steel roofing machine factories

The Rise of Steel Roofing Machine Factories Revolutionizing the Construction Industry

In recent years, the construction and building materials sector has undergone significant transformations, driven by advancements in technology and an increasing demand for durable, cost-effective materials. One of the most notable developments in this field is the emergence of steel roofing machine factories. These facilities not only enhance the efficiency of manufacturing processes but also contribute to sustainability and innovation in the construction industry.

The Importance of Steel Roofing

Steel roofing has become a popular choice for both residential and commercial buildings. Its advantages over traditional roofing materials are numerous. Steel roofs are known for their longevity, with a lifespan that often exceeds 50 years. They are also highly resistant to extreme weather conditions, including heavy rain, snow, and high winds. Furthermore, steel is non-combustible and provides excellent energy efficiency, reflecting sunlight and reducing cooling costs in hot climates.

The demand for steel roofing has surged, prompting manufacturers to increase production capacity. This surge has led to the establishment of specialized factories that produce advanced steel roofing machines, designed to streamline manufacturing processes while maintaining high quality and performance standards.

Features of Steel Roofing Machines

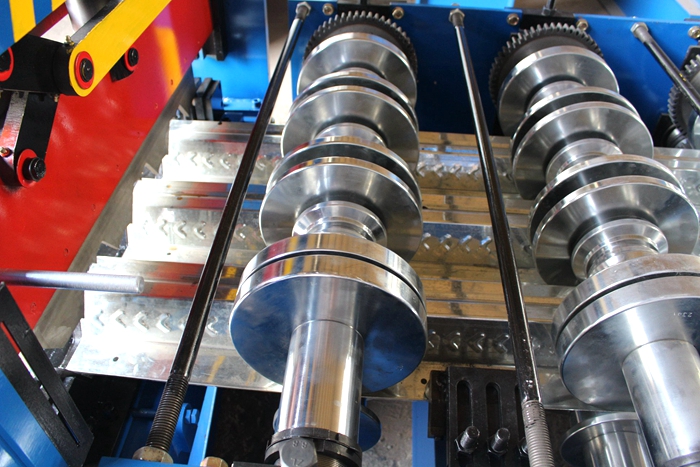

Steel roofing machine factories focus on producing equipment that can roll-form steel into roofing panels. These machines are equipped with cutting-edge technology that allows for quick setup, high production speeds, and precision engineering. Key features of these machines include

1. Roll Forming Technology This is the backbone of steel roofing machine production. Roll forming allows for continuous shaping of steel sheets into desired profiles without cutting waste, making it both economical and environmentally friendly.

2. Automated Systems Many modern steel roofing machines incorporate automation, which minimizes labor costs and maximizes output. These systems can also include computer numerical control (CNC) technology for precise cutting and shaping.

3. Customization Options Factories now offer machines that can produce a variety of roofing profiles, catering to different architectural styles and customer preferences. This flexibility helps manufacturers meet the diverse demands of the market.

steel roofing machine factories

4. Durability and Maintenance Steel roofing machines are built to withstand rigorous use in factory settings. They are designed with high-quality materials, ensuring durability and minimizing maintenance needs over time.

Economic Impact of Steel Roofing Machine Factories

The establishment of steel roofing machine factories has had a profound economic impact. Firstly, it has created numerous job opportunities in manufacturing, engineering, and management. Skilled labor is essential for operating complex machinery and ensuring high production standards.

Secondly, local economies benefit from the establishment of these factories through increased investment and infrastructure development. Suppliers and service providers also thrive as they cater to the needs of these factories, creating a ripple effect throughout the supply chain.

Environmental Considerations

The rise of steel roofing machine factories also aligns with global efforts to promote sustainable construction practices. Steel is a highly recyclable material, and many manufacturers incorporate recycled steel into their products. The production processes used in these factories aim to minimize waste and energy consumption, further enhancing their sustainability profile.

Additionally, steel roofing contributes to energy efficiency in buildings. With proper insulation, steel roofs can significantly reduce the need for heating and cooling systems, which in turn lowers carbon emissions associated with energy production.

Conclusion

The proliferation of steel roofing machine factories is a testament to the evolving landscape of the construction industry. As demand for durable, energy-efficient roofing solutions continues to grow, these factories play a crucial role in meeting market needs. By leveraging advanced technologies and adhering to sustainable practices, steel roofing machine factories are not only enhancing productivity and profitability but are also paving the way for a greener and more resilient future in construction. As we look ahead, the impact of these innovative facilities will undoubtedly shape the industry for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025