Top Manufacturers of Wall Panel Roll Forming Machines for High-Quality Construction Solutions

The Importance of Wall Panel Roll Forming Machines An Overview of Manufacturers and Their Innovations

In the modern construction industry, the demand for high-quality wall panels has escalated due to an increasing emphasis on aesthetic appeal, energy efficiency, and structural integrity. This is where wall panel roll forming machines come into play. These machines are vital in manufacturing wall panels that provide both functionality and visual charm to buildings. As the market for such machines grows, various manufacturers have emerged, each contributing innovations to optimize production processes.

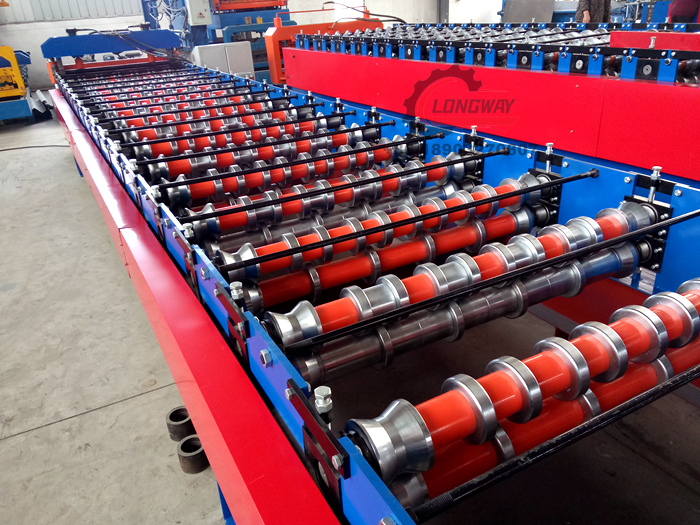

Wall panel roll forming machines are engineered to convert flat metal sheets into finished panels through a series of rolling and forming processes. The equipment typically operates by feeding a coil of metal into a series of rollers, which shape the metal according to desired specifications. This continuous process allows for high-volume production while maintaining consistency in quality. Significant manufacturers in this sector have invested heavily in technology to enhance the precision and efficiency of their machines.

One of the primary advantages of using roll forming technology for wall panels is the reduction in waste. Traditional manufacturing methods often involve cutting metal sheets, which can create surplus material. In contrast, roll forming minimizes excess material through its continuous nature. Furthermore, modern roll forming machines are designed with adjustable settings that can accommodate varying panel designs, making them versatile tools for manufacturers.

Leading manufacturers in the wall panel roll forming machine market often focus on integrating advanced technologies such as automation and artificial intelligence. For instance, some machines come equipped with automatic feeding systems and computerized controls, which allow for quick adjustments to production setups. This level of automation not only streamlines operations but also significantly reduces labor costs and human error, providing a consistent output of high-quality panels.

wall panel roll forming machine manufacturers

Sustainability is another critical focus for modern manufacturers. As the construction industry moves towards greener practices, companies are looking to roll forming machines that can utilize recycled materials. Manufacturers are developing machines that can handle different types of metals, including aluminum and steel, which can be sourced sustainably. With environmental considerations becoming a priority, this capability not only appeals to eco-conscious businesses but also aligns with global efforts to reduce carbon footprints.

In addition to addressing sustainability, manufacturers are also recognizing the importance of customization. Customers often seek unique designs that can distinguish their buildings from competitors. Consequently, wall panel roll forming machine manufacturers are developing systems that allow for greater design flexibility, enabling clients to create panels with various shapes, textures, and finishes. This adaptability enhances the creative possibilities for architects and builders alike.

Another aspect that manufacturers are capitalizing on is the integration of smart technology into their machines. The advent of Industry 4.0 has seen manufacturers incorporating IoT capabilities into their roll forming systems. This integration allows for real-time monitoring of machinery performance and production data analysis, leading to improved efficiency and predictive maintenance. Manufacturers that embrace these advancements can offer superior products while reducing downtime and optimizing operational costs.

In conclusion, wall panel roll forming machines play an essential role in the construction industry, and the continuous innovations from various manufacturers are shaping the future of building materials. With a focus on sustainability, customization, automation, and smart technology, these manufacturers are not only meeting the current demands of the industry but are also paving the way for its future. As the market evolves, it will be exciting to see how these advancements influence construction methods and the overall landscape of building design.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025