stud roll forming machine

Understanding Stud Roll Forming Machines

In the world of metal fabrication, the demand for precision and efficiency has led to the emergence of various advanced manufacturing technologies. Among these, stud roll forming machines stand out as a vital piece of equipment in producing metal studs and tracks used in construction and various industrial applications. This article aims to provide an in-depth look at the process, advantages, and applications of stud roll forming machines.

What is a Stud Roll Forming Machine?

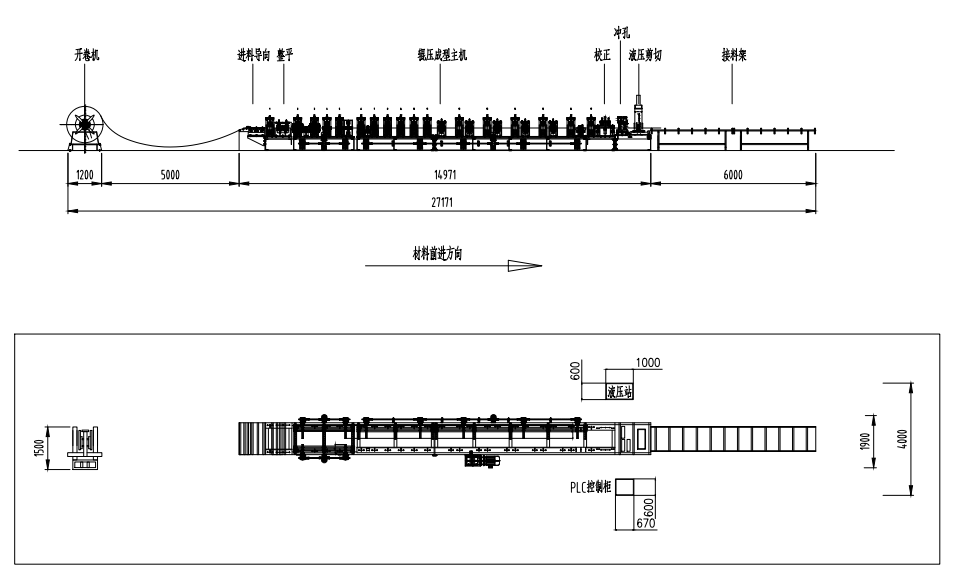

A stud roll forming machine is a specialized piece of machinery designed to create metal studs and tracks from raw metal sheets or coils. The process involves feeding a flat metal strip through a series of rollers that progressively shape the material into a desired profile. The end result is a series of uniform metal studs, which are integral components in the construction of walls, ceilings, and other structures.

The Roll Forming Process

The roll forming process is a continuous bending operation where a long strip of metal is passed through multiple stations. Each station is equipped with rollers that gradually shape the metal into the specific profile required for the application. The machines are designed to operate efficiently, creating high volumes of product within a short time while maintaining consistent quality.

1. Material Feed The process begins with a coil of metal, typically made of galvanized steel or other durable materials, which is unwound and fed into the machine.

2. Forming Stations As the metal strip passes through a series of forming stations, each equipped with specially designed rollers, it is shaped into a profile that often resembles a C or U shape. Each roller imparts a percentage of the final shape, with multiple stations working together for precision.

3. Cutting and Finishing Once formed, the metal is cut to length, and additional features such as holes or notches can be added, depending on the specifications needed for the final product.

Advantages of Stud Roll Forming Machines

Stud roll forming machines offer a plethora of benefits that make them an attractive choice for metal fabrication

- High Efficiency These machines can produce a large number of studs in a relatively short period, which is crucial for meeting the demands of large construction projects.

stud roll forming machine

- Consistency The automated nature of the process ensures that every stud produced is nearly identical, which is essential for structural integrity and ease of installation

.- Cost-Effectiveness With the ability to produce large volumes quickly, companies can reduce labor and material costs. Additionally, the scrap rate is low due to the continuous feeding process.

- Versatility Stud roll forming machines can be designed to produce various stud sizes and shapes, making them suitable for diverse applications beyond construction, including automotive and furniture manufacturing.

Applications of Stud Roll Forming Machines

The applications of stud roll forming machines are extensive, primarily focused on the construction industry

- Drywall and Metal Framing Metal studs are commonly used in drywall construction, providing a sturdy framework for walls and ceilings.

- Industrial and Commercial Buildings These machines support the construction of large-scale structures where metal studs are essential for supporting load-bearing walls.

- Furniture Manufacturing The versatility of the machines allows them to be used in producing components for metal furniture, cabinetry, and fixtures.

- Automotive and Aerospace Stud roll forming machines are also utilized in the production of lightweight components that require high strength-to-weight ratios.

Conclusion

Stud roll forming machines play an essential role in modern manufacturing, particularly in the construction industry. With their ability to produce high volumes of precise metal studs quickly and efficiently, they contribute to the rapid growth and development of infrastructure. As technology continues to advance, these machines will likely become even more sophisticated, offering enhanced precision and customization capabilities, further solidifying their place in the world of metal fabrication. With their myriad applications and benefits, stud roll forming machines are not just tools; they are vital enablers of innovation in construction and manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025