Roll Forming Machine Manufacturer for High-Quality Steel Products and Custom Solutions

Understanding the Role of Stud Roll Forming Machines in Modern Manufacturing

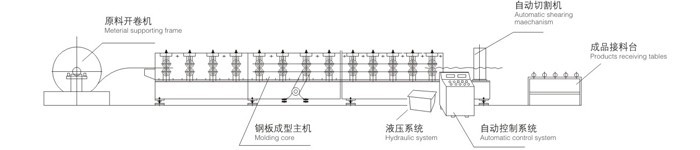

In the ever-evolving landscape of manufacturing, efficiency, precision, and adaptability are paramount. Among the myriad of machines employed in the production process, the stud roll forming machine stands out as a vital tool, particularly in the construction and framing industries. These machines offer an efficient solution for producing metal studs, tracks, and various structural components essential for building projects.

Understanding the Role of Stud Roll Forming Machines in Modern Manufacturing

One of the primary benefits of utilizing a stud roll forming machine is its ability to create complex shapes with precision. As building designs evolve, architects and engineers are increasingly pushing the boundaries of structural aesthetics and functionality. Roll forming enables the production of intricate profiles that can accommodate various architectural styles while maintaining the necessary structural integrity. This capability is especially crucial in today’s highly competitive market, where unique and customized designs are often in demand.

stud roll forming machine factory

Additionally, the efficiency of stud roll forming machines significantly reduces labor costs. Traditional methods of metal fabrication often require extensive manual labor and time-consuming processes. In contrast, roll forming machines can produce thousands of feet of product in a fraction of the time, allowing companies to meet tight deadlines without compromising quality. This automation not only increases productivity but also minimizes human error, ensuring a more reliable outcome.

Durability is another key advantage of products manufactured using stud roll forming machines. The materials used are typically treated to withstand corrosion and other environmental factors, resulting in long-lasting structural components. This durability is a crucial factor in construction, where safety and longevity are paramount. Builders and contractors can trust that the metal studs and tracks created through this process will maintain their integrity throughout the life of the building, thereby enhancing overall safety and reducing the need for future repairs.

Moreover, the adaptability of stud roll forming machines allows manufacturers to pivot quickly in response to market demands. With the ability to adjust the design parameters and tooling, these machines can produce various profiles without significant downtime or production halts. This flexibility enables companies to diversify their product offerings, catering to a broad range of customer needs, from residential projects to large-scale commercial constructions.

In conclusion, the stud roll forming machine represents a transformative technology in modern manufacturing, particularly within the construction sector. Its combination of efficiency, precision, and adaptability makes it an invaluable asset for companies striving to maintain a competitive edge. As the demand for innovative building solutions continues to rise, the role of stud roll forming machines will undoubtedly grow, driving advancements in construction technology and contributing to the creation of safer, more resilient structures. Embracing this technology is not just an option but a necessity for manufacturers aiming to thrive in today’s fast-paced industrial environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025