Leading Supplier of Step Tiles Roll Forming Machines for Quality Production

Understanding Step Tiles Roll Forming Machines and Their Suppliers

In the evolving landscape of manufacturing, particularly in the building materials sector, one machine stands out for its efficiency and versatility the step tiles roll forming machine. As the demand for high-quality, durable roofing solutions increases, manufacturers and construction companies are turning to these specialized machines for effective production. This article explores the significance of step tiles roll forming machines and outlines the key features to consider when selecting a reliable supplier.

What is a Step Tiles Roll Forming Machine?

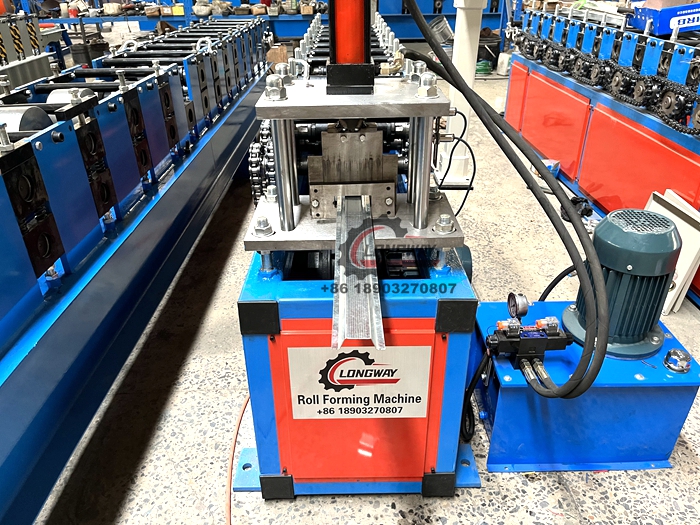

A step tiles roll forming machine is a type of industrial equipment designed to convert metal coils into step tiles used primarily in roofing applications. These machines operate by continuously feeding metal sheets or coils into a series of rollers that gradually shape the material into the desired tile profile. The end result is a series of step tiles that offer both aesthetic appeal and functional benefits, including improved weather resistance and structural strength.

Features and Benefits of Step Tiles

Step tiles are popular due to their unique design and performance characteristics. They are engineered to mimic traditional roofing materials, such as clay tiles, but provide added advantages. Key features of step tiles include

1. Durability Made from high-quality metals like steel or aluminum, step tiles are resistant to harsh weather conditions, ensuring long-lasting performance. 2. Ease of Installation The uniform size and shape of step tiles simplify the installation process, allowing for quicker assembly and reducing labor costs.

3. Aesthetic Appeal Available in various finishes and colors, step tiles can enhance the curb appeal of any building, from residential homes to commercial properties.

Selecting the Right Supplier

step tiles roll forming machine supplier

When embarking on the journey to acquire a step tiles roll forming machine, choosing the right supplier is paramount. Here are some essential factors to consider

1. Experience and Expertise Look for suppliers with a proven track record in manufacturing roll forming machines. An experienced supplier will have the knowledge to guide you in selecting the best machine for your specific needs.

2. Quality Assurance Ensure that the supplier adheres to stringent quality control measures. This includes using high-quality materials and implementing robust manufacturing processes to produce reliable and durable machines.

3. Customization Options Different projects may require unique specifications. A good supplier should offer customization options to tailor the machine to your requirements, including specific tile profiles and production capacities.

4. After-Sales Support Consider the level of after-sales support offered by the supplier. A reputable supplier will provide installation guidance, training for operators, and ongoing maintenance services to ensure optimal machine performance.

5. Customer Feedback Research customer reviews and testimonials. Feedback from previous clients can provide valuable insights into the supplier’s reliability, product quality, and customer service.

6. Technological Advancements As manufacturing technology evolves, it’s essential to choose a supplier that invests in innovation. Look for suppliers that incorporate the latest technology in their machines, such as automation and energy efficiency, to enhance productivity and reduce operational costs.

Conclusion

In conclusion, the step tiles roll forming machine plays a crucial role in today's construction industry, facilitating the production of high-quality roofing materials that cater to various aesthetic and functional demands. By understanding the importance of these machines and carefully selecting a reputable supplier, manufacturers can ensure they meet market demands while maintaining high standards of quality and efficiency. The right partnership with a reliable machine supplier can lead to increased productivity, cost savings, and ultimately, greater customer satisfaction in the competitive world of construction and manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025