Steel Profile Roll Forming Equipment for Efficient Metal Fabrication and Production Solutions

The Evolution and Importance of Steel Profile Roll Forming Machines

Steel profile roll forming machines are essential equipment in the manufacturing industry, primarily used for producing various steel profiles with consistent precision and high efficiency. This process has become indispensable in sectors such as construction, automotive, and manufacturing, where high-strength materials and complex shapes are often required.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, typically a coiled sheet of steel, is passed through a series of rollers. Each roller in the sequence gradually shapes the metal into desired profiles such as C-sections, Z-sections, or custom configurations. This method offers a myriad of advantages, including minimal material waste, the ability to produce long lengths of profiles with uniformity, and high production rates.

Components of Steel Profile Roll Forming Machines

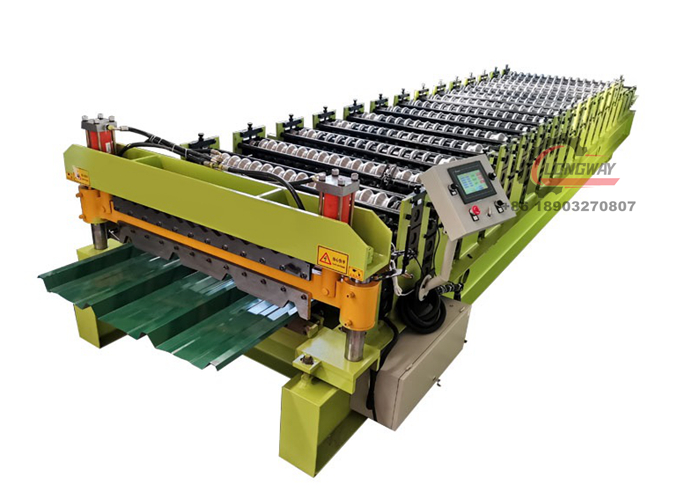

A typical roll forming machine consists of several key components an uncoiler, a feeding section, multiple sets of rollers, a cutting device, and a control system. The uncoiler unwinds the steel coil, which is then fed into the machine. The rollers, arranged sequentially, gradually form the specified profile. Depending on the design, some machines incorporate additional processes such as punching, notching, and embossing which can enhance the functionality of the finished product.

The cutting device, which can be either mechanical or hydraulic, is crucial for ensuring precise lengths of profiles as they exit the machine. Modern machines are often equipped with advanced control systems that incorporate PLC (Programmable Logic Controllers) for better regulation and automation of the entire process.

Benefits of Steel Profile Roll Forming Machines

steel profile roll forming machine

The advantages of using roll forming machines are manifold. First, they significantly improve production efficiency. Once set up, the machines can operate continuously and produce hundreds of meters of profiles per hour. Additionally, the process reduces material waste drastically, as it utilizes a continuous strip of metal and eliminates the need for extensive secondary operations.

Moreover, steel profile roll forming machines offer a high precision level that is difficult to achieve with other manufacturing methods. The consistent profile shapes and dimensions minimize discrepancies, ensuring that final products meet stringent industry standards.

Applications Across Industries

Steel profile roll forming machines find their application in various industries. In the construction sector, they are used to create components for metal buildings, roofing systems, and wall panels. In the automotive industry, roll forming produces parts like door frames and structural components that require strength and durability. Additionally, the machinery is vital in making HVAC (heating, ventilation, and air conditioning) components, electrical enclosures, and shelving systems.

Future Trends

As technology progresses, the future of steel profile roll forming is leaning towards further automation and customization. The integration of Industry 4.0 concepts, such as IoT (Internet of Things) and advanced monitoring systems, are enabling manufacturers to achieve greater flexibility and real-time control over production processes. Automation not only reduces labor costs but also enhances safety in manufacturing environments.

Conclusion

In summary, steel profile roll forming machines are crucial in the modern manufacturing landscape, providing efficient, cost-effective, and high-precision solutions for a myriad of applications. As industries evolve and embrace new technological advancements, the role of these machines will undoubtedly expand, shaping the future of metalworking and construction. The ongoing innovation in this field ensures that these machines will remain at the forefront of manufacturing excellence for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025