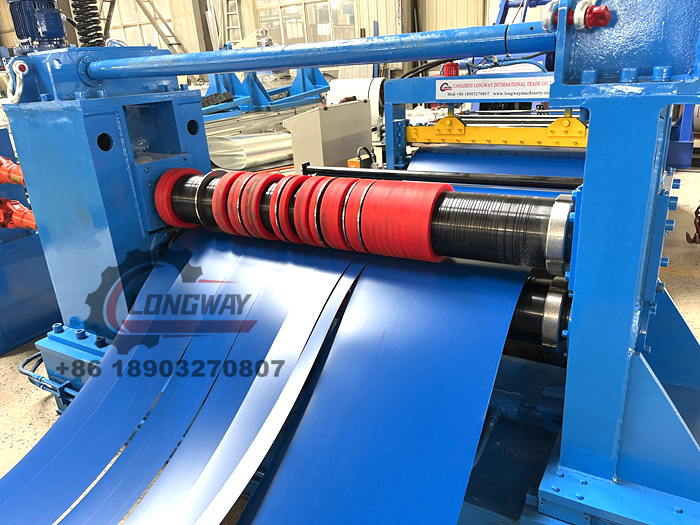

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, is passed through consecutive sets of rolls to progressively shape it into the desired cross-section. This process is highly efficient and is widely used in various industries such as automotive, construction, and manufacturing. Understanding the different types of roll forming machines can help businesses choose the right equipment for their specific needs.

1. Standard Roll Forming Machines

Standard roll forming machines are the most common type used in the industry. They feature a series of rollers that shape the material into a predetermined profile. These machines are typically equipped with adjustable stands for controlling the height and spacing of the rollers, allowing for various profiles to be formed with relative ease. The flexibility of standard roll forming machines makes them suitable for producing parts like metal studs, tracks, and other structural components.

2. Heavy-Duty Roll Forming Machines

For applications requiring the shaping of thicker materials, heavy-duty roll forming machines are essential. These machines are built with stronger frames and more robust rollers to accommodate higher loads and provide greater durability. They are capable of forming metals with thicknesses ranging from 8 gauge to thicker, depending on the material. Heavy-duty machines are typically used in the production of structural steel components, automotive parts, and other heavy-duty applications.

3. High-Speed Roll Forming Machines

High-speed roll forming machines focus on maximizing production efficiency. These machines are designed to operate at higher speeds without sacrificing product quality. They often include advanced features such as automated entry and exit systems, quick-change setups for different profiles, and precision controls to ensure consistency. High-speed roll forming is ideal for high-volume production runs where time and efficiency are critical, such as in the manufacture of roofing, wall panels, and automotive components.

types of roll forming machine

4. Technology-Integrated Roll Forming Machines

With advancements in technology, many modern roll forming machines now incorporate digital controls and automation. These technology-integrated machines often come equipped with sensors and feedback systems that monitor and adjust the forming process in real time. This integration ensures the highest levels of precision and minimizes material waste. Additionally, some machines feature programmable logic controllers (PLCs) that allow operators to easily switch between different profiles with minimal downtime. These smart systems are revolutionizing the way roll forming is done, making it easier to produce complex shapes and designs.

5. Portable Roll Forming Machines

Another unique category of roll forming machines is the portable type. These machines are designed for on-site construction and repair work, allowing for flexible manufacturing of components in remote locations. Portable roll forming machines are typically lighter in weight and easier to transport compared to standard machines. They can produce items such as standing seam roofing, gutter systems, and architectural trim, making them a valuable asset for contractors.

6. Custom Roll Forming Machines

For businesses requiring bespoke solutions, custom roll forming machines can be designed and built to specific specifications. These machines can be engineered to create unique shapes and complex profiles that may not be achievable with standard machines. Custom machines are ideal for specialized industries where standard profiles are insufficient, offering manufacturers the ability to innovate and diversify their product offerings.

Conclusion

The variety of roll forming machines available today allows manufacturers to select the most suitable options based on their production needs, material types, and desired geometries. From standard and heavy-duty machines to high-speed and technology-integrated options, each type has its unique features and advantages. As technology continues to evolve, the roll forming industry is poised to see further innovations that will enhance efficiency, reduce costs, and improve product quality. By choosing the correct roll forming machine, businesses can optimize their operations and meet the demands of a competitive market. Whether for bulk manufacturing or custom applications, understanding the types of roll forming machines is essential for success in this dynamic sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025