Top Manufacturers of Stud Roll Forming Machines in the Industry Today

Exploring the World of Stud Roll Forming Machine Manufacturers

In the realm of modern manufacturing, efficiency and precision are paramount. One of the key technologies contributing to these ideals in the construction and building sector is the stud roll forming machine. This innovative piece of machinery is essential for producing metal studs and tracks that are widely used in framing, partitioning, and various other applications. As demand for sophisticated building materials increases, the significance of stud roll forming machine manufacturers has surged, leading to a competitive market characterized by technological advancements and diverse offerings.

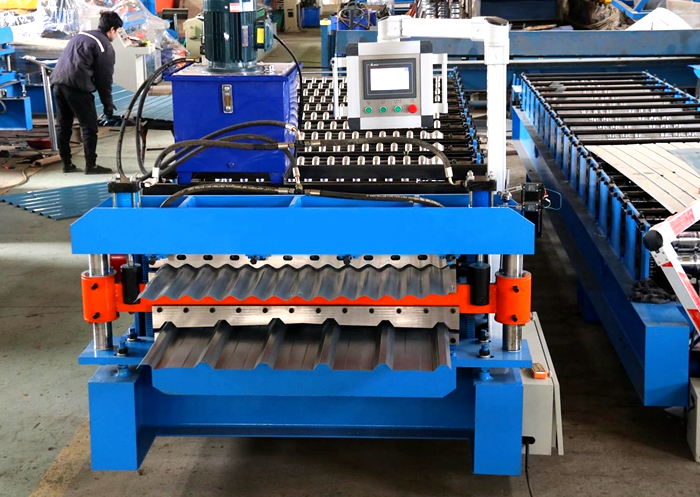

Stud roll forming machines operate by continuously shaping metal strips into specific profiles, which are then used to create sturdy and lightweight structures. These machines can produce a variety of shapes and sizes, allowing builders and contractors to customize their projects according to specific requirements. The process of roll forming is not only efficient but also reduces material waste, making it an environmentally friendly option compared to traditional methods of metal fabrication.

When it comes to choosing a stud roll forming machine manufacturer, there are several factors to consider. Quality and reliability are crucial, as the performance of the machine directly influences the overall productivity of a manufacturing operation. Reputable manufacturers typically use high-grade materials in their machines, ensuring durability and longevity. Moreover, the design of the machine, including its roll tooling and the precision of its components, plays a vital role in achieving consistent results.

Another important factor is the technological innovation that manufacturers bring to the table. Many leading companies are now integrating advanced technology into their machines. For instance, some machines come with computerized controls that allow for real-time adjustments and monitoring, ensuring high precision and efficiency. Automation features also help reduce manual labor, enabling manufacturers to produce higher volumes with less effort.

stud roll forming machine manufacturers

The global market for stud roll forming machines has witnessed significant growth, driven by increasing investments in construction and infrastructure. Manufacturers are stepping up to meet this demand by offering a wide range of products tailored to various industry needs. From compact machines suitable for small workshops to large industrial units capable of high-volume production, the options are vast and diverse.

In addition to performance and features, customer support and service are critical aspects to consider when selecting a manufacturer. A reputable company will offer comprehensive after-sales service, including installation, training, and maintenance support. This ensures that clients can maximize the productivity of their machines while minimizing downtime.

Furthermore, as sustainability becomes an essential consideration in the manufacturing process, many stud roll forming machine manufacturers are working to enhance the energy efficiency of their products. Eco-friendly practices, such as minimizing energy consumption during operation and employing recyclable materials, are increasingly becoming standard in the industry.

In conclusion, the role of stud roll forming machine manufacturers in the construction and manufacturing sectors is more significant than ever. With advancements in technology and a commitment to quality and customer service, these manufacturers are not only meeting the growing demand for metal framing solutions but also shaping the future of sustainable construction practices. As projects continue to evolve and the industry advances, the innovations and offerings from stud roll forming machine manufacturers will undoubtedly play a crucial role in addressing the challenges and opportunities that lie ahead.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025