Monitoring and Analyzing Performance in Manufacturing Machinery Factories for Improved Efficiency

Stud and Track Machine Factories A Closer Look at Their Role in Modern Manufacturing

In today's fast-paced industrial landscape, the demand for precision and efficiency has never been higher. One crucial component in achieving these objectives is the equipment used in manufacturing processes, especially in the fabrication of stud and track systems. Stud and track machines are essential tools for the construction and building industries, providing the necessary components for framing and structural support. This article delves into the significance of stud and track machine factories, their processes, and their impact on modern manufacturing.

Understanding Stud and Track Machines

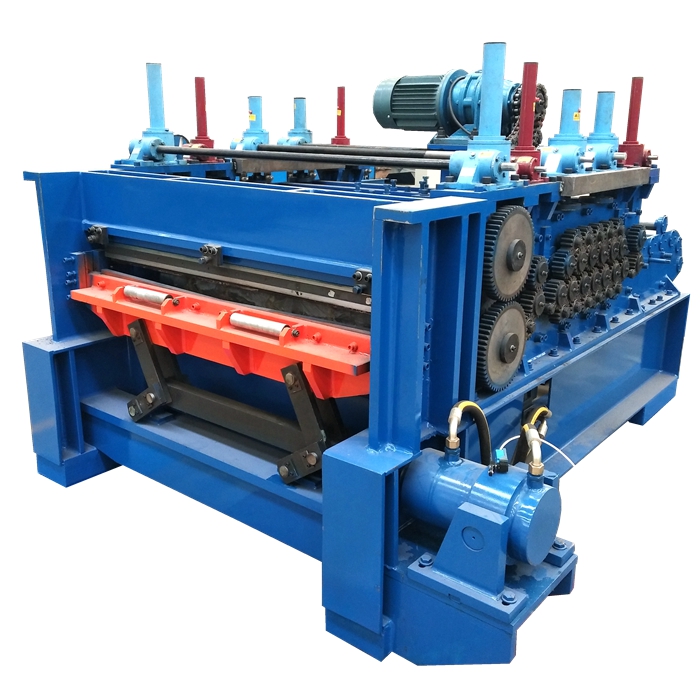

Stud and track machines are specialized equipment designed to produce metal framing components, predominantly used in drywall construction. These machines enable manufacturers to create studs—vertical framing members—and tracks—horizontal components that hold the studs in place—efficiently and accurately. The production process involves feeding metal coils into the machine, which then cuts, bends, and forms the metal into the desired shapes and dimensions. The result is a consistent and reliable product that meets industry standards.

The Role of Factories in Production

Stud and track machine factories play a pivotal role in the production chain. These factories are equipped with advanced machinery and technology to ensure that the production process is streamlined. Automation has taken center stage in these facilities, where computer numerical control (CNC) machines optimize the cutting and shaping processes, significantly increasing production rates while minimizing human error.

Furthermore, the factories are designed to maintain high standards of quality control. Rigorous testing and inspection protocols are implemented to guarantee that the finished products meet the required specifications. This attention to detail is crucial, as the integrity of the stud and track systems directly impacts the safety and durability of structures.

stud and track machine factories

Eco-friendly Manufacturing Practices

In recent years, there has been a growing emphasis on sustainability within manufacturing processes. Stud and track machine factories are no exception, with many adopting eco-friendly practices. This includes optimizing material usage to reduce waste and implementing recycling programs for scrap metal. Additionally, sustainable energy sources, such as solar and wind power, are being integrated into production facilities to decrease their carbon footprint.

Market Demand and Innovation

The construction industry is constantly evolving, and so are the demands for stud and track systems. As modular construction and prefabrication become more popular, there is an increasing need for innovative solutions. Factories are responding by investing in research and development to create machines that offer greater versatility, allowing for the production of various framing components in a single setup.

Furthermore, advancements in technology have enabled factories to incorporate smart manufacturing techniques. Internet of Things (IoT) devices are being used to monitor equipment performance and predict maintenance needs, which can prevent costly downtimes and enhance overall productivity.

Conclusion

Stud and track machine factories are vital to the construction and manufacturing sectors, providing the foundation for modern building practices. Their contribution extends beyond simple production; they embody innovation, efficiency, and sustainability. As the industry continues to evolve, these factories will play an even more significant role in shaping the future of construction, ensuring that structures are built to withstand the test of time while meeting the increasing demands of contemporary society. In this ever-changing landscape, embracing technology and sustainable practices will be key to remaining competitive and relevant in the marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025