Jan . 09, 2025 13:48

Back to list

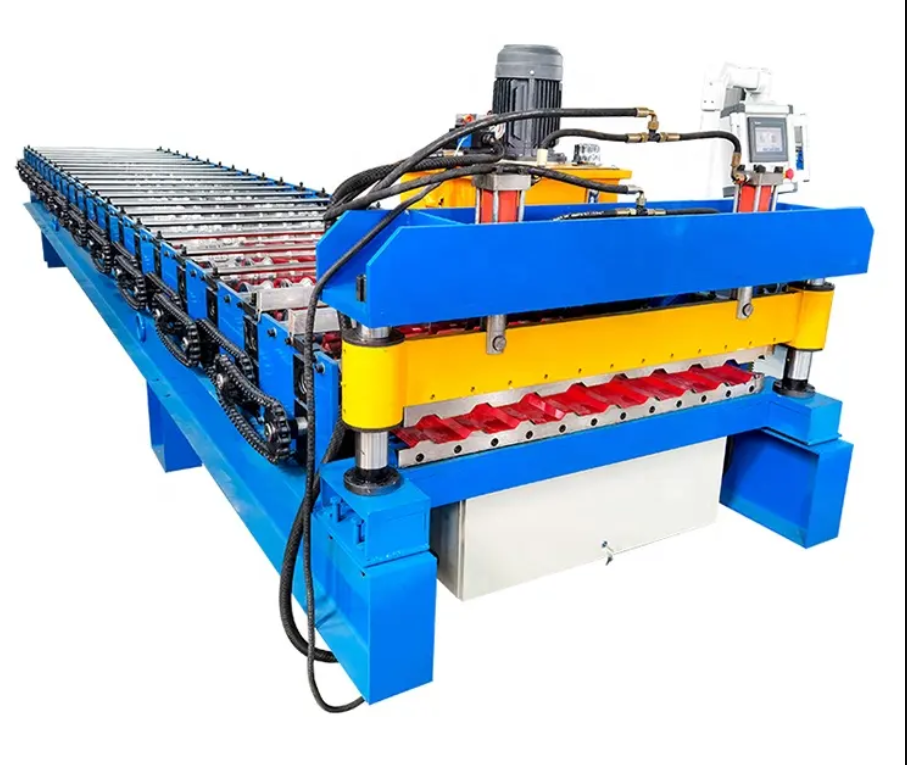

320 Cladding wall panel roll former

In the dynamic landscape of modern manufacturing, the stud and track roll forming machine stands out as an indispensable tool for producing consistent and high-quality metal components. Leveraging cutting-edge technology, this machine has revolutionized the way industries approach construction and fabrication, embedding efficiency and precision into every aspect of the process.

The authority of a stud and track roll forming machine is further realized through its adaptability across various sectors. Whether it's in construction, where metal studs and tracks form the backbone of drywall installations, or in automotive industries where precision metal shaping is critical, this machine's versatility makes it a cornerstone of industrial productivity. The ability to customize profiles according to project demands renders it invaluable, offering manufacturers a competitive edge in bespoke production solutions. Trust in a stud and track roll forming machine is solidified through rigorous quality assurance protocols. Manufacturers subject these machines to stringent testing phases to ensure reliability and durability under various operational conditions. Moreover, the integration of smart technologies, such as real-time monitoring and automated adjustment features, bolsters operational transparency and fault detection, further reinforcing user confidence. For those seeking to invest in a stud and track roll forming machine, it's crucial to consider factors such as the machine's capacity, compatibility with existing production lines, and the support infrastructure provided by the manufacturer. Engaging with a reputable supplier not only guarantees a high-quality product but also ensures access to after-sale services such as regular maintenance, parts replacement, and technical support—vital elements that maintain the longevity and efficiency of industrial machinery. In essence, the stud and track roll forming machine symbolizes a convergence of engineering prowess and practical application, embodying the future of efficient manufacturing. Its innovative design principles and operational reliability make it a powerful asset, promising both economic and qualitative benefits to users poised to harness its full potential in the ever-evolving world of industrial production.

The authority of a stud and track roll forming machine is further realized through its adaptability across various sectors. Whether it's in construction, where metal studs and tracks form the backbone of drywall installations, or in automotive industries where precision metal shaping is critical, this machine's versatility makes it a cornerstone of industrial productivity. The ability to customize profiles according to project demands renders it invaluable, offering manufacturers a competitive edge in bespoke production solutions. Trust in a stud and track roll forming machine is solidified through rigorous quality assurance protocols. Manufacturers subject these machines to stringent testing phases to ensure reliability and durability under various operational conditions. Moreover, the integration of smart technologies, such as real-time monitoring and automated adjustment features, bolsters operational transparency and fault detection, further reinforcing user confidence. For those seeking to invest in a stud and track roll forming machine, it's crucial to consider factors such as the machine's capacity, compatibility with existing production lines, and the support infrastructure provided by the manufacturer. Engaging with a reputable supplier not only guarantees a high-quality product but also ensures access to after-sale services such as regular maintenance, parts replacement, and technical support—vital elements that maintain the longevity and efficiency of industrial machinery. In essence, the stud and track roll forming machine symbolizes a convergence of engineering prowess and practical application, embodying the future of efficient manufacturing. Its innovative design principles and operational reliability make it a powerful asset, promising both economic and qualitative benefits to users poised to harness its full potential in the ever-evolving world of industrial production.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products