Steel Sheet Rolling Equipment for Efficient Sheet Metal Fabrication Processes

Understanding Steel Sheet Roll Forming Machines

Steel sheet roll forming machines play a pivotal role in the manufacturing industry, particularly in producing metal profiles used in various applications. These machines utilize a process where flat steel sheets are fed through a series of rollers to create continuous lengths of shaped sections. This technology has revolutionized the way metal components are produced, offering efficiency, precision, and versatility.

The Basics of Roll Forming

The roll forming process begins with a flat metal sheet, typically made of steel, aluminum, or other alloys. The sheet is unwound from a coil and passed through a series of rollers that gradually shape it into the desired profile. Each roller in the sequence contributes to the incremental change in shape until the final product is achieved. The process is highly automated, allowing manufacturers to produce large quantities of uniformly shaped components with minimal labor.

Key Components of a Steel Sheet Roll Forming Machine

1. Decoiler This feeding system unwinds the steel coil and ensures that it feeds smoothly into the roll forming process.

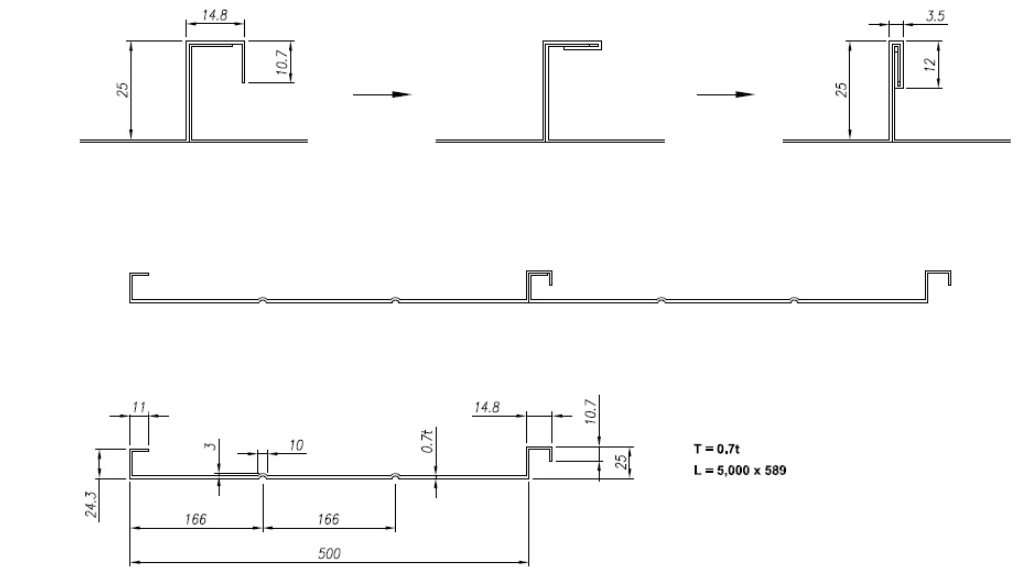

2. Roller Station The heart of the machine, the roller station consists of multiple sets of rollers designed to shape the steel into specific profiles. Adjustments can be made to accommodate different shapes and sizes.

3. Cutting Mechanism Once the roll forming process is complete, the cut-off section is usually determined by the length required for the final products. A cutting mechanism, either hydraulic or mechanical, accurately cuts the formed steel profile to the desired length.

4. Support Table After cutting, the formed sections are supported on a table for easy handling and packaging.

5. Control System Modern roll forming machines are equipped with advanced control systems that allow for precise adjustments and monitoring throughout the process. This increases production efficiency and product quality.

steel sheet roll forming machine

Advantages of Using Roll Forming Machines

1. Efficiency Roll forming is a continuous process, allowing for the production of long sections of product in a single run. This significantly reduces production time compared to traditional manufacturing methods.

2. Material Utilization The process generates minimal waste, as the entire width of the steel sheet can be used effectively.

3. Standardization High levels of consistency and repeatability are achieved, ensuring that each product meets strict quality standards.

4. Versatility Roll forming machines can produce a wide range of profiles, from simple shapes like angles and channels to complex cross-sections for specific applications.

5. Cost-Effectiveness Although the initial investment for a roll forming machine may be higher than other manufacturing tools, the long-term savings in labor and material costs make it a financially sound choice for many manufacturers.

Applications of Steel Sheet Roll Forming

Steel sheet roll forming machines are widely used in various industries. They are essential in the construction sector for creating roofing materials, wall panels, and structural components. In the automotive industry, roll-formed parts are utilized in frames, supports, and panels. Other applications include producing window frames, door frames, and components for appliances and furniture.

Conclusion

The steel sheet roll forming machine stands as a testament to modern manufacturing's ability to enhance productivity and efficiency. As manufacturers continue to seek ways to improve processes and reduce costs, the roll forming technique offers a viable solution. With ongoing advancements in technology, the capabilities of these machines are set to expand, further solidifying their role in the industrial landscape. Investing in a steel sheet roll forming machine not only boosts production capabilities but also aligns with sustainable manufacturing practices by minimizing waste and energy consumption. As industry demands evolve, these machines will undoubtedly play a crucial role in shaping the future of metal components manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025