Jul . 03, 2024 01:50

Back to list

Tailored Purlin Roll Forming Machinery for Efficient Steel Framing

The Customized Purlin Roll Forming Machine A Game-Changer in Modern Steel Construction

In the realm of steel construction, efficiency and precision are paramount. This is where the customized purlin roll forming machine steps into the limelight, revolutionizing the way structural components, particularly purlins, are manufactured. Purlins, crucial elements in roofing and wall systems, have traditionally been fabricated manually or with conventional machinery. However, the advent of the customized purlin roll forming machine has significantly streamlined this process.

A customized purlin roll forming machine is a high-tech, fully automated system designed to produce tailor-made purlins according to specific project requirements. It combines advanced engineering with digital technology to create a seamless production line that can handle various sizes, shapes, and materials with incredible accuracy and speed.

The heart of this machine lies in its flexibility and adaptability. Unlike standard roll formers, it can be programmed to produce an array of purlin profiles, from C-shaped to Z-shaped, and even complex designs, all with minimal setup time. This customization capability allows for greater design freedom and ensures a perfect fit for any architectural blueprint, whether for industrial sheds, warehouses, or commercial buildings.

The efficiency of the customized purlin roll forming machine is unparalleled. It can produce purlins at a rate that far surpasses manual methods, reducing labor costs and increasing productivity. Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site

Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site customized purlin roll forming machine. Moreover, the continuous operation of the machine allows for a consistent flow of materials, ensuring timely completion of projects.

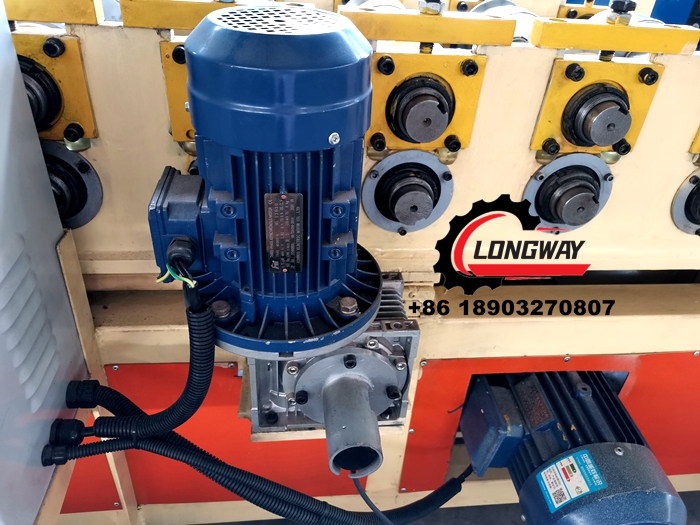

The robust construction of these machines guarantees durability and reliability, even under heavy workloads. They are equipped with high-quality components, including precision-formed rolls, powerful motors, and advanced control systems, ensuring smooth operation and longevity. Regular maintenance and updates can further enhance their performance and extend their service life.

Moreover, the customized purlin roll forming machine promotes sustainability in the construction industry. By optimizing material usage and reducing waste, it aligns with the growing demand for environmentally conscious practices. The machine's precision manufacturing also contributes to better structural integrity, leading to more energy-efficient buildings.

In conclusion, the customized purlin roll forming machine is not just a tool; it's a transformative solution in steel construction. It brings together innovation, precision, and efficiency to streamline the purlin production process, enabling builders to meet diverse project demands with ease. As technology continues to advance, we can expect these machines to become even more sophisticated, pushing the boundaries of what's possible in steel fabrication and propelling the construction industry towards a more efficient and sustainable future.

customized purlin roll forming machine. Moreover, the continuous operation of the machine allows for a consistent flow of materials, ensuring timely completion of projects.

The robust construction of these machines guarantees durability and reliability, even under heavy workloads. They are equipped with high-quality components, including precision-formed rolls, powerful motors, and advanced control systems, ensuring smooth operation and longevity. Regular maintenance and updates can further enhance their performance and extend their service life.

Moreover, the customized purlin roll forming machine promotes sustainability in the construction industry. By optimizing material usage and reducing waste, it aligns with the growing demand for environmentally conscious practices. The machine's precision manufacturing also contributes to better structural integrity, leading to more energy-efficient buildings.

In conclusion, the customized purlin roll forming machine is not just a tool; it's a transformative solution in steel construction. It brings together innovation, precision, and efficiency to streamline the purlin production process, enabling builders to meet diverse project demands with ease. As technology continues to advance, we can expect these machines to become even more sophisticated, pushing the boundaries of what's possible in steel fabrication and propelling the construction industry towards a more efficient and sustainable future.

Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site

Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site Its precision engineering ensures that each purlin is manufactured to exact specifications, minimizing waste and errors on site customized purlin roll forming machine. Moreover, the continuous operation of the machine allows for a consistent flow of materials, ensuring timely completion of projects.

The robust construction of these machines guarantees durability and reliability, even under heavy workloads. They are equipped with high-quality components, including precision-formed rolls, powerful motors, and advanced control systems, ensuring smooth operation and longevity. Regular maintenance and updates can further enhance their performance and extend their service life.

Moreover, the customized purlin roll forming machine promotes sustainability in the construction industry. By optimizing material usage and reducing waste, it aligns with the growing demand for environmentally conscious practices. The machine's precision manufacturing also contributes to better structural integrity, leading to more energy-efficient buildings.

In conclusion, the customized purlin roll forming machine is not just a tool; it's a transformative solution in steel construction. It brings together innovation, precision, and efficiency to streamline the purlin production process, enabling builders to meet diverse project demands with ease. As technology continues to advance, we can expect these machines to become even more sophisticated, pushing the boundaries of what's possible in steel fabrication and propelling the construction industry towards a more efficient and sustainable future.

customized purlin roll forming machine. Moreover, the continuous operation of the machine allows for a consistent flow of materials, ensuring timely completion of projects.

The robust construction of these machines guarantees durability and reliability, even under heavy workloads. They are equipped with high-quality components, including precision-formed rolls, powerful motors, and advanced control systems, ensuring smooth operation and longevity. Regular maintenance and updates can further enhance their performance and extend their service life.

Moreover, the customized purlin roll forming machine promotes sustainability in the construction industry. By optimizing material usage and reducing waste, it aligns with the growing demand for environmentally conscious practices. The machine's precision manufacturing also contributes to better structural integrity, leading to more energy-efficient buildings.

In conclusion, the customized purlin roll forming machine is not just a tool; it's a transformative solution in steel construction. It brings together innovation, precision, and efficiency to streamline the purlin production process, enabling builders to meet diverse project demands with ease. As technology continues to advance, we can expect these machines to become even more sophisticated, pushing the boundaries of what's possible in steel fabrication and propelling the construction industry towards a more efficient and sustainable future. Latest news

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025

Related Products