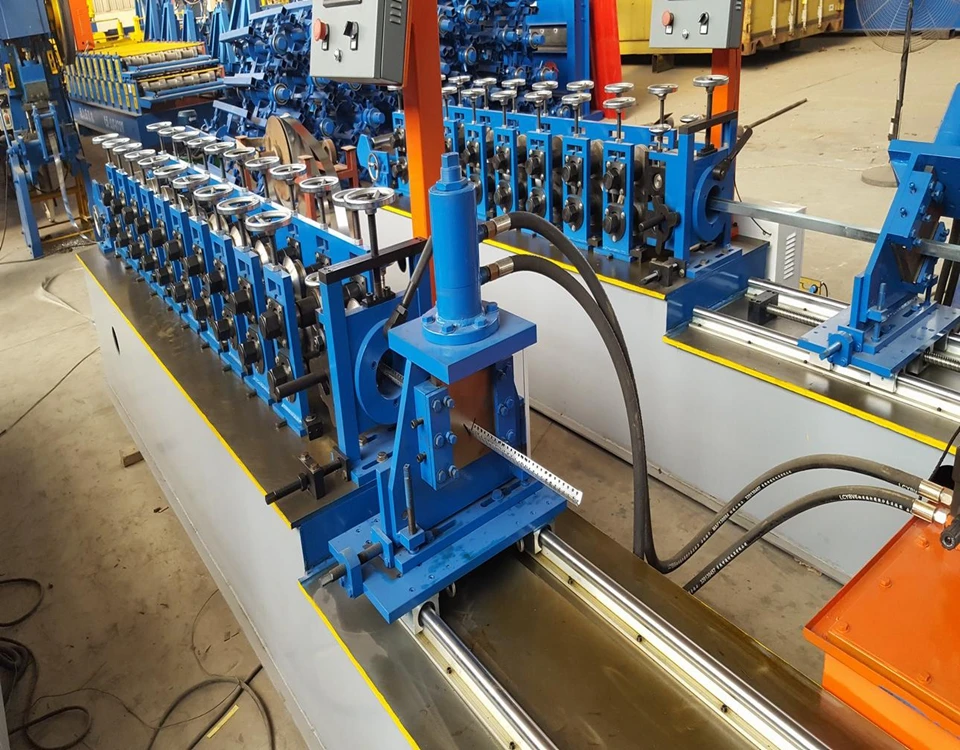

steel frame roll forming machine manufacturer for efficient metal fabrication solutions

The Evolution and Benefits of Steel Frame Roll Forming Machines

In the ever-evolving world of construction and manufacturing, efficiency, durability, and sustainability are paramount. One of the most innovative solutions that have emerged to address these needs is the steel frame roll forming machine. This sophisticated machinery represents a significant advancement in the production of steel frames, widely used in various construction applications, ranging from residential buildings to commercial establishments.

Understanding Roll Forming Technology

Roll forming is a continuous process in which a long strip of metal, usually steel, is gradually bent into desired shapes through a series of rollers. The process is highly efficient and can produce components with consistent quality and precision. Steel frame roll forming machines are designed specifically for producing structural steel frames, which serve as the skeleton for buildings and other structures.

The Manufacturing Process

The process begins with the feeding of flat steel sheets or coils into the machine. As the material passes through the series of rollers, it undergoes shaping and bending, ultimately forming a frame profile. Once the profile is formed, it can be cut to specific lengths or assembled as part of a larger structure.

One of the key advantages of using steel frame roll forming machines is the reduction in labor costs and production time. Traditional methods of frame construction often involve labor-intensive techniques that can lead to delays and increased expenses. In contrast, roll forming offers a streamlined, automated solution that enhances productivity.

Advantages of Steel Frame Construction

1. Strength and Durability Steel frames are known for their unmatched strength and durability. They can withstand extreme weather conditions and seismic activity, making them an ideal choice for buildings in diverse geographical locations.

steel frame roll forming machine factory

2. Lightweight Yet Strong Steel frames are lightweight compared to traditional building materials such as concrete. This property reduces the overall weight of structures, making them easier and less costly to transport. Additionally, the lightweight nature does not compromise structural integrity.

3. Sustainability With growing concerns over environmental impact, steel's recyclability has made it a preferred choice among environmentally conscious builders. Steel can be recycled multiple times without degrading its quality, thus contributing to sustainable construction practices.

4. Design Flexibility Steel frame roll forming machines allow for a high degree of customization. Architects and engineers can design unique shapes and sizes based on their specific project needs. This flexibility not only enhances aesthetic appeal but also aids in meeting functional requirements.

5. Speedy Construction The rapid production rates made possible by roll forming technology significantly decrease project timelines. This accelerated pace of construction is particularly advantageous in today’s fast-paced market, where time is a crucial factor.

Applications Across Industries

Steel frame roll forming machines find applications across various sectors, including residential, commercial, and industrial construction. They are extensively used in the construction of warehouses, factories, office buildings, and residential homes. The ability to produce different frame shapes in large quantities makes these machines indispensable in modern construction.

Conclusion

The steel frame roll forming machine marks a revolutionary step forward in the efficiency and effectiveness of steel frame production. With its myriad advantages, including strength, sustainability, and design flexibility, it is no wonder that this technology is gaining traction in the construction industry. As demand for faster and more durable building solutions continues to grow, the role of steel frame roll forming machines will undoubtedly become more prominent, driving innovations in construction and reshaping the skyline of our cities for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025