Feb . 10, 2025 11:35

Back to list

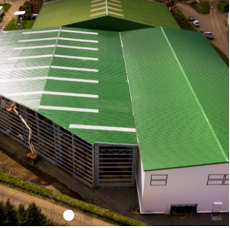

t18 metal roofing sheet roll forming machine

The steel sheet roll forming machine is revolutionizing the way industries approach the fabrication of metal components. These machines, integral in processes across sectors from automotive to construction, offer precise, efficient, and cost-effective solutions for manufacturing consistent metal profiles. Understanding the core capabilities and benefits of these machines not only enhances their effective use but also establishes a competitive edge for businesses.

In the realm of expertise, the strategic adoption of roll forming technology can significantly reduce operational costs. By minimizing human error and maximizing efficiency, these machines contribute to substantial labor and material savings. For example, the automotive industry, where margins are tight and efficiency is king, relies on roll forming for components like chassis frames and structural parts, where high strength-to-weight ratios are imperative. Authoritativeness in using roll forming machines arises from both theoretical knowledge and hands-on experience. Operators, engineers, and business leaders often engage in continual learning, keeping abreast of technological advancements and refinements in machine capabilities. This dedication to staying ahead and leveraging state-of-the-art technology reflects not only expertise but earns the trust and respect of clients and partners. Trustworthiness further manifests in adherence to stringent international quality standards. With ISO certifications and compliance to industry-specific regulations, businesses demonstrate their commitment to delivering excellence through roll-formed products. Transparency in operations, from the sourcing of materials to the algorithmic precision in manufacturing, builds confidence among stakeholders, ensuring long-term relationships and sustained business growth. In conclusion, the steel sheet roll forming machine is more than just equipment; it is a pivotal asset that combines experience, expertise, authoritativeness, and trustworthiness into one cohesive system. Its role in transforming manufacturing practices cannot be overstated, offering industries the tools required for innovation, quality, and economic success. By integrating these machines intelligently into production lines, companies can not only optimize their operations but also realize new potentials in product versatility and market reach.

In the realm of expertise, the strategic adoption of roll forming technology can significantly reduce operational costs. By minimizing human error and maximizing efficiency, these machines contribute to substantial labor and material savings. For example, the automotive industry, where margins are tight and efficiency is king, relies on roll forming for components like chassis frames and structural parts, where high strength-to-weight ratios are imperative. Authoritativeness in using roll forming machines arises from both theoretical knowledge and hands-on experience. Operators, engineers, and business leaders often engage in continual learning, keeping abreast of technological advancements and refinements in machine capabilities. This dedication to staying ahead and leveraging state-of-the-art technology reflects not only expertise but earns the trust and respect of clients and partners. Trustworthiness further manifests in adherence to stringent international quality standards. With ISO certifications and compliance to industry-specific regulations, businesses demonstrate their commitment to delivering excellence through roll-formed products. Transparency in operations, from the sourcing of materials to the algorithmic precision in manufacturing, builds confidence among stakeholders, ensuring long-term relationships and sustained business growth. In conclusion, the steel sheet roll forming machine is more than just equipment; it is a pivotal asset that combines experience, expertise, authoritativeness, and trustworthiness into one cohesive system. Its role in transforming manufacturing practices cannot be overstated, offering industries the tools required for innovation, quality, and economic success. By integrating these machines intelligently into production lines, companies can not only optimize their operations but also realize new potentials in product versatility and market reach.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products