Top Manufacturer of Roller Shutter Door Roll Forming Machines for Efficient Production Solutions

Roller Shutter Door Roll Forming Machine An Essential Tool for Manufacturers

In the modern construction and manufacturing landscape, roller shutter doors have become a staple for security and functionality. These versatile doors are commonly used in commercial and industrial settings, providing both protection and ease of access. At the heart of producing these doors lies a critical piece of equipment—the roller shutter door roll forming machine. This article delves into the significance of these machines, their operation, and the advantages they offer to manufacturers.

What is a Roller Shutter Door Roll Forming Machine?

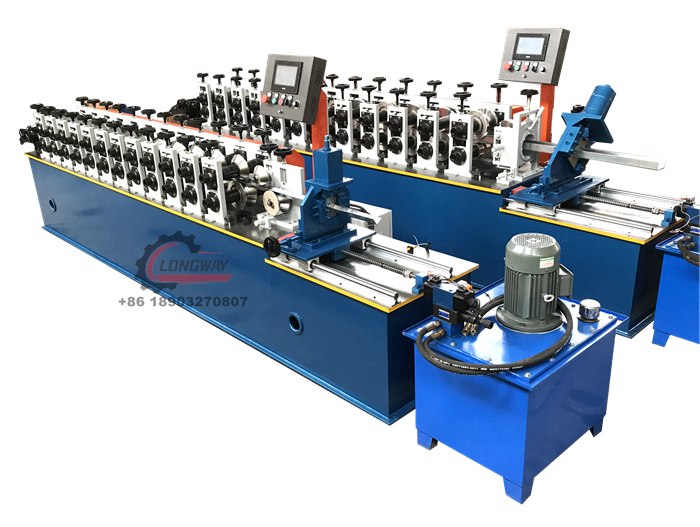

A roller shutter door roll forming machine is an industrial machine used to process metal sheets into roller shutter profiles. This machine takes a flat sheet of metal, typically galvanized steel or aluminum, and forms it into a series of interlocking slats that are then used to create a roller shutter door. The process involves several stages, including feeding, roll forming, cutting, and sometimes punching.

The Roll Forming Process

The operation of a roller shutter door roll forming machine begins with feeding the metal sheet into the machine. Rollers then shape the sheet through a series of carefully designed rollers that alter its profile. This forming process ensures that each slat has a consistent and precise shape, vital for the overall functionality of the door.

After the slats are formed, they typically go through a cutting stage where they are cut to the desired length. Some advanced roll forming machines are equipped with automatic cutting and feeding systems that enhance efficiency and reduce labor costs. Additionally, some machines may incorporate punching stations to create holes for locking mechanisms or other fittings directly during the roll forming process.

Advantages of Using a Roller Shutter Door Roll Forming Machine

roller shutter door roll forming machine manufacturer

1. Cost Efficiency The automation and efficiency of roll forming machines decrease labor costs and improve production rates. Manufacturers can produce large volumes of roller shutter doors in a shorter time compared to traditional methods.

2. Consistency and Precision The roll forming process allows for high precision in the dimensions of the slats, ensuring that each door fits perfectly during installation. This level of consistency is critical for maintaining quality control.

3. Versatility Many roll forming machines are customizable, capable of producing various profiles and sizes of roller shutter doors to meet different market demands. This flexibility enables manufacturers to cater to specific customer needs and preferences.

4. Durability and Strength Products made using a roll forming machine often exhibit superior quality due to the materials used and the inherent strength of the roll-formed profiles. Roller shutter doors created from high-grade steel or aluminum are robust and long-lasting, providing excellent security.

5. Space Efficient The compact design of modern roll forming machines allows them to be installed in facilities with limited space. Their efficient layout maximizes production without requiring vast operational areas.

Conclusion

The roller shutter door roll forming machine is an indispensable asset for manufacturers aiming to meet the growing demand for roller shutter doors. Its ability to produce high-quality, durable, and precise door profiles quickly and cost-effectively makes it a vital component in any metalworking operation. As industries continue to prioritize security and functional design in their architecture, the importance of efficient production methods—such as those offered by roll forming machines—will only increase. For manufacturers looking to enhance their capabilities, investing in a roller shutter door roll forming machine is a strategic move that offers long-term benefits and growth potential.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025