Top Manufacturers of 6% Half Round Gutter Machines for Efficient Rainwater Management Solutions

The Importance of Half Round Gutter Machines A Focus on 6% Manufacturers

In the ever-evolving world of construction, efficient and effective water drainage systems are crucial for preserving the structural integrity of buildings and enhancing their longevity. Among the various components of the drainage systems, gutters play a vital role. Half round gutters, known for their aesthetic appeal and functionality, have gained immense popularity in recent years. To meet the demand for these systems, manufacturers have developed specialized machines for producing half round gutters, with a particular focus on the efficiency and capabilities offered by a 6% improvement in manufacturing output.

Understanding Half Round Gutters

Half round gutters, as their name suggests, are semi-circular channels that efficiently direct rainwater away from a building's roof and foundation. Unlike traditional square or rectangular gutters, half round systems feature smooth curves that allow for better water flow, minimizing the risk of clogs and facilitating easier maintenance. Their stylish appearance not only enhances the architectural appeal of a building, but they can also be seamlessly integrated into various design aesthetics, from classic to modern.

The Role of Manufacturing Machines

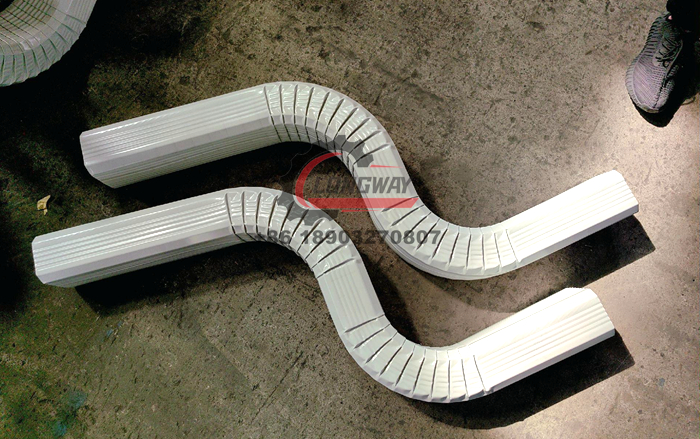

To produce half round gutters, manufacturers depend on advanced machinery that can handle various materials such as aluminum, steel, copper, and vinyl. The processes involved in crafting these gutters necessitate precision and consistency to ensure that each piece meets required standards for functionality and durability. This is where specialized half round gutter machines come into play.

6 half round gutter machine manufacturers

These machines are engineered to perform tasks such as rolling, cutting, and forming the material into the desired gutter shape. The integration of technology has allowed for improvements in production speed and quality control, leading to a more efficient manufacturing process. A specific focus on enhancing production capacity by 6%—whether through improved automation, optimized material handling, or refined operational processes—can lead to significant benefits for manufacturers.

Advantages of 6% Improvement in Manufacturing

Increasing the production efficiency of half round gutter machines by just 6% can have substantial impacts on the manufacturing industry. Firstly, this improvement can lead to higher output rates, allowing companies to meet growing market demands without compromising on quality. As construction projects become more frequent and complex, the need for reliable drainage solutions increases, making it imperative for manufacturers to keep pace.

Additionally, a 6% enhancement in efficiency can decrease operational costs. With reduced manufacturing time and minimal waste generation, companies can save on labor and material costs, translating to higher profit margins. This cost-effectiveness can also result in more competitive pricing for consumers, making half round gutters an attractive option for builders and homeowners alike.

Conclusion

In conclusion, the relevance of half round gutter machines in the construction and manufacturing industries cannot be overstated. As more builders seek aesthetically pleasing and functional water drainage solutions, the demand for these specialized machines will continue to rise. Manufacturers that focus on improving efficiency—including a targeted 6% increase—will not only benefit themselves but will also lead to more innovative and sustainable products in the market. As technology continues to evolve, the future of half round gutters looks promising, reinforcing their position as a staple in modern construction practices. By investing in high-quality machines and operational improvements, manufacturers can ensure they remain at the forefront of this vital industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025