Jan . 09, 2025 11:26

Back to list

stud and track roll forming machine

Stud and track roll forming machines have revolutionized the construction and manufacturing industries, offering unparalleled precision and efficiency. These machines are critical for producing metal framing components, essential in modern building projects due to their durability and cost-effectiveness. As industries strive for more sustainable and efficient construction methods, understanding the nuances of these machines becomes vital.

For businesses looking to invest in stud and track roll forming machines, certain factors should be considered. It is crucial to assess the machine's compatibility with various metal types and thicknesses, as flexibility in handling different materials can expand your production capabilities. Evaluating the machine's speed, maintenance requirements, and ease of operation will also ensure that it aligns well with your production needs and workforce capacity. Ensuring that the machine comes with reliable after-sales support and warranties is essential to maintain uninterrupted operations. Expertise in operating these machines plays a significant role in maximizing their potential. Investing in skilled operators or comprehensive training programs can enhance production quality and efficiency. Furthermore, working with suppliers who have a strong track record and industry reputation can provide access to the latest technological advancements and best practices, enhancing your competitive edge. In conclusion, the stud and track roll forming machine stands as a remarkable innovation that combines efficiency, precision, and adaptability. For businesses in the construction and manufacturing industries, understanding and leveraging the capabilities of these machines can drive significant productivity and cost benefits, making them an invaluable asset in modern production environments.

For businesses looking to invest in stud and track roll forming machines, certain factors should be considered. It is crucial to assess the machine's compatibility with various metal types and thicknesses, as flexibility in handling different materials can expand your production capabilities. Evaluating the machine's speed, maintenance requirements, and ease of operation will also ensure that it aligns well with your production needs and workforce capacity. Ensuring that the machine comes with reliable after-sales support and warranties is essential to maintain uninterrupted operations. Expertise in operating these machines plays a significant role in maximizing their potential. Investing in skilled operators or comprehensive training programs can enhance production quality and efficiency. Furthermore, working with suppliers who have a strong track record and industry reputation can provide access to the latest technological advancements and best practices, enhancing your competitive edge. In conclusion, the stud and track roll forming machine stands as a remarkable innovation that combines efficiency, precision, and adaptability. For businesses in the construction and manufacturing industries, understanding and leveraging the capabilities of these machines can drive significant productivity and cost benefits, making them an invaluable asset in modern production environments.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

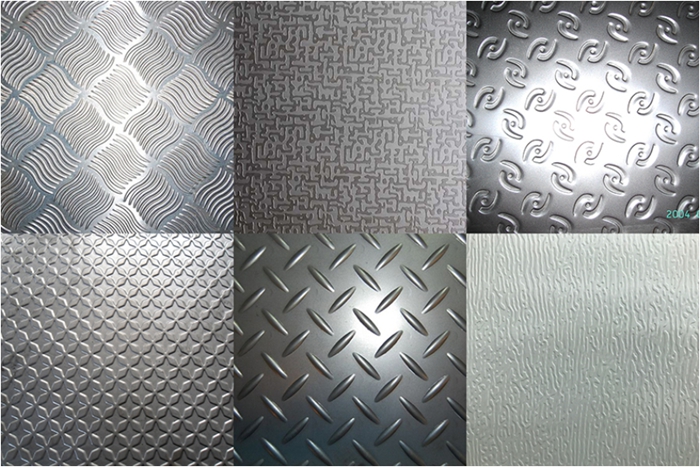

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products