Steel Slitting Line Manufacturing Solutions for Precision Metal Processing Requirements

The Evolution of Steel Slitting Line Factories

In the modern manufacturing landscape, steel slitting line factories play a pivotal role in the processing of steel coils into precise strips of various widths. As industries advance and the demand for customized steel products increases, the evolution of these factories becomes a critical topic for discussion.

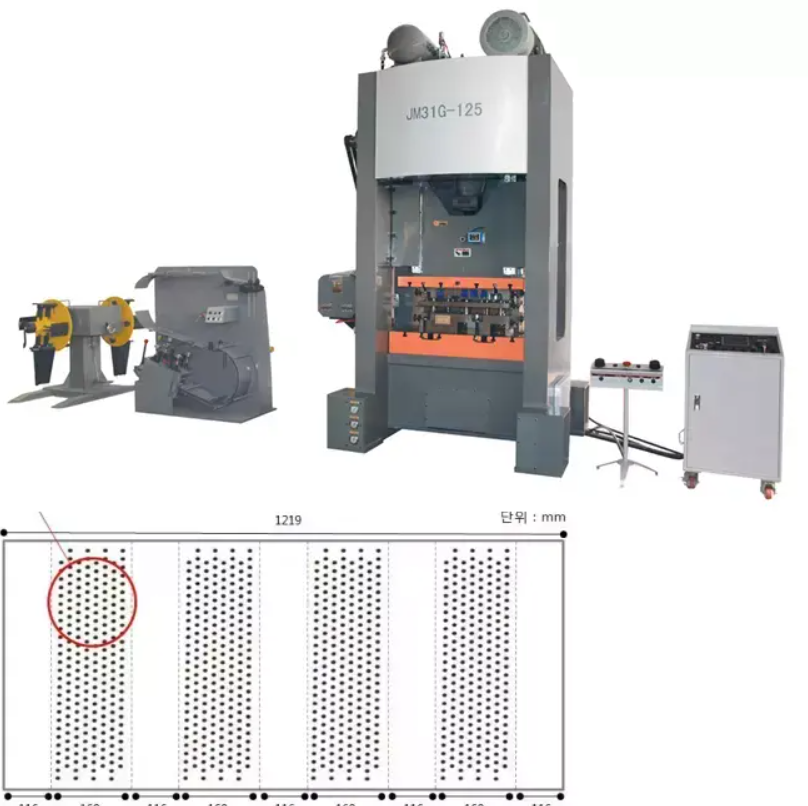

Understanding Steel Slitting Lines

A steel slitting line is a specialized machine used to cut wide steel coils into narrower strips. The slitting process involves several steps, including uncoiling, slitting, recoiling, and packaging. The slitting line typically includes essential components such as a decoiler, slitting machine, tension leveler, recoiler, and a scrap removal system. The precision of this process is crucial, as it directly affects the quality and usability of the final product.

Importance in Modern Manufacturing

Steel slitting lines are indispensable in various industries, including automotive, construction, and appliance manufacturing. Companies require specific widths and gauges of steel to meet their production needs, and slitting lines provide the solution. The ability to efficiently and effectively produce narrow strips of steel has allowed manufacturers to optimize their supply chains, reduce waste, and improve their overall production processes.

Technological Advancements

The steel processing industry has witnessed remarkable technological advancements over recent years. Innovations in automation and controls have significantly improved the performance of slitting lines. Modern slitting lines can operate at high speeds, often exceeding 1,000 feet per minute, and incorporate advanced software for better inventory management and tracking.

Additionally, the introduction of servo technology allows for improved precision and reduced setup times. These technologies contribute to the production of higher-quality products while minimizing labor costs. Manufacturers are increasingly opting for hybrid systems that combine traditional methods with modern technology, leading to greater efficiency and adaptability in production processes.

steel slitting line factory

Environmental Considerations

In today’s industrial environment, sustainability is a primary concern. Steel slitting line factories are adapting to this need by implementing environmentally friendly practices. Waste reduction is at the forefront, with advanced scrap handling systems that ensure maximum recovery and reusability of materials. Moreover, numerous factories are investing in energy-efficient machinery and processes to reduce their carbon footprint.

Some factories have also begun to utilize renewable energy sources, such as solar or wind power, to sustain their operations. By transitioning to more sustainable practices, steel slitting line factories are not only complying with regulatory standards but also appealing to environmentally conscious consumers.

The Future of Steel Slitting Line Factories

Looking ahead, the future of steel slitting line factories appears promising. As global demand for steel continues to rise, these factories will need to adapt to provide not only a wide range of steel products but also enhanced services. Customization and flexibility will become the norm as industries increasingly seek tailored solutions for their specific requirements.

Furthermore, the integration of Industry 4.0 practices is on the horizon. This includes the use of the Internet of Things (IoT), big data analytics, and artificial intelligence (AI) to create smart factories that can monitor and optimize processes in real time. By leveraging these technologies, steel slitting line factories will be able to enhance productivity and reduce downtime, driving efficiencies in the manufacturing process.

Conclusion

Steel slitting line factories are an integral part of the steel manufacturing ecosystem. Their importance in supplying precision steel strips cannot be overstated, as they enable a wide array of industries to innovate and thrive. With continual advancements in technology and a focus on sustainability, these factories stand to evolve significantly in the coming years.

As the steel industry adapts to changing market demands and environmental pressures, steel slitting line factories will remain at the forefront, ensuring that manufacturers have the high-quality materials they need to succeed. The commitment to modernization, efficiency, and sustainability will drive the industry forward, setting the stage for a new era in steel processing. In this ever-evolving landscape, the steel slitting line factory will undoubtedly continue to be a cornerstone of industrial manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025