Top Manufacturers of Roof Tile Production Equipment and Their Key Features for Quality Production

The Importance of Roof Tile Making Machines An Overview of Manufacturers

The roofing industry plays a crucial role in construction, with roof tiles being an essential product providing structural integrity and aesthetic appeal to buildings. The demand for high-quality roof tiles has led to the emergence of a specialized segment within the manufacturing sector roof tile making machines. As the global construction market continues to grow, many manufacturers are focusing on producing advanced roof tile making machines to meet this rising demand.

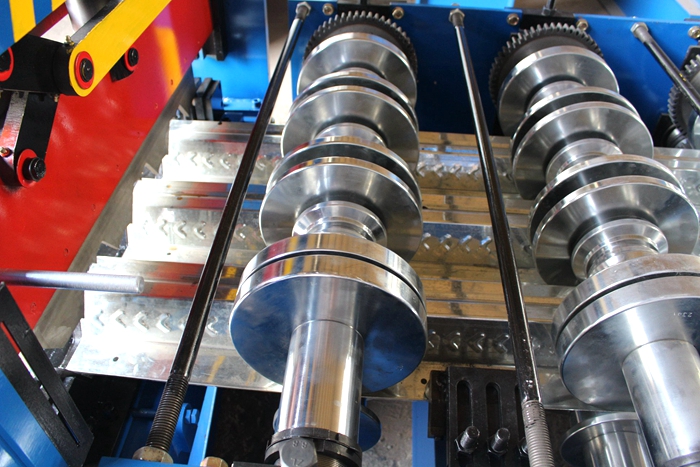

Roof tile making machines come in various types, designed to produce different styles of tiles, including ceramic, concrete, and even lightweight options. These machines automate the production process, increasing efficiency and reducing labor costs. Manufacturers have invested significantly in research and development to enhance the capabilities of these machines, incorporating advanced technologies to improve productivity and quality control.

One of the key advantages of modern roof tile making machines is their ability to produce tiles with uniform dimensions and quality. Precision engineering ensures that the final product meets established standards, which is critical for installation and longevity. Moreover, many manufacturers offer machines that can produce multiple types of tiles in a single setup, allowing businesses to adapt to changing market demands without significant capital investment.

Prominent manufacturers in this sector have established themselves by focusing on quality, innovation, and customer service. Companies such as XYZ Machinery and ABC Tile Solutions are recognized for their state-of-the-art machines that incorporate automation and robotics. These manufacturers not only produce the machines but also provide comprehensive training and support to ensure their clients can maximize efficiency. This post-purchase service has become an essential aspect of the customer experience, solidifying long-term partnerships.

roof tile making machine manufacturers

The choice of materials is significant in the roof tile making process, and leading manufacturers have developed machines capable of working with a wide range of raw materials. For instance, concrete roof tiles are made using a mixture of sand, cement, and water. The ability of a machine to effectively mix, mold, and cure these materials is vital for producing high-quality tiles. Additionally, innovative features such as energy efficiency and reduced waste generation are increasingly becoming selling points for manufacturers looking to appeal to environmentally-conscious buyers.

In recent years, advancements in technology have also brought about improvements in the energy efficiency of roof tile making machines. Manufacturers are exploring ways to minimize energy consumption during production and utilizing renewable energy sources wherever possible. This shift not only benefits the environment but also reduces operational costs for businesses in the long term.

Globalization has also influenced the roof tile making machine manufacturing industry. Manufacturers are increasingly exporting their machines to emerging markets, where there is a growing demand for building materials. This trend has led to the establishment of global supply chains and collaborative efforts between manufacturers and local companies to ensure that the machines are tailored to meet regional needs.

As the construction industry evolves, the role of roof tile making machines is expected to expand. With the rise of smart technology, the integration of Internet of Things (IoT) capabilities and machine learning could revolutionize how these machines operate. This will allow for real-time monitoring, predictive maintenance, and optimization of production schedules, further elevating the efficiency of manufacturing processes.

In conclusion, as the market for roof tiles continues to expand, the demand for high-quality roof tile making machines is set to rise. Manufacturers that prioritize innovation, quality, and customer support will likely thrive in this competitive landscape. The future of roofing materials is undoubtedly intertwined with the advancements in machinery, positioning these manufacturers at the forefront of the construction industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025