T-Grid Light Keel Roll Forming Equipment for Efficient Construction Solutions

The T-Grid Light Keel Roll Forming Machine Revolutionizing Construction

In recent years, the construction industry has witnessed a significant evolution in the methods employed for building frameworks. One of the standout innovations in this field is the T-grid light keel roll forming machine. This advanced piece of equipment has transformed how builders create ceilings and walls, making the construction process more efficient and cost-effective.

Understanding the T-Grid System

At the heart of contemporary ceiling systems is the T-grid structure, which is designed to support acoustic tiles, gypsum boards, and other lightweight materials. The T-grid consists of horizontal and vertical elements that create a grid pattern, enabling quick installation and easy maintenance. The light keel refers to the lightweight metal profiles used in this grid system, which are typically made from steel or aluminum. They are both strong and durable while remaining light enough for easy handling and installation.

The Role of the Roll Forming Machine

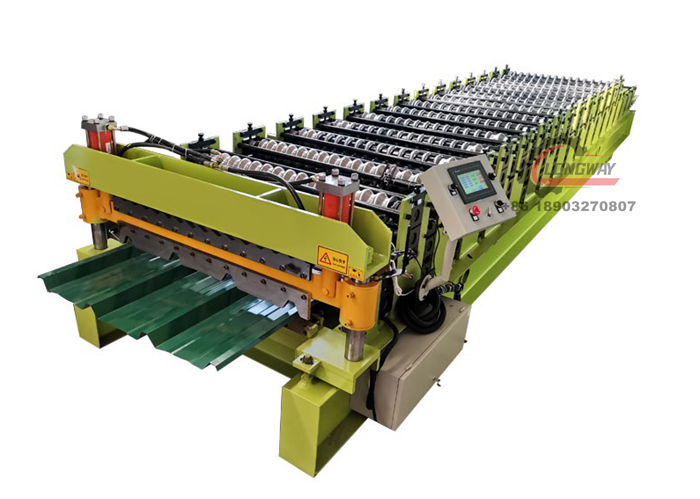

The T-grid light keel roll forming machine is engineered to automate the production of these metal profiles. Roll forming is a continuous bending operation where a long strip of sheet metal is passed through a series of rollers to obtain the desired cross-section. This process not only boosts production efficiency but also ensures uniformity and precision in the shapes produced.

Using a T-grid light keel roll forming machine dramatically reduces waste and labor costs compared to traditional manufacturing methods

. The operator controls the machine with ease, allowing for quick adjustments to meet different specifications based on project needs.Features and Benefits

t grid light keel roll forming machine

One of the most significant benefits of the T-grid light keel roll forming machine is its ability to produce various profiles in a single process. The machine can be customized to manufacture T-sections, U-sections, and other specialized shapes, accommodating diverse design requirements. This versatility means that construction companies can streamline their supply chains by obtaining multiple products from a single machine.

Additionally, the use of high-strength materials in the production of light keels enhances the structural integrity of the framework without adding unnecessary weight. This feature is particularly important in modern construction, where energy efficiency and sustainability are paramount. Lightweight structures can lead to reduced energy consumption, lower transportation costs, and minimized environmental impact.

Efficiency and Automation

The automation capabilities of the T-grid light keel roll forming machine further heighten its appeal in the construction sector. With features like automatic feeding systems, real-time monitoring, and computerized controls, operators can produce high-quality products with minimal manual intervention. This not only speeds up the production process but also reduces the likelihood of human error, ensuring consistent quality throughout the manufacturing run.

Conclusion

As the construction industry continues to evolve, the T-grid light keel roll forming machine stands out as a prime example of how technology can enhance traditional processes. By providing efficient, cost-effective, and high-quality solutions for ceiling and wall frameworks, this machine is poised to play a critical role in the future of construction.

Incorporating such advanced machinery into building projects allows for innovation in design and execution, ultimately leading to safer, smarter, and more sustainable structures. For builders looking to stay competitive in a rapidly changing market, investing in a T-grid light keel roll forming machine is not just an option; it’s an essential step toward modernization and efficiency.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025