Top Manufacturers of Downspout Elbow Machinery for Efficient Rainwater Management Solutions

Understanding Downspout Elbow Machine Manufacturers

In the world of manufacturing, the demand for efficient and specialized machinery is ever-growing. One such niche is in the production of downspout elbows, which are essential components in rainwater drainage systems. Downspout elbows are fittings that direct rainwater from a vertical downspout into horizontal drainage pipes or directly onto the ground. The precision of these components significantly affects the overall functionality of a rainwater management system. This brings us to the importance of downspout elbow machine manufacturers.

The Role of Downspout Elbow Machines

Downspout elbow machines are specialized pieces of equipment designed to create the curved shapes necessary for downspout elbows. These machines are engineered for precision, speed, and efficiency, enabling manufacturers to produce large quantities of elbows without compromising on quality. Modern machines can handle various materials such as aluminum, steel, and plastic, accommodating the demands of different construction jobs and applications.

The process typically involves cutting, bending, and shaping the raw material to produce finished elbows that fit seamlessly into downspout systems. Sophisticated machinery can automate many of these steps, minimizing labor costs and reducing the likelihood of human error. This is crucial in maintaining the high standards of quality that customers expect, especially in residential and commercial projects where proper drainage is vital.

Features of Modern Downspout Elbow Machines

Contemporary downspout elbow machines come equipped with several advanced features. Some notable attributes include

1. Automation Many modern machines are fully automated, allowing for continuous production without the need for constant supervision. This leads to increased output and reduced operational costs. 2. Precision Engineering These machines utilize advanced technology, such as CNC (Computer Numerical Control) systems, to ensure accuracy in every piece produced. This is essential for ensuring that elbows fit tightly and securely into existing drainage systems. 3. Versatility They can often be adjusted to produce various sizes and shapes of elbows, catering to different construction specifications and customer demands.

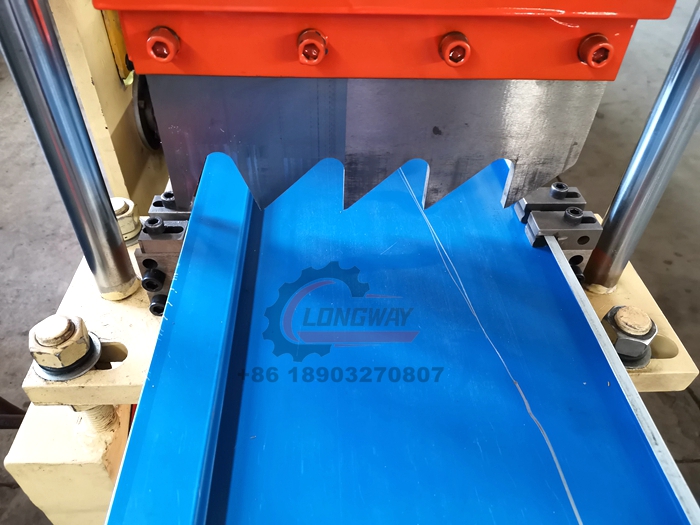

downspout elbow machine manufacturers

4. Safety Features Manufacturers are placing greater emphasis on the safety of their machinery. Modern machines often include safety guards, emergency stop buttons, and user-friendly interfaces to protect operators.

The Market for Downspout Elbow Machines

The market for downspout elbow machine manufacturers is diverse and competitive, with companies ranging from small enterprises to large corporations. The choice of manufacturer often depends on factors like reputation, technological capability, and customer service. Manufacturers that offer customization options tend to attract a more extensive customer base, as they can cater to specific requirements for various construction projects.

Moreover, the growing trend of DIY home improvement projects has also created a demand for smaller, more affordable machines that individuals or small contractors can use. This segment of the market is particularly interesting, as it combines technology with user accessibility.

Conclusion

In summary, downspout elbow machine manufacturers play a crucial role in the construction and plumbing industries by providing the tools needed to produce vital drainage components. As technology continues to evolve, these manufacturers are likely to enhance their offerings, focusing on automation, precision, and sustainability. Whether for large-scale commercial applications or small DIY projects, the importance of reliable, high-quality downspout elbow machines cannot be overstated, as they are key to effective rainwater management systems that protect our buildings and environment.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025