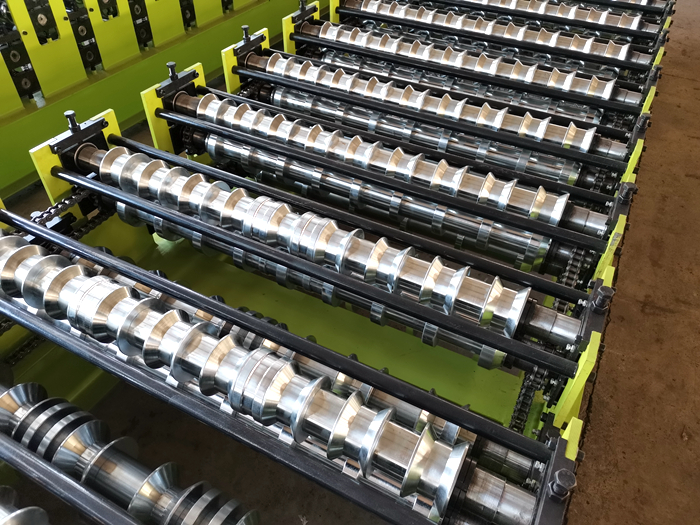

trapezoidal sheet roll forming machine factory

Trapezoidal Sheet Roll Forming Machine A Key Player in Modern Manufacturing

In the realm of modern manufacturing, the trapezoidal sheet roll forming machine has emerged as a vital tool for producing high-quality metal sheets. This innovative machinery optimizes production processes across various industries, delivering efficiency and precision that meets the demands of contemporary construction and manufacturing sectors.

The trapezoidal sheet roll forming machine operates by converting flat metal sheets into trapezoidal profiles through a series of precise, sequential forming steps. These machines utilize advanced technologies, ensuring that the end products exhibit uniform dimensions and impressive strength. As construction and architectural demands evolve, trapezoidal sheets have gained popularity due to their versatility, durability, and aesthetic appeal, making them ideal for roofing, wall cladding, and a variety of structural applications.

One of the key advantages of the trapezoidal sheet roll forming machine lies in its efficiency. With the ability to produce large quantities of sheets in a relatively short period, manufacturers can meet tight deadlines while maintaining high production quality. The automated nature of these machines minimizes human error and labor costs, allowing businesses to improve their overall operational efficiency.

Moreover, the flexibility of trapezoidal sheet roll forming machines enables manufacturers to customize products. These machines can be tailored to produce sheets of varying thicknesses, lengths, and profiles according to specific project requirements. This adaptability is particularly beneficial in industries where bespoke solutions are often needed, such as construction, automotive, and appliances.

trapezoidal sheet roll forming machine factory

In addition to customization and efficiency, the use of trapezoidal sheet roll forming machines contributes to sustainability. Many manufacturers focus on recycled metals as raw materials, thereby reducing environmental impact. The efficient use of materials during production also minimizes waste, aligning with global efforts to promote green manufacturing practices.

The durability of products created by trapezoidal sheet roll forming machines is another significant benefit. Trapezoidal sheets are known for their strength and resistance to weather conditions, making them suitable for both commercial and residential applications. As a result, they play a crucial role in enhancing the longevity and performance of structures in which they are used.

Furthermore, the global demand for trapezoidal sheets has been on the rise, driven by progress in infrastructure development and urbanization. This trend has led to increased investments in roll forming technology, fostering innovation and competitiveness among manufacturers. As more businesses recognize the potential of trapezoidal sheet roll forming machines, the industry is likely to see continuous advancements in machine design and capabilities, further elevating production standards.

In conclusion, the trapezoidal sheet roll forming machine is a fundamental asset in the manufacturing landscape. Its ability to deliver high-quality products efficiently and sustainably positions it as an essential equipment for businesses aiming to thrive in an ever-evolving market. As technology progresses, the role of these machines will undoubtedly expand, paving the way for new possibilities in metal sheet production and application.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025