Top Manufacturers of Rolling Shutter Slats Roll Forming Machines for Enhanced Security Solutions

Exploring the Role of Rolling Shutter Slats Roll Forming Machine Companies in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, the significance of specialized machinery cannot be overstated. Among these crucial machines are rolling shutter slats roll forming machines, which play an essential role in producing high-quality shutter slats. These machines are vital for constructing rolling shutters, widely used in commercial and industrial buildings for security and protection. As the demand for efficient and high-quality shutters grows, so does the importance of companies dedicated to the design and production of rolling shutter slats roll forming machines.

A rolling shutter serves multiple purposes, acting as a barrier against theft and vandalism, while also providing insulation and aesthetic appeal to buildings. The components of rolling shutters must meet stringent quality standards to ensure durability and reliability. This is where roll forming machines come into play. These machines utilize advanced technologies to shape metal sheets into slats with precision, enabling the production of strong, lightweight shutters that can withstand various environmental conditions.

Companies specializing in rolling shutter slats roll forming machines are at the forefront of this technology. They employ skilled engineers and cutting-edge design software to create machines that optimize the roll forming process. The efficiency of these machines is paramount, as manufacturers seek to balance speed with high-quality output. By refining the roll forming process, these companies help manufacturers reduce waste, lower production costs, and enhance product quality.

One of the key aspects that rolling shutter slats roll forming machine companies focus on is customization. Each rolling shutter project may require different specifications, such as size, thickness, and coating. Companies that offer customizable machines can cater to the unique needs of their clients, allowing for a more flexible manufacturing process. This adaptability is a significant competitive advantage in today's dynamic market.

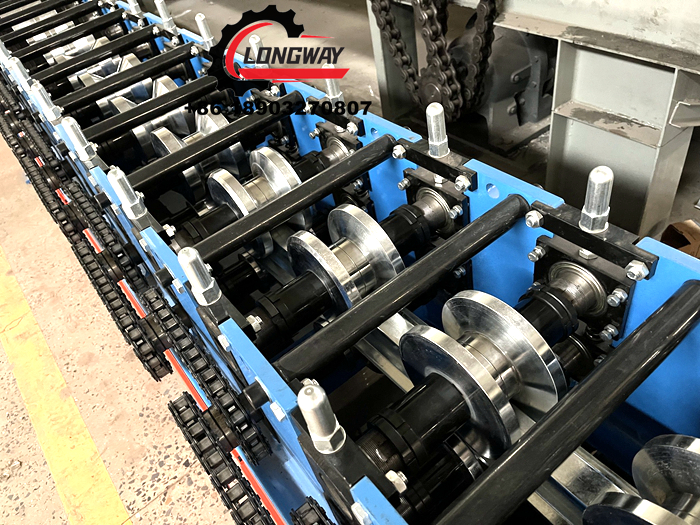

rolling shutter slats roll forming machine company

Moreover, these machine manufacturers are increasingly integrating automation and smart technologies into their machines. By leveraging Industry 4.0 principles, such as IoT (Internet of Things) connectivity and data analytics, rolling shutter slats roll forming machines can monitor production conditions in real-time. This allows for predictive maintenance and quality control, which enhances the overall efficiency and reliability of the production process.

In addition to technological advancements, sustainability is an increasingly important focus for companies in this sector. As businesses and consumers become more environmentally conscious, manufacturers are seeking machines that not only produce high-quality products but also minimize energy consumption and waste. Companies that emphasize eco-friendly practices in their manufacturing processes can attract discerning clients looking to meet their sustainability goals.

The global market for rolling shutter slats roll forming machines continues to expand, driven by growing urbanization, burgeoning infrastructure projects, and heightened security concerns. This creates ample opportunities for machine manufacturers to innovate and grow. By continuously improving machine performance and expanding their offerings, these companies can play a pivotal role in shaping the future of the construction and security industries.

In conclusion, rolling shutter slats roll forming machine companies are integral to the modern manufacturing landscape. Their commitment to quality, customization, automation, and sustainability positions them as key players in the production of reliable and efficient rolling shutters. As the industry evolves, these companies will continue to drive innovation, ensuring that manufacturers have access to the best tools needed to meet the demands of a rapidly changing world.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025