Top Manufacturers of Omega Roll Forming Machines for Precision Metal Fabrication Needs

Omega Roll Forming Machine Manufacturers Understanding the Industry

In the world of industrial manufacturing, roll forming has become a pivotal process for creating a variety of metal products. Among the various types of roll forming machines, omega roll forming machines stand out due to their ability to produce omega-shaped profiles commonly used in construction, automotive, and HVAC applications. This article delves into the significance of omega roll forming machine manufacturers, their offerings, and the future of this vital machinery in the industry.

What is Omega Roll Forming?

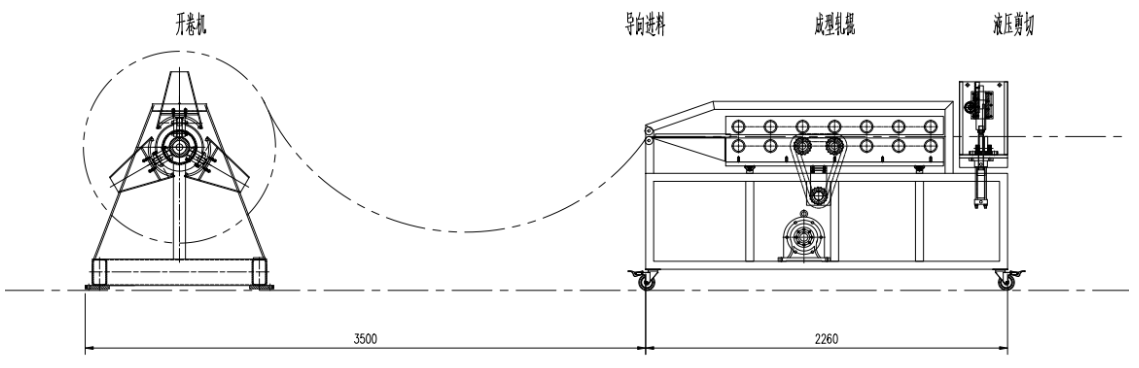

Omega roll forming is a specific type of metal forming that uses a series of rollers to gradually shape a flat strip of metal into an omega profile. This process is primarily used for crafting metal components with a consistent cross-section and intricate shapes. The omega profile is recognized for its high structural integrity and excellent load-bearing capabilities, making it ideal for various applications, such as wall studs, channels, and roof trusses.

The Role of Manufacturers

Omega roll forming machine manufacturers play a crucial role in designing and producing these specialized machines. They are responsible for integrating advanced technologies into their equipment to enhance productivity, efficiency, and precision. These manufacturers offer a wide range of machines tailored for different industrial needs, ensuring that customers can select systems that best fit their production requirements. Key features that distinguish top manufacturers include robust engineering, customization options, automation capabilities, and user-friendly interfaces.

Features and Innovations

Modern omega roll forming machines come equipped with various innovative features. Some of the prominent attributes include

1. Customization Manufacturers often provide customized solutions that cater to specific product requirements, ensuring that clients receive machines tailored to their unique production needs.

omega roll forming machine manufacturers

3. Energy Efficiency Many manufacturers are emphasizing energy-efficient designs, which reduce the overall operation costs while contributing to environmental sustainability.

4. Durability and Maintenance High-quality materials and engineering practices are incorporated to enhance the durability of the machines. Manufacturers also provide maintenance support to ensure the longevity of their products.

5. Safety Features Given the nature of metalworking, safety is paramount. Leading manufacturers incorporate safety enhancements in their designs, such as emergency stop buttons, guards to prevent accidents, and safety sensors.

Market Trends and Future Prospects

The demand for omega roll forming machines is on the rise as industries increasingly recognize the advantages of using omega profiles. The ongoing expansion of the construction sector, along with the growing need for sustainable building solutions, is driving this demand. As manufacturers adapt to the evolving market landscape, they are also exploring the use of digital technologies such as Industry 4.0 solutions. This encompasses IoT integrations for real-time data analytics and machine learning applications for predictive maintenance.

Moreover, as sustainability becomes a dominant theme in manufacturing, omega roll forming machine manufacturers are likely to prioritize eco-friendly materials and processes in their production lines. This shift will not only align with global sustainability goals but also enhance the marketability of their products.

Conclusion

In summary, omega roll forming machine manufacturers are crucial players in the industrial landscape, offering innovative machines that meet the diverse needs of various sectors. With continuous advancements in technology and a growing focus on sustainability, these manufacturers are poised to enhance their offerings, thereby shaping the future of metal forming processes. As industries evolve, the role of these manufacturers will remain vital in driving productivity, efficiency, and quality in metalworking applications worldwide.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025