Top Manufacturers of Purlin Making Machines for Efficient Steel Fabrication Solutions

Purlin Making Machine Companies Revolutionizing the Steel Industry

In the modern construction landscape, the demand for efficient, robust, and cost-effective steel structures is rising at an unprecedented rate. This has propelled the growth of purlin making machine companies, which play a crucial role in producing one of the key components of steel buildings—purlins. Purlins, which are horizontal members that support the roof and walls of a structure, are essential for maintaining structural integrity, especially in commercial and industrial buildings.

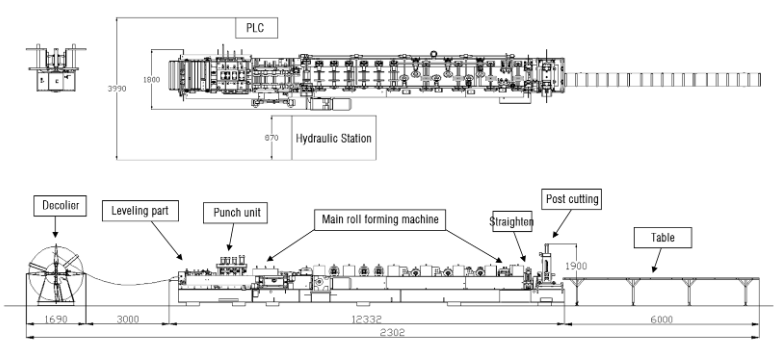

Purlin making machines are specifically designed to fabricate these components from steel, offering flexibility, precision, and high production rates. These machines use cold-formed steel to create C and Z-shaped purlins, which are widely recognized for their strength and weight advantages. The global shift towards economical building solutions has spurred numerous businesses to invest in purlin production machinery, leading to a burgeoning industry.

Key Players in the Market

Numerous companies worldwide manufacture purlin making machines, each offering a unique set of features and technologies. Leading manufacturers often focus on integrating advanced automation and control systems that enhance operational efficiency. For instance, companies such as M/s. K. S. Purlin Machines, Decoiler, and Roll Forming Machine Manufacturer have made significant strides in optimizing their machines for high-speed production and reducing material waste.

These manufacturers also prioritize the quality of materials used in their machines, ensuring durability and long-term performance. By utilizing advanced steel processing technologies, they can produce machines that withstand rigorous working conditions while delivering exceptional output. Additionally, many manufacturers offer customization options to cater to specific client requirements, reflecting the growing trend towards personalized manufacturing solutions.

Technological Advancements

purlin making machine companies

The evolution of purlin making machines has been heavily influenced by advancements in technology. Automation and computerization have transformed traditional manufacturing processes, enabling greater precision and reducing labor costs. State-of-the-art purlin making machines are now equipped with CNC (Computer Numerical Control) technology, allowing for intricate designs and quick setup changes. This technological leap significantly enhances production capabilities, allowing manufacturers to respond rapidly to changing market demands.

Moreover, integration of robotics in the manufacturing process has led to increased efficiency. Automated systems can handle tasks such as loading, cutting, and packaging, minimizing the risk of human error and optimizing workflow. The rise of Industry 4.0 also sees manufacturers leveraging data analytics and the Internet of Things (IoT) to monitor equipment performance and predict maintenance needs, resulting in reduced downtime and operational costs.

Market Trends

As green building initiatives gain traction, there is a concerted effort within the industry to minimize environmental impact. Purlin making machine companies are responding by developing machines that can utilize recycled materials, thus promoting sustainability. Furthermore, energy-efficient machinery is becoming increasingly popular, appealing to manufacturers looking to reduce operational costs while adhering to environmental regulations.

Additionally, the localization of production is emerging as a trend, with companies establishing manufacturing facilities closer to their target markets. This strategy not only reduces shipping costs but also allows for faster service delivery and greater customer satisfaction.

Conclusion

Purlin making machine companies are at the forefront of modern construction technology, facilitating the production of essential structural components with efficiency and precision. As the industry continues to evolve, driven by technological advancements and sustainability efforts, these companies are poised to play a critical role in shaping the future of steel construction. By focusing on innovation and quality, they are helping to meet the growing demands of the global construction market, ensuring that buildings are not only strong and durable but also sustainable and cost-effective.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025