Feb . 01, 2025 03:59

Back to list

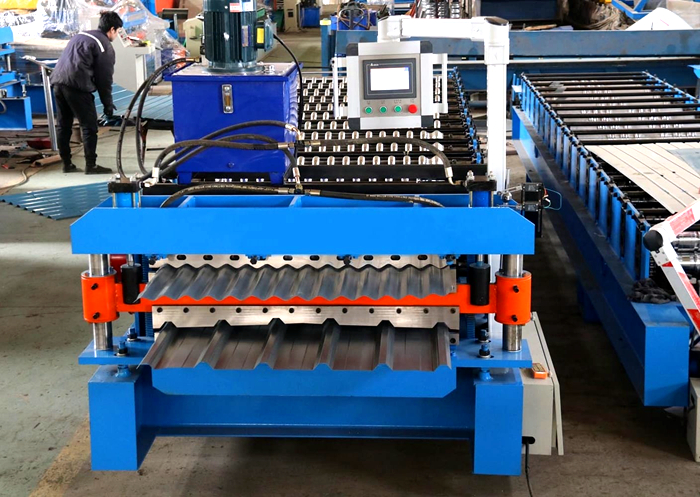

cladding roll forming machine

In the world of industrial machinery, the step tile roll forming machine is an unparalleled innovation, bringing both technological advancement and precision to the roofing industry. This sophisticated equipment is designed to transform metal coils into step tiles used in residential and commercial buildings. The demand for these machines has escalated due to their efficiency, cost-effectiveness, and the high quality of the end products they produce.

The step tile roll forming machine is also critically acclaimed for its sustainability. By minimizing material waste and optimizing energy consumption, these machines contribute to greener manufacturing processes. This sustainability aspect not only helps in reducing operational costs but also aligns with global eco-friendly practices, making it an ideal choice for businesses committed to reducing their carbon footprint. Investing in a step tile roll forming machine is not just about keeping up with current manufacturing trends, but also about preparing for future challenges. As building regulations and consumer preferences evolve, having a machine that accommodates flexibility in design and material choice will be invaluable. Moreover, manufacturers can stay ahead of competitors by producing innovative roofing solutions that meet emerging aesthetic and functional demands. The maintenance of these machines is another area where expertise transforms operational efficiency. Routine maintenance ensures a longer machine lifespan and consistent product quality, all while avoiding unexpected downtimes. A knowledgeable operator or technician can easily oversee the preventive maintenance tasks required, maintaining optimal machine function and safeguarding the investment. When choosing a step tile roll forming machine, it is essential to consider the supplier's reputation, technical support, and after-sale service. Engaging with a reputable supplier guarantees not only the quality of the machine but also access to ongoing support and service that can resolve any operational issues swiftly. In conclusion, a step tile roll forming machine is a cornerstone of modern roofing tile production. Its blend of speed, precision, versatility, and sustainability makes it indispensable in the field. Companies in the roofing industry reap substantial benefits, from reduced production costs to expanded product offerings, by integrating these machines into their operations. As a result, these machines not only align manufacturers with current market trends but also position them to address future demands efficiently and sustainably.

The step tile roll forming machine is also critically acclaimed for its sustainability. By minimizing material waste and optimizing energy consumption, these machines contribute to greener manufacturing processes. This sustainability aspect not only helps in reducing operational costs but also aligns with global eco-friendly practices, making it an ideal choice for businesses committed to reducing their carbon footprint. Investing in a step tile roll forming machine is not just about keeping up with current manufacturing trends, but also about preparing for future challenges. As building regulations and consumer preferences evolve, having a machine that accommodates flexibility in design and material choice will be invaluable. Moreover, manufacturers can stay ahead of competitors by producing innovative roofing solutions that meet emerging aesthetic and functional demands. The maintenance of these machines is another area where expertise transforms operational efficiency. Routine maintenance ensures a longer machine lifespan and consistent product quality, all while avoiding unexpected downtimes. A knowledgeable operator or technician can easily oversee the preventive maintenance tasks required, maintaining optimal machine function and safeguarding the investment. When choosing a step tile roll forming machine, it is essential to consider the supplier's reputation, technical support, and after-sale service. Engaging with a reputable supplier guarantees not only the quality of the machine but also access to ongoing support and service that can resolve any operational issues swiftly. In conclusion, a step tile roll forming machine is a cornerstone of modern roofing tile production. Its blend of speed, precision, versatility, and sustainability makes it indispensable in the field. Companies in the roofing industry reap substantial benefits, from reduced production costs to expanded product offerings, by integrating these machines into their operations. As a result, these machines not only align manufacturers with current market trends but also position them to address future demands efficiently and sustainably.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products