trapezoidal roll forming machine company

Understanding Trapezoidal Roll Forming Machines A Comprehensive Overview

In the world of manufacturing, efficiency and precision are fundamental. Among the various technologies that facilitate these goals, trapezoidal roll forming machines have emerged as a crucial tool for producing high-quality metal components. This article will delve into the significance of trapezoidal roll forming machines, their applications, operational principles, and the advantages they offer to manufacturers.

What is a Trapezoidal Roll Forming Machine?

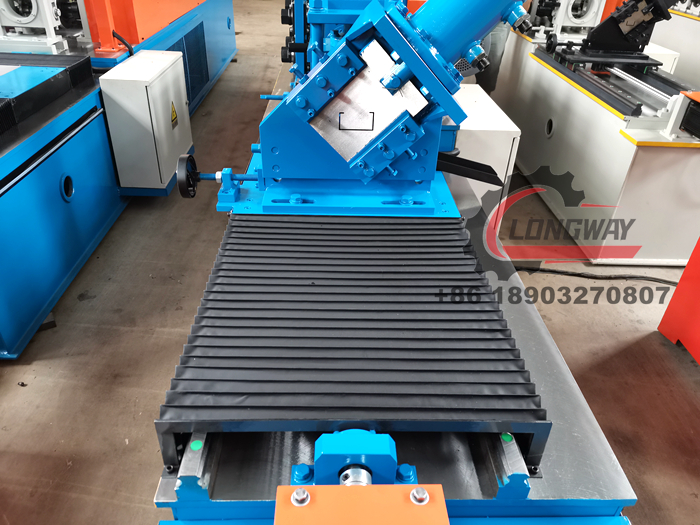

A trapezoidal roll forming machine is specifically designed to produce trapezoidal profiles from metal sheets. These profiles are commonly used in roofing, wall cladding, and other structural applications due to their strength and durability. The machine utilizes a continuous bending process where flat metal stock is fed through a series of rollers that progressively shape the material into the desired trapezoidal cross-section.

The Operational Process

The operation of a trapezoidal roll forming machine starts with the selection of the appropriate metal sheet, often made of materials such as pre-painted steel, aluminum, or galvanized steel. The process typically involves the following steps

1. Feed Mechanism The metal sheet is fed into the machine, where it is aligned to ensure accurate forming. Proper alignment is crucial for maintaining the consistency of the profile.

2. Roll Forming As the metal sheet passes through a sequence of rollers, each roller performs a specific bending operation. The configuration of the rollers is meticulously designed to produce the desired trapezoidal shape. This sequence of bending reduces the material's thickness and generates the final profile.

3. Cutting Once the desired length is achieved, the formed trapezoidal section is cut to size. This is typically done using a precise cutting mechanism that ensures clean cuts without damaging the profile.

4. Quality Inspection To guarantee that the finished product meets the required specifications, a quality inspection is performed. This can include checks on dimensions, surface quality, and structural integrity.

Applications of Trapezoidal Profiles

Trapezoidal profiles produced by roll forming machines find wide application across various industries. They are primarily utilized in

trapezoidal roll forming machine company

- Construction Trapezoidal sheets are commonly used for roofing and wall cladding in industrial and commercial buildings, providing excellent strength and weather resistance. - Signage The durability and aesthetic appeal of trapezoidal profiles make them ideal for producing outdoor signage. - Transportation The automotive and aerospace industries use trapezoidal profiles in various components to enhance structural integrity while minimizing weight.

- HVAC Systems Trapezoidal shapes are often utilized in ductwork and other HVAC components due to their efficient airflow properties.

Advantages of Using Trapezoidal Roll Forming Machines

Investing in a trapezoidal roll forming machine brings several advantages

- High Production Speed The continuous nature of the roll forming process allows for rapid production rates, making it a time-efficient solution for manufacturers.

- Material Efficiency The process minimizes material waste, as the design can be optimized to reduce scrap during production.

- Consistency and Precision Roll forming delivers uniform and precise profiles, ensuring that all produced components meet strict quality standards.

- Versatility These machines can be configured to create various profiles beyond trapezoidal shapes, showcasing their adaptability to different manufacturing needs.

- Cost-effectiveness With reduced labor costs and lower material waste, trapezoidal roll forming can significantly lower production costs.

Conclusion

Trapezoidal roll forming machines are valuable assets in modern manufacturing, providing efficient, precise, and adaptable solutions for producing trapezoidal profiles. Their wide range of applications, coupled with numerous advantages, positions them as a desirable option for industries involved in construction, signage, transportation, and beyond. As manufacturing technology continues to evolve, the importance of roll forming machinery in enhancing production capabilities cannot be overstated. Companies investing in this technology are well-equipped to meet the growing demands of the market while ensuring high-quality standards in their products.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025