Truss Roll Forming Machine Manufacturers and Their Innovative Solutions for Construction Industry

Understanding Truss Roll Forming Machine Factories

In the modern era of construction and manufacturing, the efficiency and precision of creating structural components play a crucial role in ensuring the strength and reliability of various constructions. One such critical machine that facilitates these processes is the truss roll forming machine. Factories specializing in truss roll forming machines have become essential for industries looking to optimize their capabilities in producing truss systems for buildings, bridges, and various frameworks.

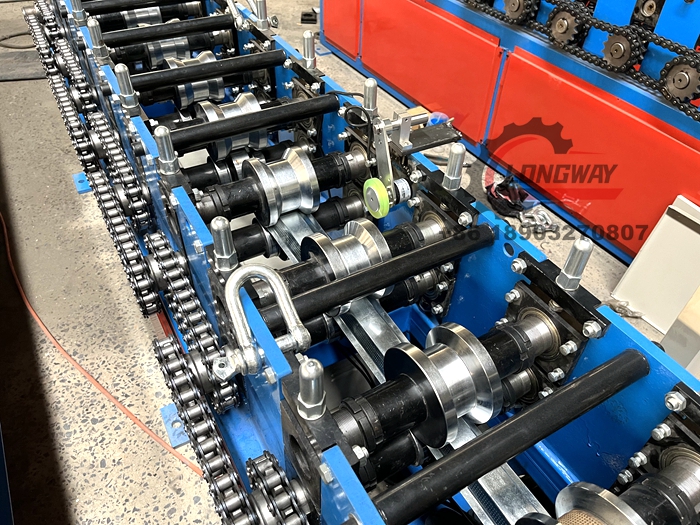

Truss roll forming machines are designed to create high-quality truss components from metal sheets. These machines utilize advanced roll forming technology, where metal strips are passed through a series of rollers to achieve the desired shape and thickness. The versatility of truss roll forming machines allows them to produce various designs and sizes tailored to specific project requirements, making them indispensable in architectural and structural engineering.

One of the primary advantages of sourcing truss roll forming machines from specialized factories is the ability to leverage cutting-edge technology. Many manufacturers incorporate automation and computerized control systems into their machines, which enhances precision and reduces manual labor. This technological advancement leads to faster production rates and mitigates the risk of human error, further ensuring the structural integrity of the trusses produced.

truss roll forming machine factories

Moreover, factories that focus on truss roll forming machine manufacturing often emphasize quality control and testing. By adhering to strict quality standards, they ensure that every machine produced meets the necessary safety and durability requirements. This commitment to quality is vital, as trusses support significant weight and must withstand various environmental factors.

When selecting a truss roll forming machine factory, potential buyers should also consider the range of services offered. Many manufacturers provide not only the machines but also comprehensive after-sales support, including installation, training, and maintenance. This service-oriented approach helps customers maximize their investment and ensures the longevity and performance of the equipment.

Additionally, sustainability has become an increasingly important factor in manufacturing. Factories are adopting eco-friendly practices by optimizing material usage and energy consumption during the production of truss roll forming machines. This trend not only reduces waste and lowers production costs but also appeals to environmentally-conscious customers seeking sustainable building solutions.

In conclusion, truss roll forming machine factories play a pivotal role in the construction and manufacturing sectors. By offering advanced technology, rigorous quality control, and comprehensive support services, these factories enable companies to efficiently produce robust truss systems essential for various structural applications. As the demand for innovative building solutions continues to rise, the importance of investing in reliable truss roll forming machines from reputable factories will undoubtedly remain significant.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025