trapezoidal sheet roll forming machine manufacturer

Understanding Trapezoidal Sheet Roll Forming Machines A Comprehensive Overview

In the world of manufacturing and construction, the preciseness and efficiency of materials play a vital role. One such innovative method that has gained prominence is the trapezoidal sheet roll forming process. This technique is primarily employed in the production of trapezoidal sheets, which are widely used in roofing, cladding, and various other structural applications. This article delves into the role of trapezoidal sheet roll forming machines in modern manufacturing, their benefits, operational mechanics, and the factors to consider when choosing a manufacturer.

What is a Trapezoidal Sheet Roll Forming Machine?

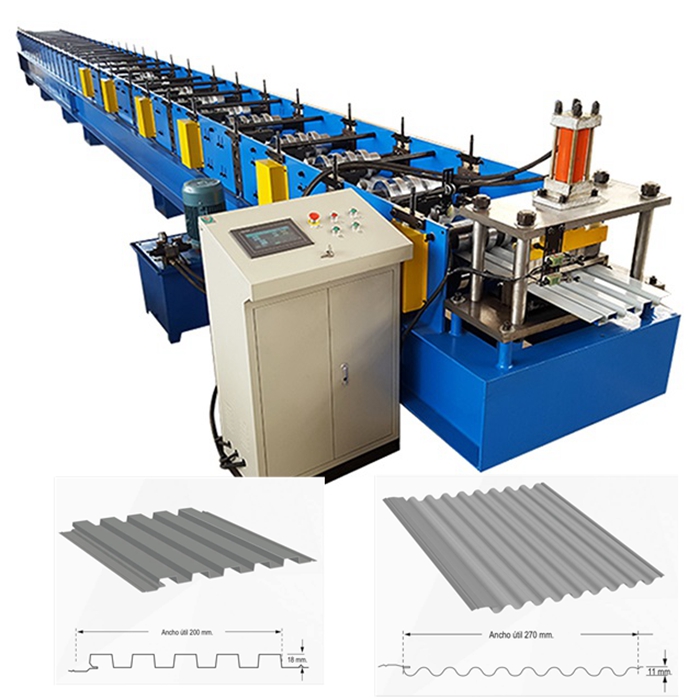

A trapezoidal sheet roll forming machine is a specialized piece of equipment designed to continuously shape metal sheets into trapezoidal profiles. These machines work by feeding a flat metal sheet through a series of rollers, which gradually bend and shape the material into the desired trapezoidal form. The formed sheets are robust, lightweight, and exhibit excellent durability, making them ideal for construction projects.

Benefits of Using Trapezoidal Sheets

One of the primary advantages of trapezoidal sheets is their structural integrity. The trapezoidal shape offers enhanced strength and load-bearing capabilities compared to flat sheets. Additionally, these sheets are highly efficient in terms of water drainage, which is crucial for roofing applications where water retention can lead to leaks and structural damage. The design minimizes the risk of rust and degradation over time, thereby ensuring longevity and reducing maintenance costs.

Furthermore, trapezoidal sheets play a significant role in improving energy efficiency. Their design allows for better thermal insulation, which can lead to lower energy consumption in buildings. The aesthetic appeal of these sheets also adds to their popularity, as they come in various colors and finishes, enhancing the overall architectural design.

The Operational Mechanics of Roll Forming

Roll forming is a continuous bending process that utilizes multiple pairs of rollers to shape the metal sheet. When the flat metal is fed into the machine, it passes through a sequence of rollers that progressively create the trapezoidal profile. The process is not only efficient but also allows for high-volume production with minimal waste.

Moreover, trapezoidal sheet roll forming machines can be configured with additional features such as automatic cutting systems and digital controls to enhance precision and efficiency. These features ensure that manufacturers can produce sheets to exact specifications, accommodating different thicknesses and raw materials.

trapezoidal sheet roll forming machine manufacturer

Choosing the Right Manufacturer

Selecting a reputable trapezoidal sheet roll forming machine manufacturer is paramount for ensuring quality production. Here are several factors to consider

1. Experience and Reputation Look for manufacturers with a wealth of experience in the industry. Established companies are typically more reliable and have proven track records of producing durable and efficient machinery.

2. Customization Options Not all manufacturing needs are the same. A good manufacturer should offer customization options to tailor the machinery according to specific production requirements.

3. Technology and Innovation Opt for manufacturers that utilize the latest technology in their machines. Advanced features such as automation, real-time monitoring, and energy efficiency can significantly enhance production capabilities.

4. Customer Support and Maintenance Services A manufacturer that provides robust after-sales support and maintenance services is essential. This ensures that your machinery operates optimally over its lifespan.

5. Warranty and Quality Assurance Before making a purchase, check the warranty offered on the machine. A strong warranty indicates the manufacturer's confidence in their product quality.

Conclusion

The trapezoidal sheet roll forming machine is an indispensable asset in modern manufacturing environments, especially within the construction industry. Its ability to produce high-quality trapezoidal sheets makes it a preferred choice among builders and architects. By understanding the advantages of these machines and the factors to consider when selecting a manufacturer, businesses can leverage the potential of trapezoidal sheets for enhanced structural solutions. As technology advances, the future of roll forming looks promising, paving the way for even more efficient and innovative manufacturing processes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025