Jun . 15, 2024 21:51

Back to list

Trim to length, line manufacturer.

Cut to Length Line Manufacturer A Comprehensive Guide

In the world of manufacturing, precision and efficiency are paramount. One aspect that often requires meticulous attention is cutting materials to specific lengths. This is where a cut to length line manufacturer comes into play, offering a range of services to ensure that raw materials are transformed into the desired dimensions with accuracy and speed.

What is a Cut to Length Line?

A cut to length line, also known as a slitting line, is a fully automated system designed to process metal coils or sheets. It consists of several key components, including uncoilers, slitting reels, cutting machines, and recoilers. The primary function of this line is to slit large rolls of material into smaller, predetermined widths, which can then be used in various manufacturing processes.

Why Choose a Cut to Length Line Manufacturer?

There are several reasons why businesses choose to work with a specialized cut to length line manufacturer. Firstly, these manufacturers have extensive experience in designing and installing custom-built lines that meet the unique requirements of each client. They understand the importance of precision and efficiency and strive to deliver top-quality results.

Secondly, working with a cut to length line manufacturer ensures that you receive ongoing support and maintenance for your equipment. These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance

These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance cut to lenght line manufacturer.

Thirdly, a reputable cut to length line manufacturer will have a proven track record of success in the industry. They will have worked with a wide range of clients across various industries and can provide references and case studies to demonstrate their capabilities.

Key Features of a High-Quality Cut to Length Line

When selecting a cut to length line, it's important to consider several key features that can impact its performance and reliability. These include

* Uncoiler capacity The uncoiler should be capable of handling large coils of material, ensuring that production runs are not interrupted by inadequate coil capacity.

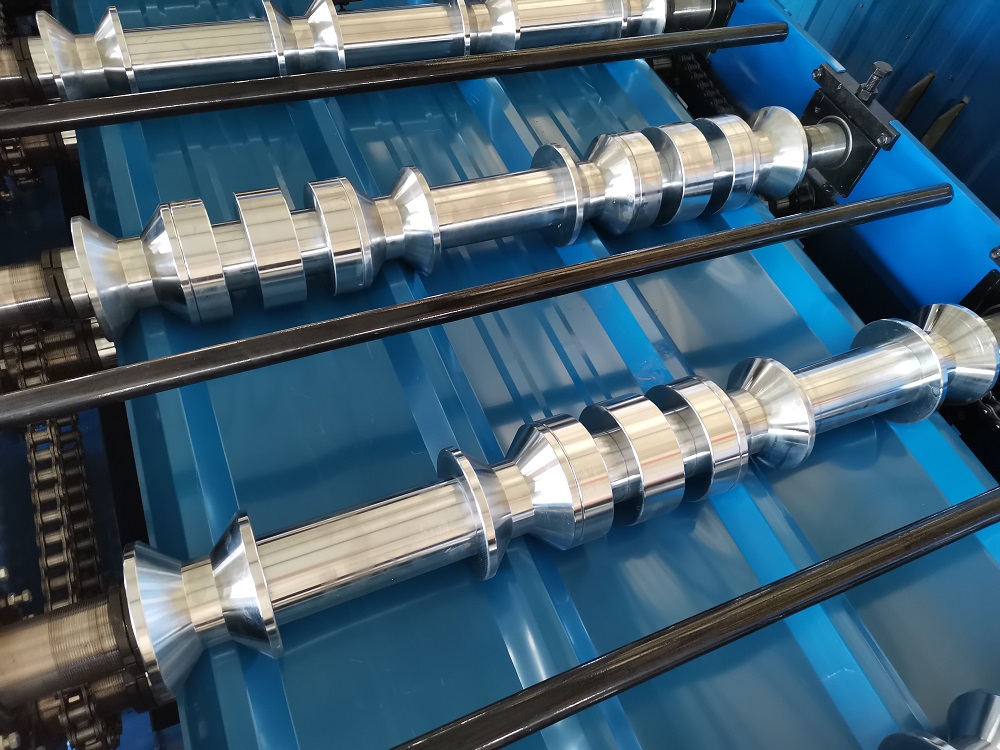

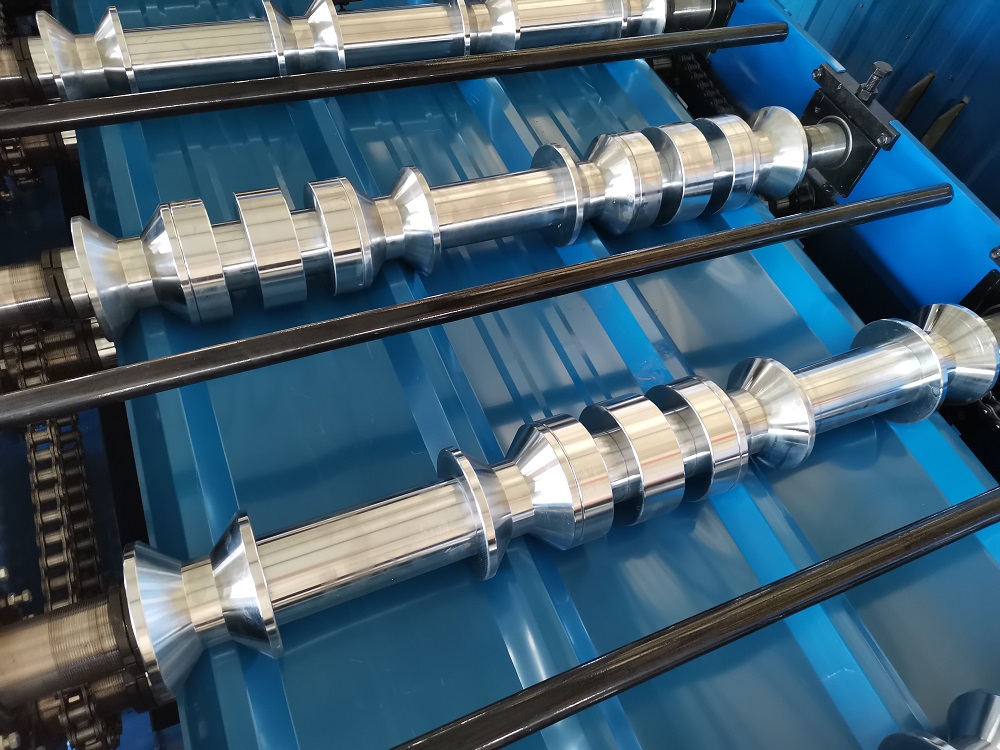

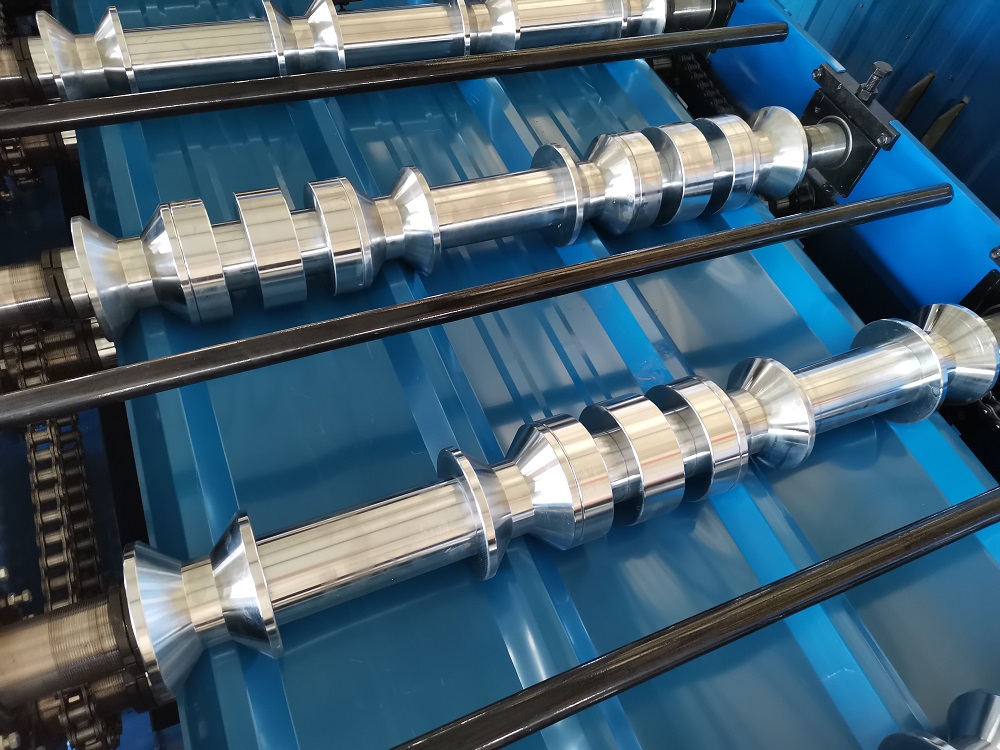

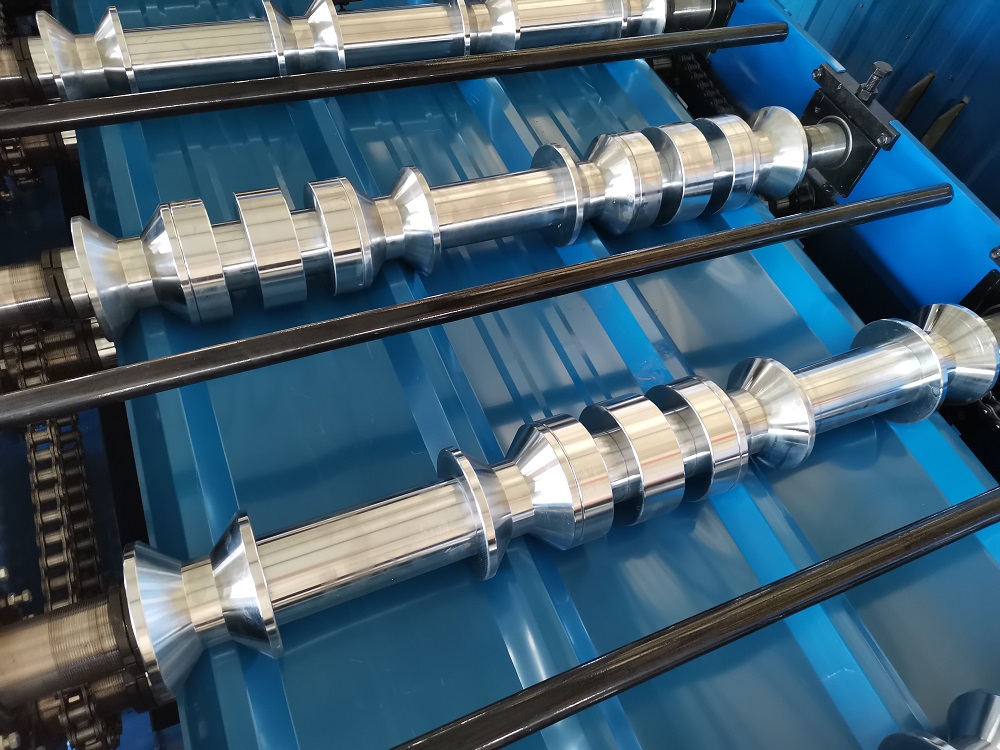

* Slitting accuracy The slitting reel should be equipped with precision bearings and knives to ensure that the material is cut to the correct width and without burrs or distortions.

* Cutting speed The cutting machine should be capable of processing materials at high speeds, reducing downtime and increasing productivity.

* Recoiler tension control The recoiler should be equipped with advanced tension control systems to ensure that the slit material is wound onto the drum evenly and without wrinkles or creases.

In conclusion, a cut to length line manufacturer plays a crucial role in the manufacturing process by providing precision cutting services that help businesses achieve their goals. By choosing a reputable manufacturer with a proven track record of success, businesses can ensure that they receive high-quality equipment and ongoing support to keep their operations running smoothly.

cut to lenght line manufacturer.

Thirdly, a reputable cut to length line manufacturer will have a proven track record of success in the industry. They will have worked with a wide range of clients across various industries and can provide references and case studies to demonstrate their capabilities.

Key Features of a High-Quality Cut to Length Line

When selecting a cut to length line, it's important to consider several key features that can impact its performance and reliability. These include

* Uncoiler capacity The uncoiler should be capable of handling large coils of material, ensuring that production runs are not interrupted by inadequate coil capacity.

* Slitting accuracy The slitting reel should be equipped with precision bearings and knives to ensure that the material is cut to the correct width and without burrs or distortions.

* Cutting speed The cutting machine should be capable of processing materials at high speeds, reducing downtime and increasing productivity.

* Recoiler tension control The recoiler should be equipped with advanced tension control systems to ensure that the slit material is wound onto the drum evenly and without wrinkles or creases.

In conclusion, a cut to length line manufacturer plays a crucial role in the manufacturing process by providing precision cutting services that help businesses achieve their goals. By choosing a reputable manufacturer with a proven track record of success, businesses can ensure that they receive high-quality equipment and ongoing support to keep their operations running smoothly.

These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance

These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance These manufacturers typically offer comprehensive warranties and service contracts to ensure that your line continues to operate at peak performance cut to lenght line manufacturer.

Thirdly, a reputable cut to length line manufacturer will have a proven track record of success in the industry. They will have worked with a wide range of clients across various industries and can provide references and case studies to demonstrate their capabilities.

Key Features of a High-Quality Cut to Length Line

When selecting a cut to length line, it's important to consider several key features that can impact its performance and reliability. These include

* Uncoiler capacity The uncoiler should be capable of handling large coils of material, ensuring that production runs are not interrupted by inadequate coil capacity.

* Slitting accuracy The slitting reel should be equipped with precision bearings and knives to ensure that the material is cut to the correct width and without burrs or distortions.

* Cutting speed The cutting machine should be capable of processing materials at high speeds, reducing downtime and increasing productivity.

* Recoiler tension control The recoiler should be equipped with advanced tension control systems to ensure that the slit material is wound onto the drum evenly and without wrinkles or creases.

In conclusion, a cut to length line manufacturer plays a crucial role in the manufacturing process by providing precision cutting services that help businesses achieve their goals. By choosing a reputable manufacturer with a proven track record of success, businesses can ensure that they receive high-quality equipment and ongoing support to keep their operations running smoothly.

cut to lenght line manufacturer.

Thirdly, a reputable cut to length line manufacturer will have a proven track record of success in the industry. They will have worked with a wide range of clients across various industries and can provide references and case studies to demonstrate their capabilities.

Key Features of a High-Quality Cut to Length Line

When selecting a cut to length line, it's important to consider several key features that can impact its performance and reliability. These include

* Uncoiler capacity The uncoiler should be capable of handling large coils of material, ensuring that production runs are not interrupted by inadequate coil capacity.

* Slitting accuracy The slitting reel should be equipped with precision bearings and knives to ensure that the material is cut to the correct width and without burrs or distortions.

* Cutting speed The cutting machine should be capable of processing materials at high speeds, reducing downtime and increasing productivity.

* Recoiler tension control The recoiler should be equipped with advanced tension control systems to ensure that the slit material is wound onto the drum evenly and without wrinkles or creases.

In conclusion, a cut to length line manufacturer plays a crucial role in the manufacturing process by providing precision cutting services that help businesses achieve their goals. By choosing a reputable manufacturer with a proven track record of success, businesses can ensure that they receive high-quality equipment and ongoing support to keep their operations running smoothly. Latest news

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025

Related Products